Bamboo strip edge polishing device

An edge and bamboo strip technology, which is applied to grinding machines, parts of grinding machine tools, and grinding/polishing equipment, etc., can solve the problems of low grinding efficiency of bamboo strip edges, high labor intensity of processing personnel, easy injury and self-injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments of the specification:

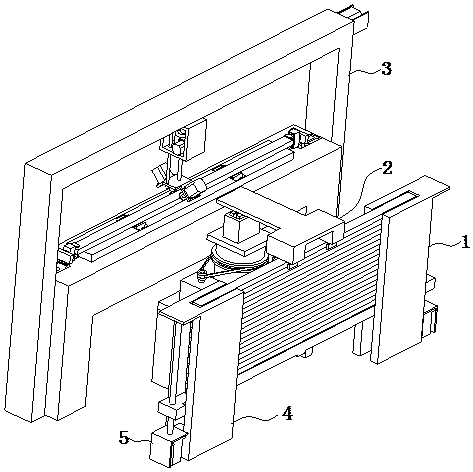

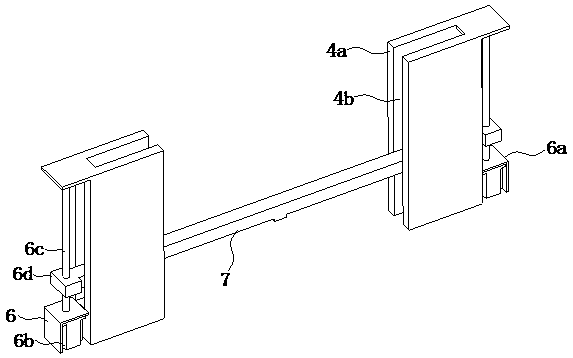

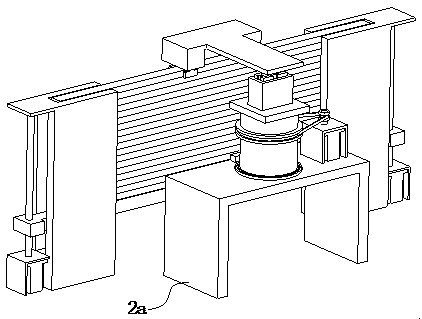

[0028] Reference Figure 1 to Figure 10 The bamboo strip edge polishing device shown includes a feeding mechanism 1, a material moving mechanism 2 and a grinding mechanism 3. The material moving mechanism 2 is located between the feeding mechanism 1 and the grinding mechanism 3. The feeding mechanism 1 It includes a storage component 4 and a material lifting component 5. The material lifting component 5 includes a first material lifting component 6 and a second material lifting component 6a that are symmetrically arranged on both sides of the material storage component 4, and the polishing mechanism 3 includes a bearing The pallet 8, the clamping component 9, the turning component 10, the supporting component 11 and the polishing component 12, the supporting table 8 is a rectangular parallelepiped structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com