Machining equipment with energy-saving effect for aluminum alloy profiles for doors and windows

A technology for aluminum alloy profiles and processing equipment, applied in metal processing equipment, metal sawing equipment, manufacturing tools, etc., can solve the problems of affecting processing efficiency, inconvenient use, time-consuming and laborious, etc., to facilitate processing operations, increase contact area, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

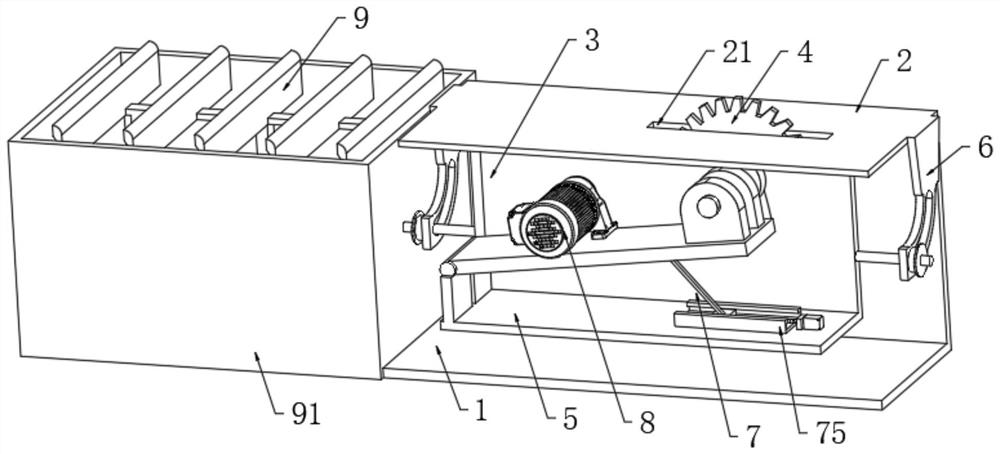

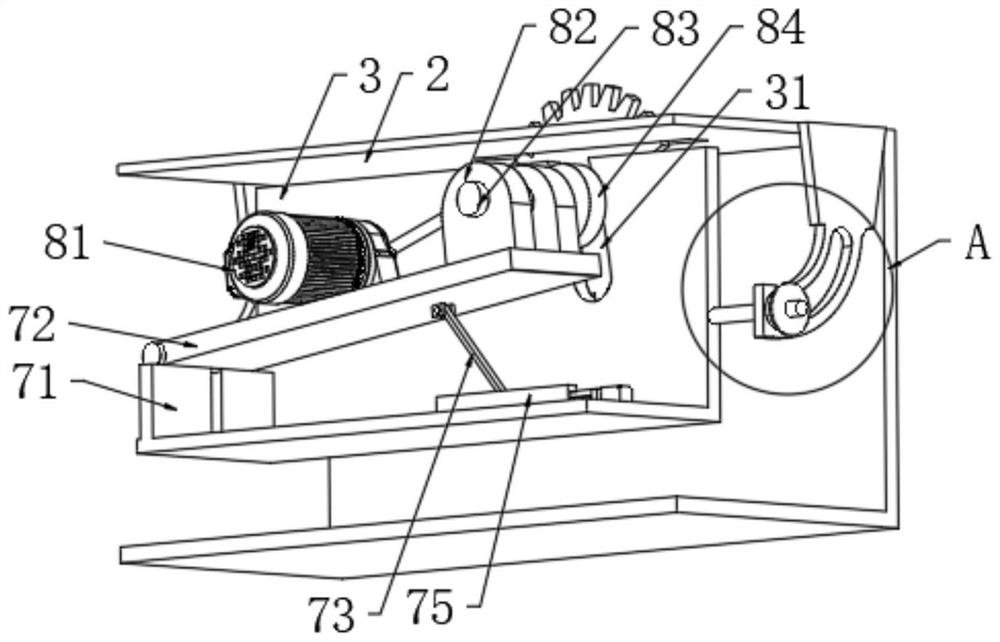

[0033] see Figure 1-6 , an energy-saving processing equipment for aluminum alloy profiles for doors and windows, which is composed of a base 1, a longitudinal plate 3 and a feeding device 9;

[0034] Wherein, in order to carry out limit support to the whole, be provided with base 1, the top of base 1 is provided with the processing plate 2 that is fixedly welded, and the middle part of processing plate 2 has cutting groove 21, and cutting groove 21 runs through processing plate 2 longitudinally, facilitates Processing of aluminum alloy profiles;

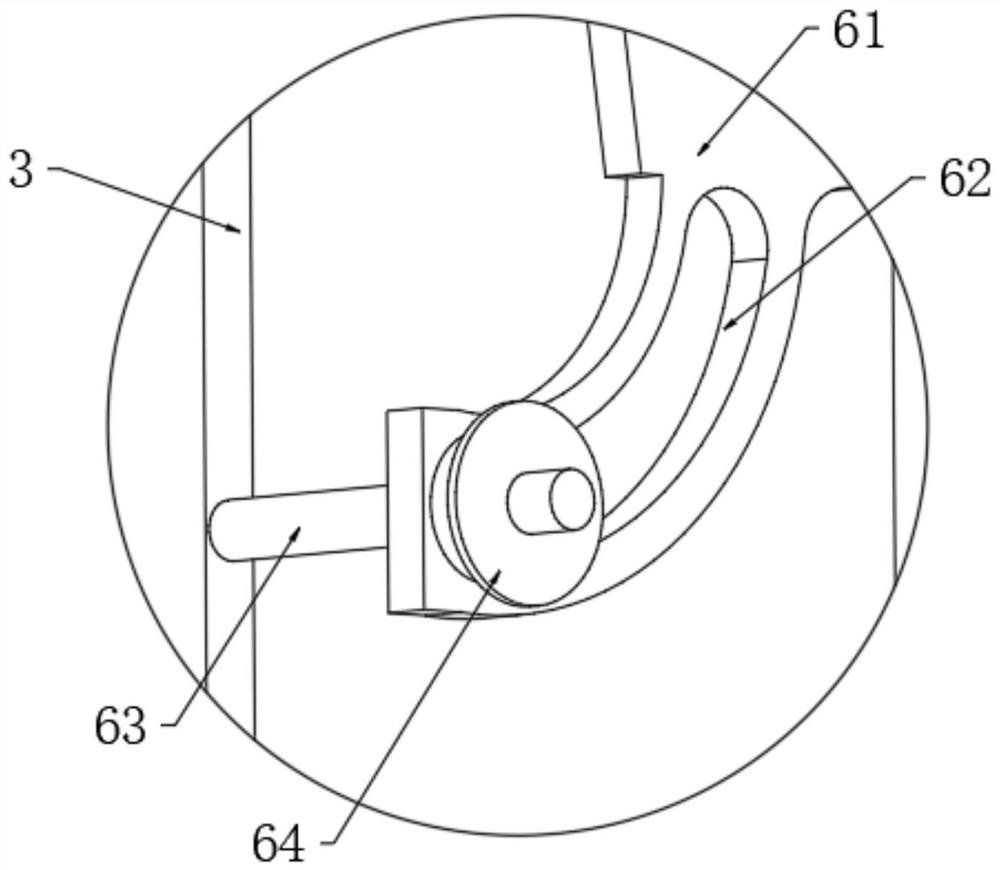

[0035] Among them, in order to adjust the cutting angle and cutting height, a longitudinal plate 3 is provided, which is located below the processing plate 2. The upper limit of the longitudinal plate 3 is movably connected with a sawtooth 4. The sawtooth 4 is used for cutting aluminum alloy profiles. The processing plate 2 An angle adjustment device 6 is fixed at the position corresponding to the longitudinal plate 3, and the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com