A feeding device with guiding function for high imaging tempered glass furnace

A tempered glass and imaging technology, which is applied in glass tempering, glass transportation equipment, glass manufacturing equipment, etc., can solve problems affecting the process, glass breakage, collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

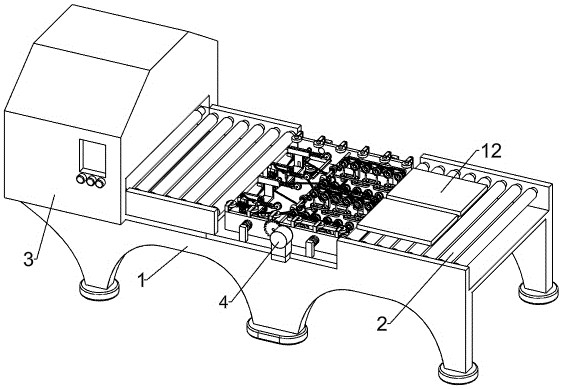

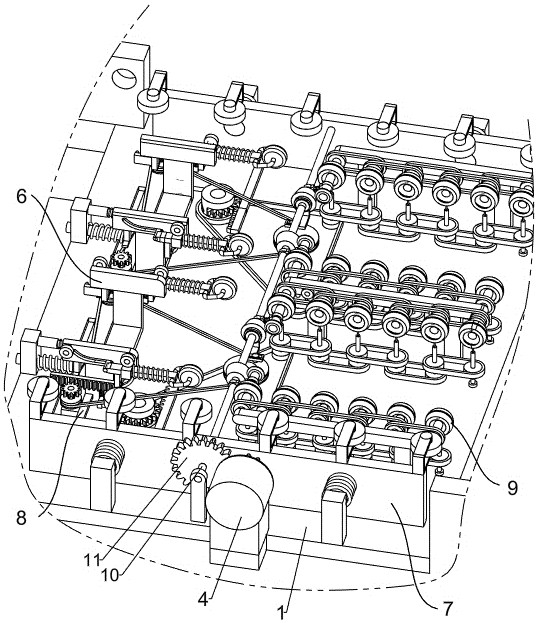

[0030] A feeding device with a guiding function for a high-image tempered glass furnace, such as figure 1 and figure 2 As shown, it includes an operating table 1, a roller 2, a tempering furnace 3, a reduction motor 4, a first gear 5, an induction mechanism 6, a lateral movement mechanism 7, a steering adjustment mechanism 9, a rotating shaft 10 and a third gear 11, the roller 2 Several are a group, and two groups are arranged symmetrically before and after, the rollers 2 in the two groups are respectively connected with the power mechanism, the rotation direction of the rollers 2 in the two groups is counterclockwise, and the rollers 2 in the two groups are respectively arranged at On the operating table 1, a tempering furnace 3 is arranged on the left part of the operating table 1, a reduction motor 4 is fixedly connected to the front side of the middle part of the operating table 1, a first gear 5 is fixedly connected to the output shaft end of the reduction motor 4, and t...

Embodiment 2

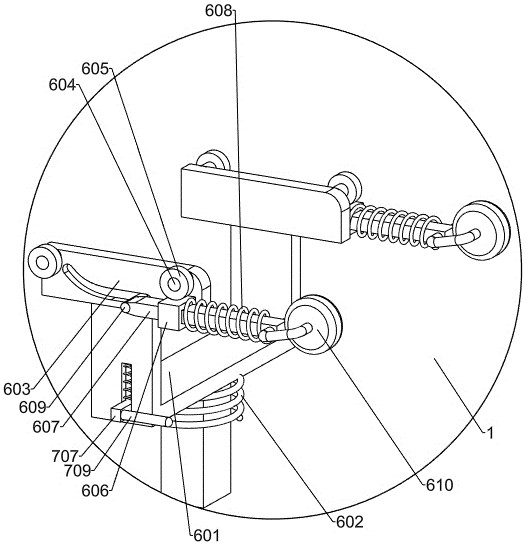

[0033] On the basis of Example 1, as image 3 As shown, the induction mechanism 6 includes a first U-shaped frame 601, a first spring 602, a first fixed block 603, a fixed shaft 604, a first pulley 605, a rectangular block 606, a first sliding rod 607, a second spring 608, The first limit rod 609 and the second pulley 610, a first U-shaped frame 601 is slidably arranged on the upper part of the operation table 1, a T-shaped chute is opened on the front side of the first U-shaped frame 601, and the first U-shaped frame 601 is connected to the operation table. A first spring 602 is fixedly connected between 1 and 1, and two first fixing blocks 603 are symmetrically arranged in the front and rear. The sides are respectively provided with arc-shaped chutes, the outer sides of the two first fixing blocks 603 are respectively fixed with two fixing shafts 604, the outer sides of the four fixing shafts 604 are rotatably provided with first pulleys 605, and the two first fixing blocks ...

Embodiment 3

[0046] On the basis of Example 2, as Image 6 As shown, it also includes limit components 8, two limit components 8 are symmetrically arranged in the front and rear, and the two limit components 8 are respectively located between the adjacent induction mechanism 6 and the lateral movement mechanism 7, and the limit component 8 includes a support A rod 801, a third sliding rod 802, a fifth spring 803 and a second limiting plate 804, a support rod 801 is fixedly connected to the front side of the first fixing block 603, and a third sliding rod 802 is slidably arranged at the front of the support rod 801. The lower part of the third sliding rod 802 is cylindrical, the fifth spring 803 is fixedly connected between the lower part of the third sliding rod 802 and the support rod 801, the second limiting plate 804 is fixedly connected to the left part of the rear side of the first limit plate 712, The rear of the second limiting plate 804 is provided with a through hole that cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com