Ceramic anilox roller packaging equipment

A technology of packaging equipment and ceramic mesh, applied in the field of ceramic anilox roller packaging equipment, can solve the problems of uniform coating and low efficiency, and achieve the effect of improving the lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

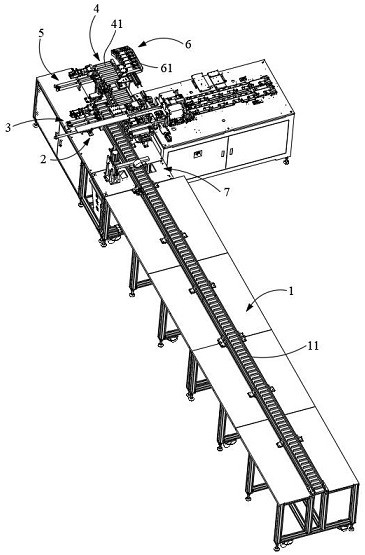

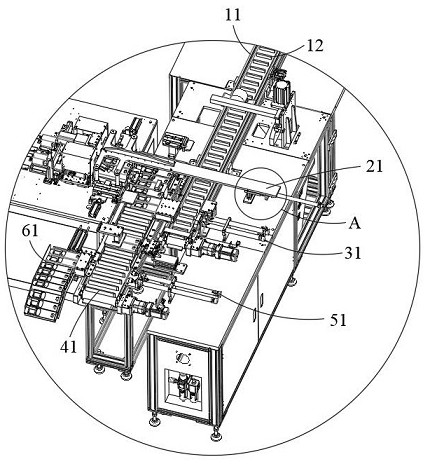

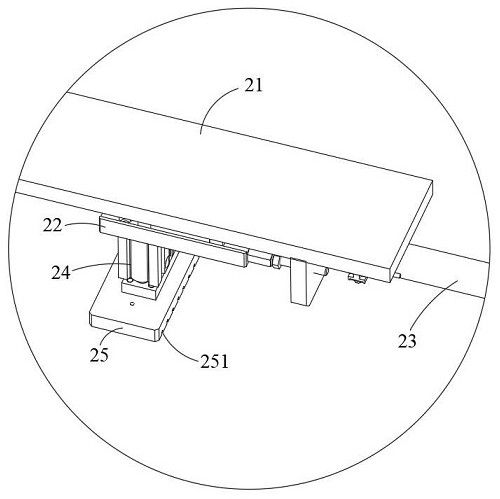

[0038] In this example, if Figure 1 to Figure 6 As shown, this embodiment provides a ceramic anilox roll packaging equipment, which includes: a first conveying mechanism 1, an oiling mechanism 2, a first transferring mechanism 3, a second conveying mechanism 4, a second transferring mechanism 5 and a finished product A collection mechanism 6; wherein the oiling mechanism 2 is movable above the first conveying mechanism 1, the first transfer mechanism 3 and the second conveying mechanism 4 are respectively located on both sides of the end of the first conveying mechanism 1, and the first conveying mechanism 4 The second transfer mechanism 5 and the finished product collection mechanism 6 are respectively located on both sides of the end of the second conveying mechanism 4; The anilox roller moves laterally to spread the lubricating oil on the surface of the anilox roller; the first transfer mechanism 3 pushes the corresponding anilox roller at the end of the first conveying me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com