Building brick clamping device

A clamping device and brick technology, applied in the direction of manual conveying device, transportation and packaging, etc., can solve the problems of inability to support, achieve the effect of convenient clamping operation, avoid tilting, and save grip force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

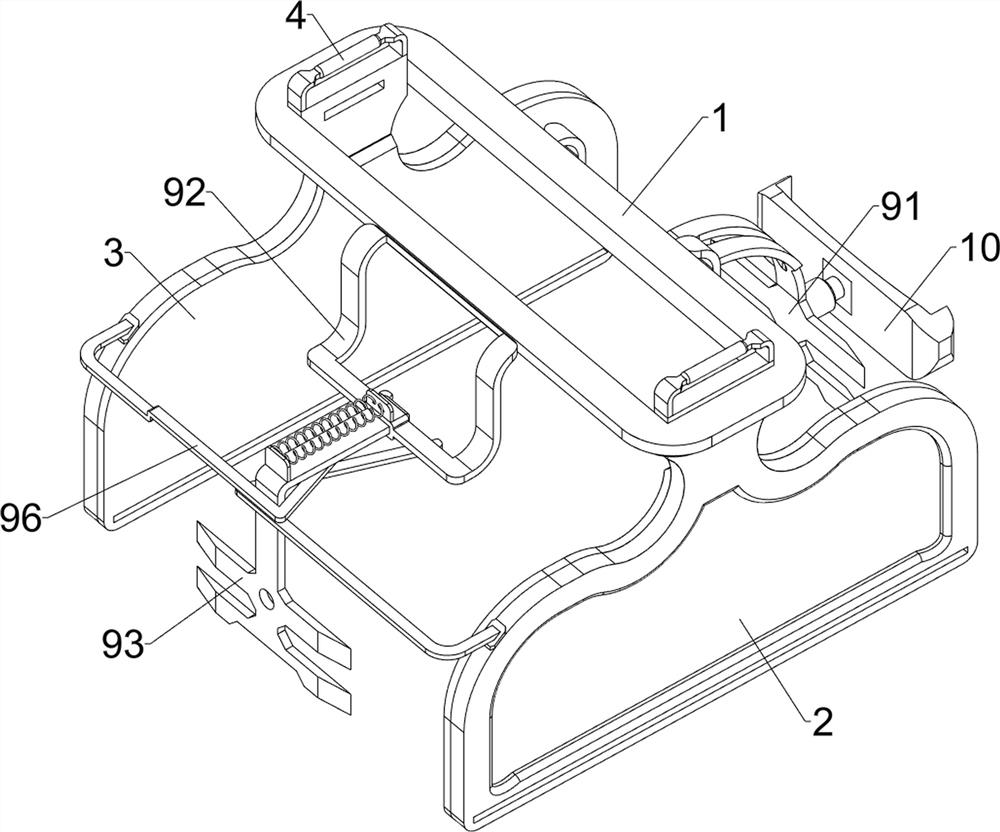

[0031] A clamping device based on construction bricks, such as figure 1 , Figure 4 and 5 As shown, it includes a fixed plate 1, a first connecting plate 2, an anti-skid plate 3, a first handle 4, a clamping mechanism 5 and a blocking mechanism 7, and the left and right symmetrical slides on the fixed plate 1 are provided with the first connecting plate 2, and the fixed plate 1 is made of aluminum alloy, which is light in weight and relatively hard in strength. Anti-skid plates 3 are bolted on the opposite sides of the two first connecting plates 2, and first handles are bolted on the upper sides of the two first connecting plates 2. 4. The fixing plate 1 is provided with a clamping mechanism 5, and the first connecting plate 2 is provided with a blocking mechanism 7 for supporting building bricks.

[0032] Such as Figure 4 As shown, the clamping mechanism 5 includes a second connecting plate 51, a second handle 52, a first spring 53, a first guide rod 54, a third connecti...

Embodiment 2

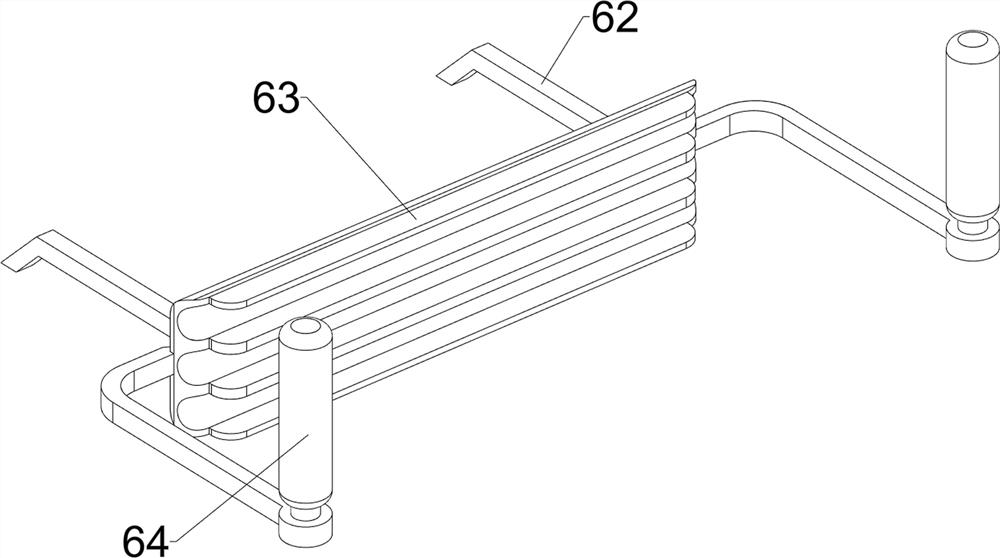

[0036] On the basis of Example 1, such as Figure 1-3 As shown, it also includes a clamping mechanism 6. The clamping mechanism 6 includes a first fixed frame 61, a second guide rod 62, a clamping plate 63 and an armrest 64, and the top front side of the second connecting plate 51 is bolted to the first Fixing frame 61, on the first fixing frame 61 sliding type runs through two second guide rods 62, between the two second guide rods 62 rear sides is welded with clamping plate 63, has on the clamping plate 63 and the third The card slot in contact with the connecting plate 55 and the left and right sides of the card position plate 63 are symmetrically provided with handrails 64 .

[0037] When the operator uses the second handle 52 as a fulcrum to pull the stay rope 57 upwards through the third connecting plate 55, the operator can drive the locking plate 63 to move backward through the handrail 64, so that the locking groove on the locking plate 63 will be connected to the thi...

Embodiment 3

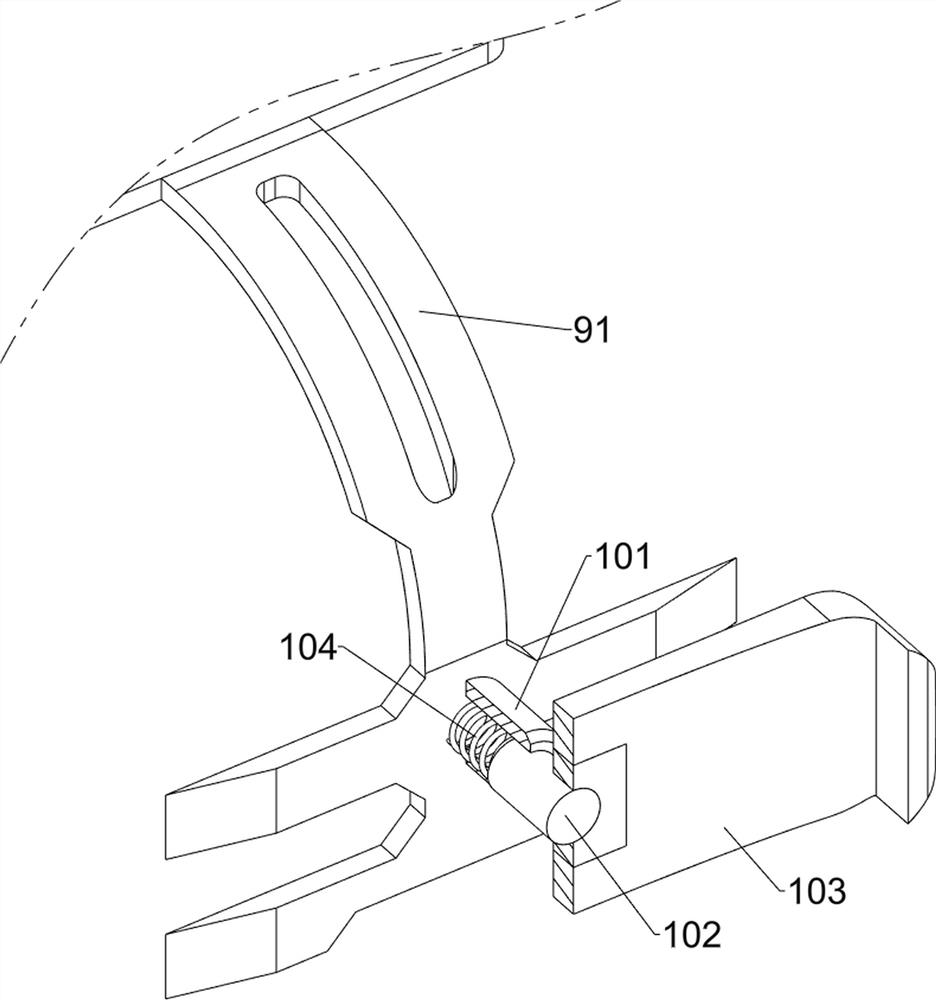

[0039] On the basis of Example 2, such as figure 1 , Figure 5 and Figure 6 As shown, a power mechanism 8 is also included. The power mechanism 8 includes an elastic rod 81, a second fixing frame 82 and a second spring 83. Two first baffle plates 72 are connected to the first connecting plate 2 on the same side. Two springs 83, two first baffle plates 72 on the side away from each other are equipped with elastic rods 81 symmetrically front and back, and the left and right symmetrical formula bolts on the lower side of the fixed plate 1 are connected with the second fixed mount contacting with the elastic rods 81 on the same side 82.

[0040] At first, the second fixing frame 82 clamps the elastic rod 81, and the second spring 83 is in a stretched state. When the operator makes the two first connecting plates 2 approach, since the first baffle plate 72 has opened and closed to the limit position, Therefore, the swash plate 71 at this time will drive the elastic rods 81 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com