Washing air purification device

An air and airflow technology, applied in the field of air purification devices for washing and removing harmful substances in the air, can solve the problems of high cost, easy water leakage, corrosion of electrical components, etc., to increase the mixing space and time, increase the probability of production, occupy Small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

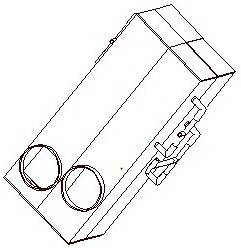

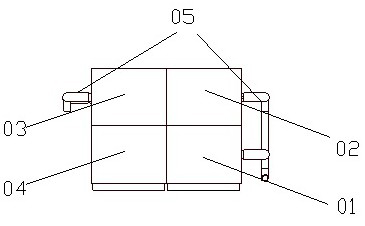

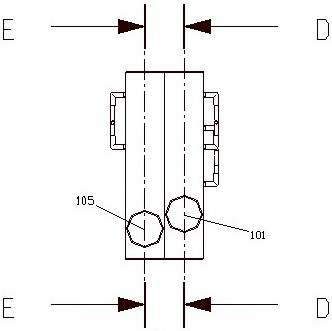

[0044] Embodiment 1: see Figure 1 ~ 7 As shown in figure, a set of rectangular pipe components arranged in close contact with 2x2 water washing to remove harmful substances in the air. Figure 1It is the three-dimensional schematic diagram of the pipeline assembly, including the pipeline, sprinkler head, high-pressure water pipe and the water removal device arranged in the last pipeline. Figure 2 It is a top view of the pipe assembly, including pipe 01, pipe 02, pipe 03, pipe 04 and peripheral high-pressure water pipeline 05. An air inlet 101 is arranged at the lower end of the side of the pipe 01, and an air outlet 105 is arranged near the lower end on the same side of the pipe 04. A pair of communication holes 102 are arranged on the side of the pipe 01 in contact with the pipe 02; The lower end of the contact surface between pipe 02 and pipe 03 is provided with a connecting hole 103, the upper end of the contact surface between pipe 3 and pipe 4 is provided with a connecting hol...

Example Embodiment

[0049] Embodiment 2: similar to embodiment 1, the pipe assembly with 2x2 layout is still taken as an example. The difference is the setting between the pipe assembly and the water tank. The lower end of the pipe assembly adopts an integral end cover to close the lower channel.

[0050] as Figure 8 As shown in, a fixing frame 06 is arranged on the pipe assembly, which is symmetrically arranged. The holder 06 can be hung on the air purifier housing, so that the pipe assembly is suspended. The lower end of the pipe assembly is provided with a buckle 07, which is integrally buckled on the outside of the pipe assembly. The clip 07 is provided with a return pipe 08. Under the pipe assembly, a horizontally movable water tank 09 is placed. The spray water will converge into the buckle 07 and then return to the water tank through the return pipe 08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com