Method for controlling content of crystal water in hydrate and application

A technology of hydrate and crystal water, which can be used in measurement devices, instruments, analytical materials, etc., and can solve the problem that the content of crystal water of hydrate is difficult to effectively control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The purpose of this embodiment is to obtain building gypsum. According to the ideal crystal water content of building gypsum is 5.27%, then the target crystal water content after calcination in this embodiment is set to 5.27%.

[0061] (1) Change relationship construction

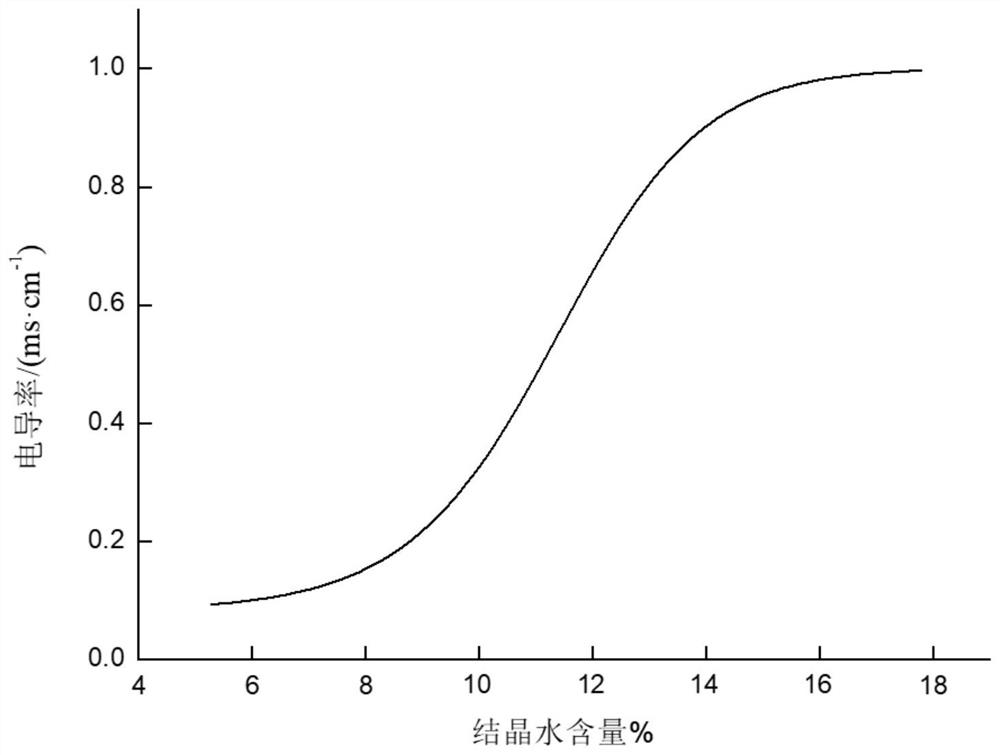

[0062] Take a small amount of the gypsum to be treated, and measure the relationship F(x) between its electrical conductivity and crystal water through experiments under laboratory conditions. After 2-5 minutes, take it out and measure its conductivity and crystal water data; repeat this operation until the crystal water is lower than 0.1. Take the crystal water content (unit: weight %) as the abscissa, and take the electrical conductivity (unit: ms / cm) as the ordinate to draw a scatter diagram, such as figure 1 Shown, with computer fitting function equation F(x), F(x)=1.00093+0.92052 / (1+exp(x-x 0 ) / dx)), R 2 =0.9957,x 0 is the crystal water content in the gypsum to be treated.

[0063] (2) Prep...

Embodiment 2

[0078] The same gypsum as in Example 1 was selected, except that the target crystal water content in this example was 8.00%. This embodiment is used to embody the method of the present invention, which can obtain gypsum products with any crystal water content as required, so that it can be applied to various application modes.

[0079] (1) The variation relationship F(x) is the same as that in Example 1.

[0080] (2) Use the same rotary kiln and monitoring points as in Example 1. According to the initial crystal water content and the target crystal water content, set N 2 The target crystal water content is 14.1%, N 3 The target crystal water content is 11.65%, N 4 The target crystal water content is 9.94%, N 5 The target crystal water content is 8.14%. According to the functional relationship F(x) between the conductivity of the hydrate and the water of crystallization, N 2 to N 5 Respectively corresponding target conductivity R 2 to R 5 They are 0.9087, 0.6141, 0.317...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com