Adjustable door foaming mold equipment

A foaming mold, adjustable technology, applied in the field of adjustable door body foaming mold equipment, can solve problems such as mold expansion, lack of fixing plates at mold joints, waste of energy, etc., to save labor, facilitate demoulding, The effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

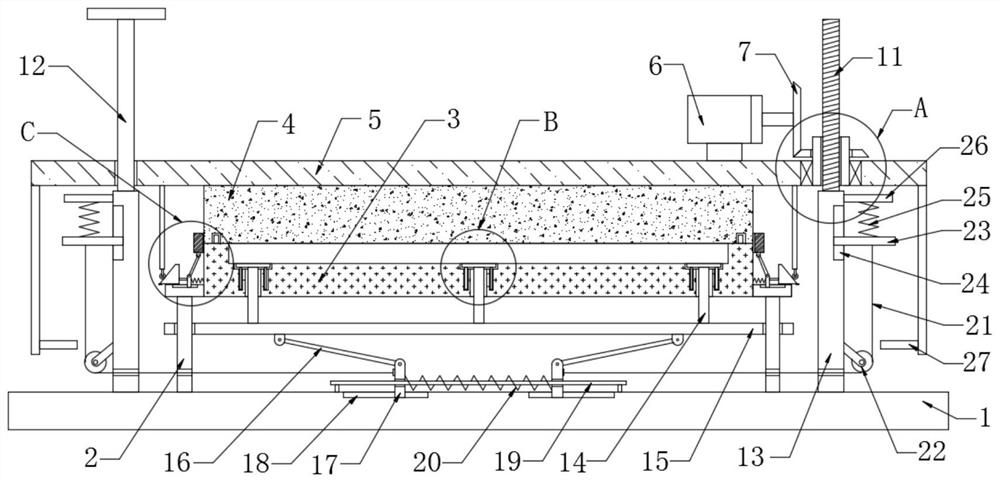

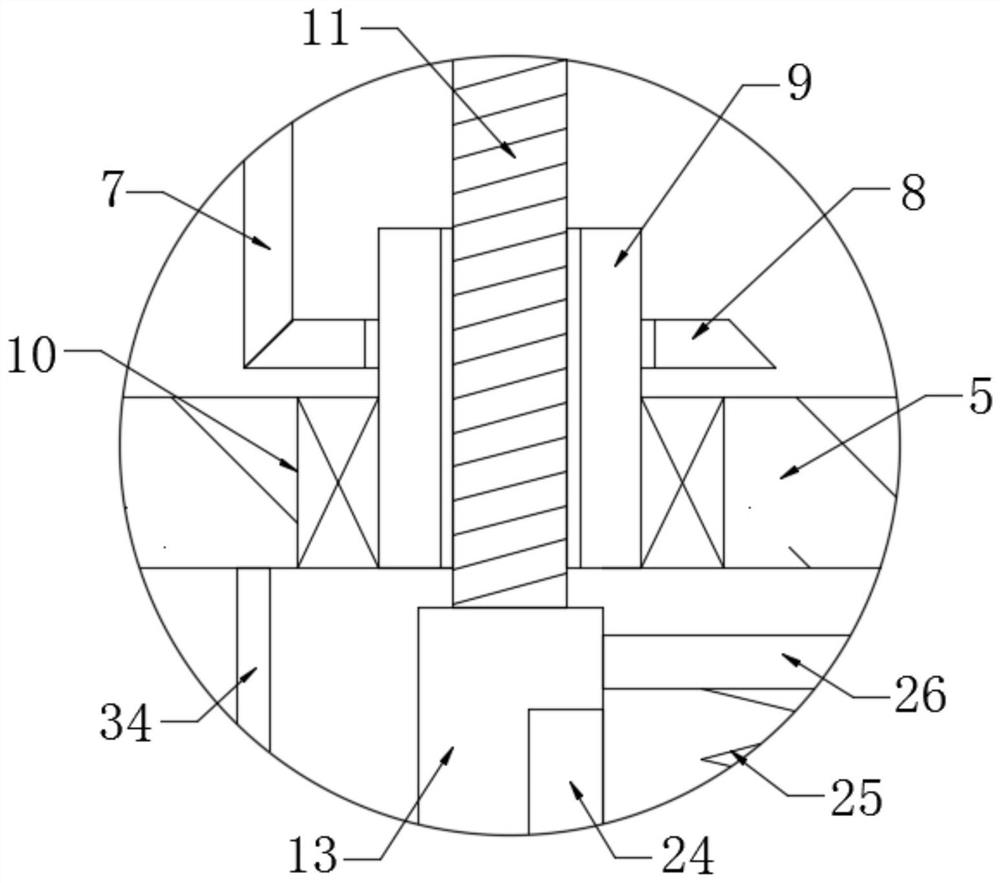

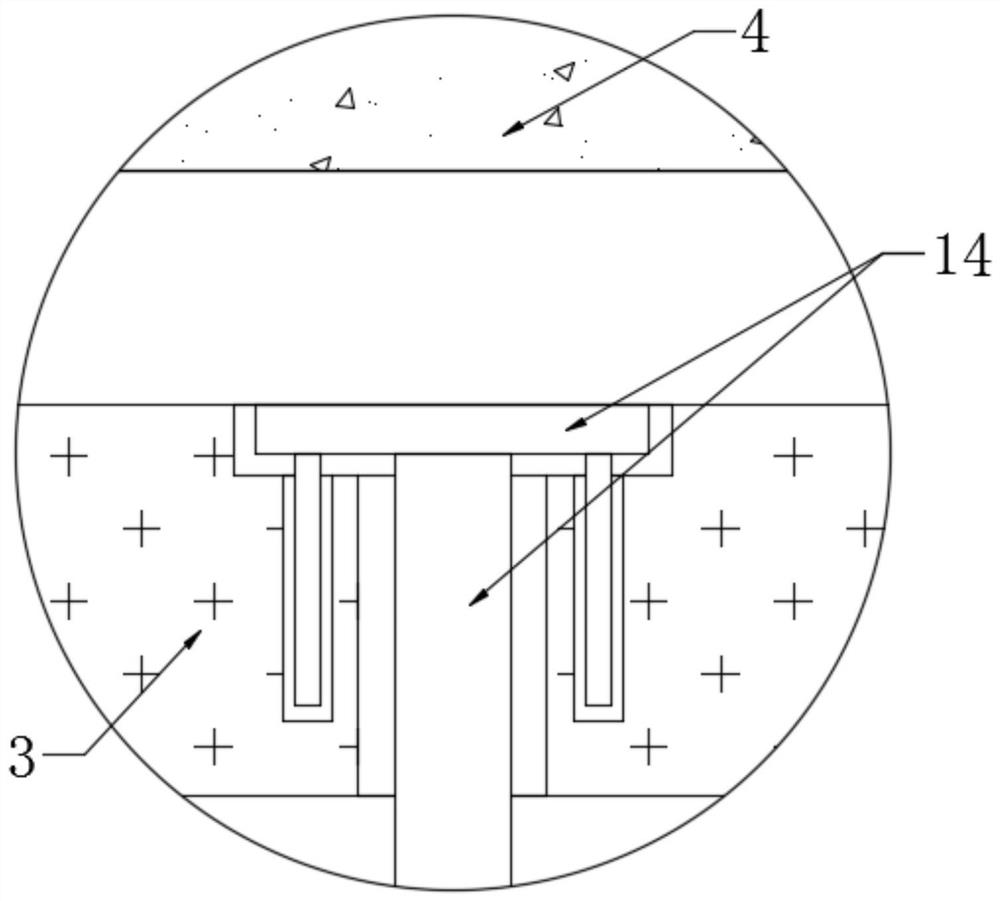

[0023] refer to Figure 1-4 , an adjustable door body foaming mold equipment, including a base 1, a support base 2 is fixedly installed on the left and right sides of the upper end of the base 1, and a lower mold 3 is fixedly installed at the ends of the support base 2 close to each other, and the upper side of the lower mold 3 is provided There is an upper mold 4, and the lower mold 3 and the upper mold 4 are attached to each other. The upper end of the upper mold 4 is fixedly installed with a lifting plate 5, and the upper end of the lifting plate 5 is fixedly connected with a motor 6. Gear 1 7 is meshed with bevel gear 2 8, and bevel gear 2 8 is fixedly connected with threaded sleeve 9, and the outside of threaded sleeve 9 is fixedly connected with bearing 10, and the outside of bearing 10 is fixedly connected with lifting plate 5, and threaded sleeve 9 is rotatably connected to lift Plate 5, screw rod 11 is threadedly connected on the inner side of threaded sleeve 9, slidi...

Embodiment 2

[0025] refer to Figure 1-4 , in this embodiment, it is basically the same as Embodiment 1. What is more optimized is that a sleeve plate 28 is set on the outer side of the connection between the lower mold 3 and the upper mold 4, and two connecting rods are hinged on the left and right sides of the lower end of the sleeve plate 28. 29, the lower end of connecting rod 2 29 is hinged with slider 2 30, and the upper end of support seat 2 is provided with chute 3 31 corresponding to slider 2 30, and slider 2 30 is slidably connected to support seat 2, and one end of slider 2 30 close to each other is fixedly connected There is a spring three 32, the other end of the spring three 32 is fixedly connected to the lower mold 3, and one end of the slide block two 30 is fixedly installed with a swash plate 33, and the sides of the swash plate 33 that are far away from each other are provided with rollers 34. The plates 33 are attached to each other, the upper end of the roller 34 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com