Hot rolling coiler side guide plate control method capable of improving coiling quality

A control method and technology of side guide plates, which are applied in the field of hot coil rolling, can solve problems such as side guide plates affecting coil quality, and achieve the effects of improving coil quality, avoiding equipment damage, and preventing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

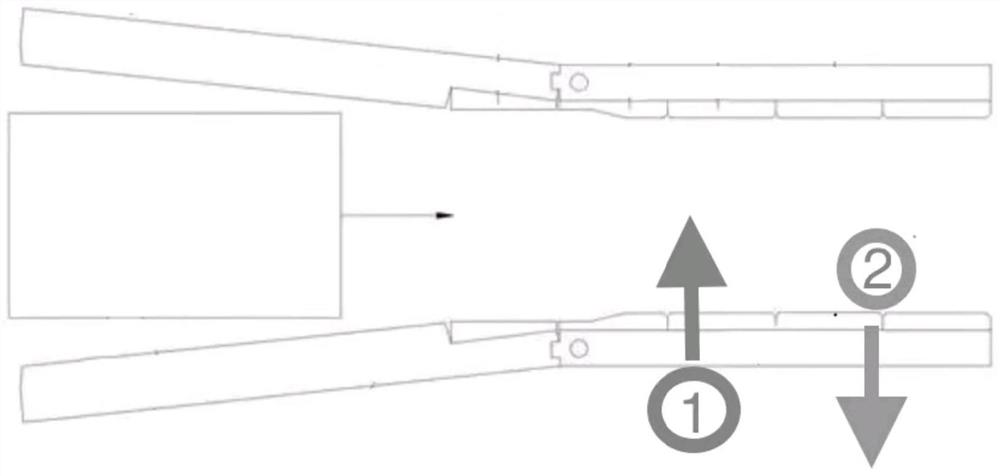

[0022] The method for controlling the side guide plate of a hot-rolled coiler that can improve the coil quality according to the present invention includes the following steps:

[0023] (1) In this embodiment, a strip with a width of 1220 mm is produced, and the hot rolling coiler is used for hot rolling. When the strip head reaches the middle position of the length of the side guide plate of the hot rolling coiler, a short stroke of 80 mm is carried out. When the roller bites the steel, the second short stroke is 20mm;

[0024] (2) When the reel bites the steel, the side guide plate is closed with a position margin of 10mm, and the remaining pressure margin is 10mm, and the strip steel is clamped on both sides of the side guide plate. When the pressure reaches 70% of the secondary set pressure, the side guide plate is one The side does not change into position control, and the other side is clamped to reach the secondary set pressure;

[0025] (3) Take the effective referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com