Drive and control circuit for impact force increasing of needle type printing head and control method of drive and control circuit

A technology for driving control circuits and dot print heads, applied in printing devices, printing, etc., can solve the problem of high heat generation in the release module, and achieve the effects of increasing the impact force, improving the printing effect, and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

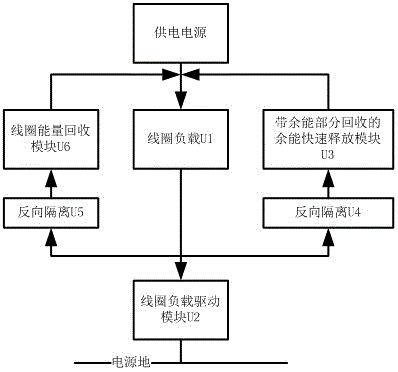

[0028] This embodiment provides a drive control circuit for a dot-type print head to increase the striking force, such as image 3 As shown, it includes a power supply, a coil load module U1, a coil load drive module U2, a residual energy quick release module U3 for partial recovery of residual energy, a second reverse isolation module U4, a first reverse isolation module U5 and Coil energy recovery module U6; the input end of the power supply is connected to one end of the coil load module U1, the other end of the coil load drive module U1 is connected to the input end of the coil load drive module U2, and the coil The output terminal of the load driving module U2 is connected to the input terminal of the second reverse isolation module U4 and the input terminal of the first reverse isolation module U5, and the output terminal of the second reverse iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com