Automobile sealing strip assembly with self-pressing function

A technology of automotive sealing strips and sealing strips, which is applied in the direction of engine sealing, vehicle parts, sealing devices, etc., can solve the problem that the sealing strip cannot squeeze the plate spontaneously, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

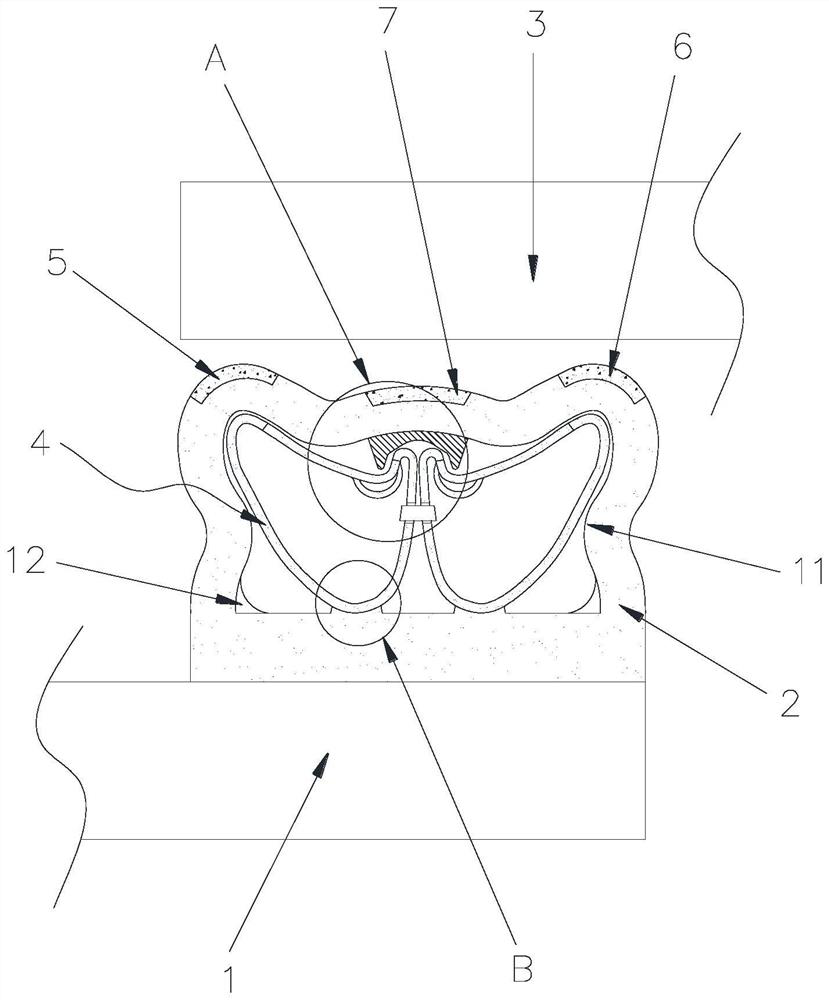

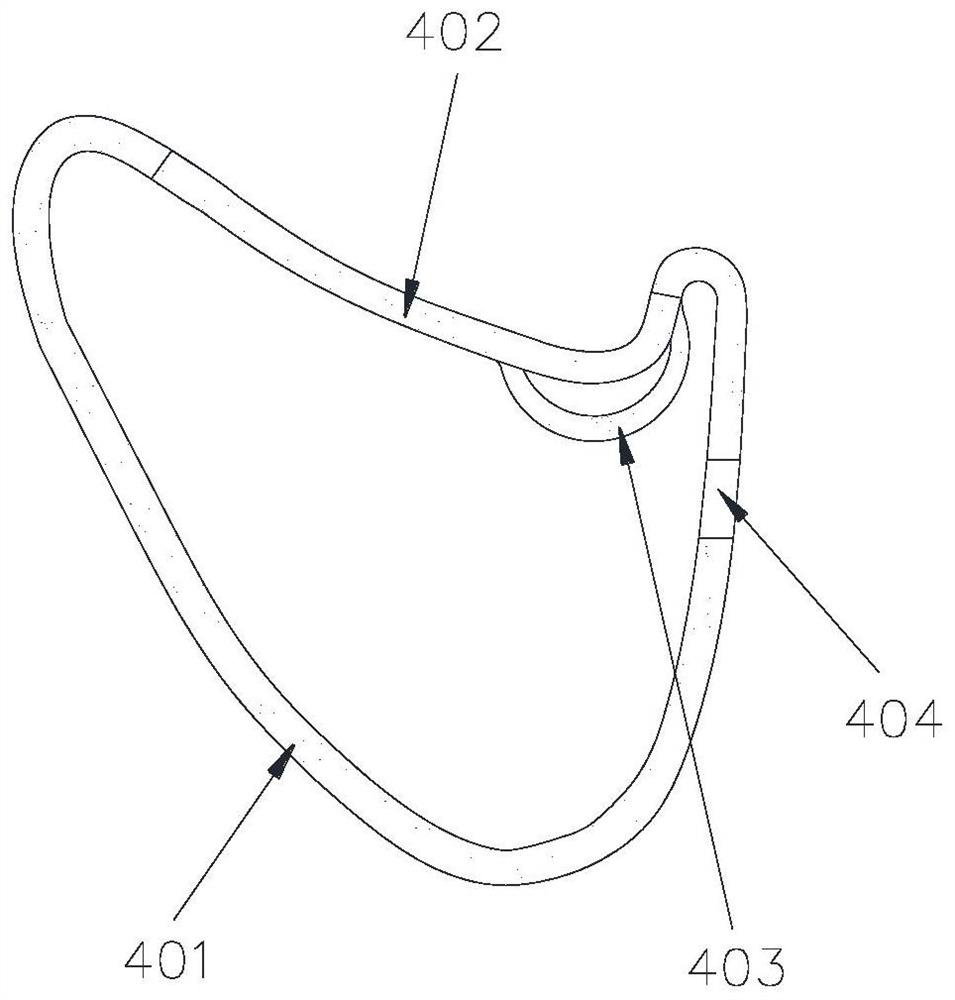

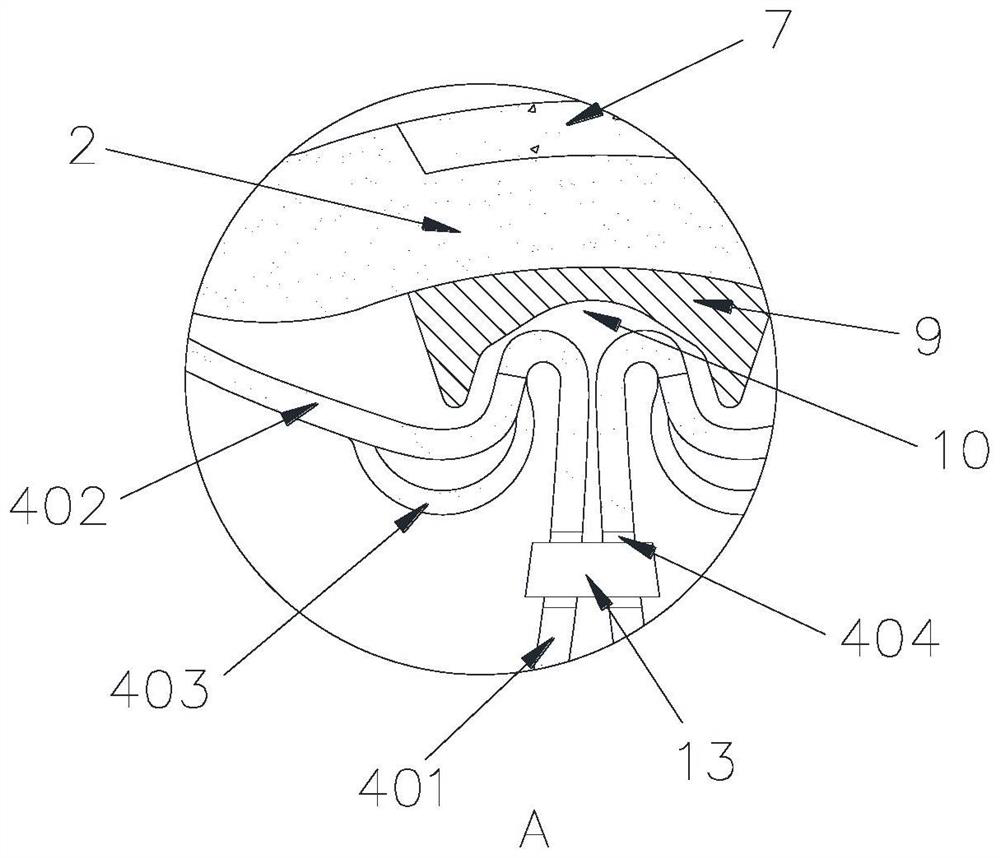

[0024] refer to figure 1 , image 3 , Figure 4 and Image 6 , an automobile sealing strip assembly with self-compression function, comprising an elastic sealing strip body 2, the interior of the sealing strip body 2 is a hollow structure, and two sets of curved support frames 4 are symmetrically arranged inside the sealing strip body 2, The support frame 4 has elasticity, the two ends of the support frame 4 are raised upward, a jacking block 9 is provided on the inner top of the sealing strip body 2, and the bottom surface of the jacking block 9 is provided with an upwardly concave guide surface 10, so that the jacking block is The top surface of 9 is high in the middle and low on both sides, and a first raised portion 5 and a second raised portion 6 are respectively provided on both sides of the top of the weather strip body 2, and between the first raised portion 5 and the second raised portion 6 A third raised portion 7 is provided, and the jacking block 9 is located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com