Method for testing adhesive property of asphalt and aggregate interface transition area in core wall dam

A technology for interfacial transition zone and bonding performance, which is applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of low accuracy of test results and difficult sampling, and achieve the effect of improving the performance evaluation system and fast bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] An asphalt concrete core wall dam is located in Gansu, using quartzite aggregate as asphalt concrete aggregate (lithology is neutral), and the asphalt is Karamay No. 70 asphalt;

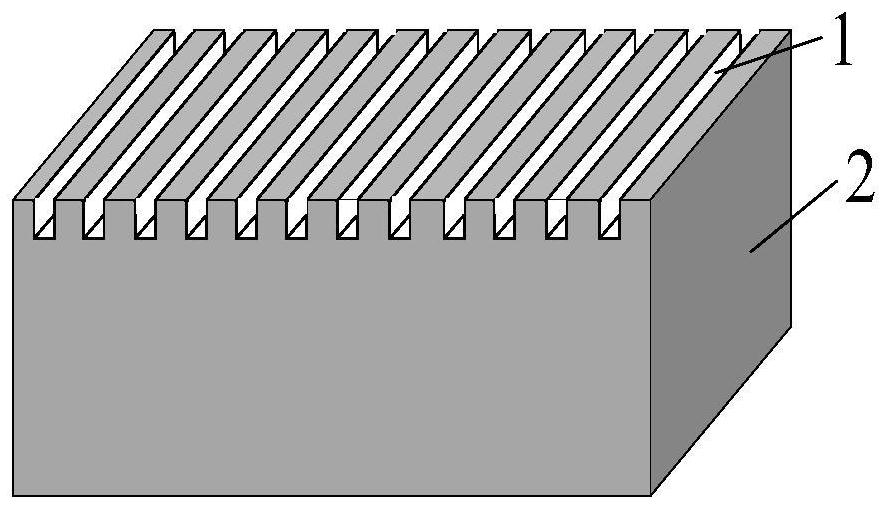

[0074] Eight cuboid stones with a size of 100*100*50mm were made after grooving, and the roughness of the cuboid stones after grooving were 1.02, 1.04, 1.06, 1.08, 1.10, 1.12, 1.14, 1.16;

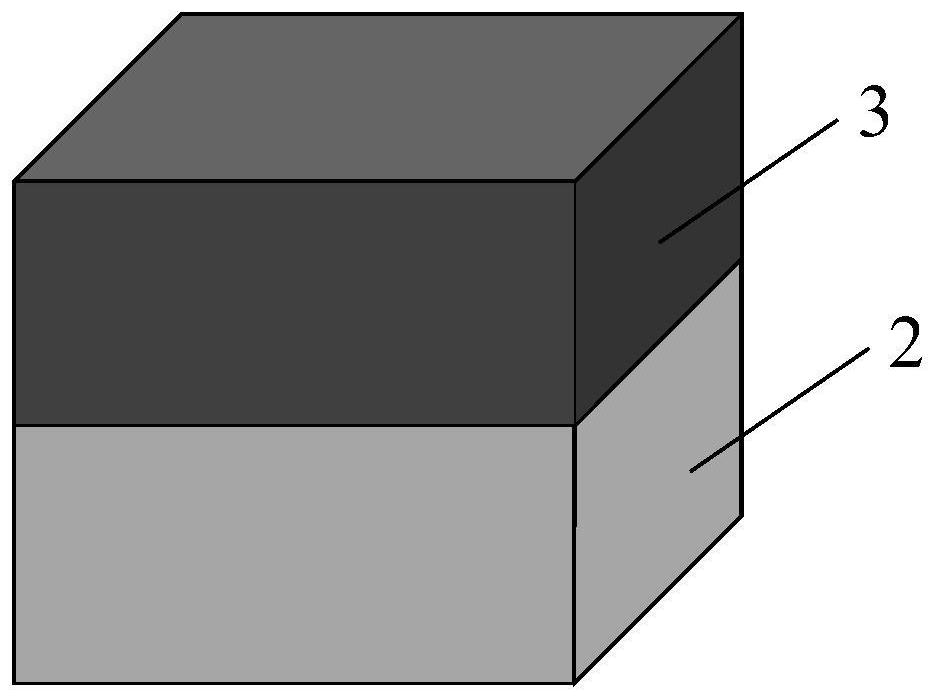

[0075] Put the cuboid stone after grooving into a 100*100*100mm steel mold, with the groove facing up, pour the dissolved asphalt above the cuboid stone after grooving to form a 100*100*100mm composite specimen , placed at room temperature for 24 hours, and after the asphalt was completely cooled, demolded to obtain 8 cube composite specimens;

[0076] Put 8 cube composite specimens into the direct shearing instrument respectively, and carry out the shearing test. Under the condition of the ambient temperature of -10~10 °C, the shearing speed of the loading system in the direct shearing instrument is set to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com