Simulation experiment set for filling pipeline wear

A technology for simulating experimental devices and filling tubes, which is applied in the direction of testing wear resistance, etc., which can solve the problems of difficult refueling, large filling materials, and large equipment, and achieve the effects of low experimental cost, small footprint, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

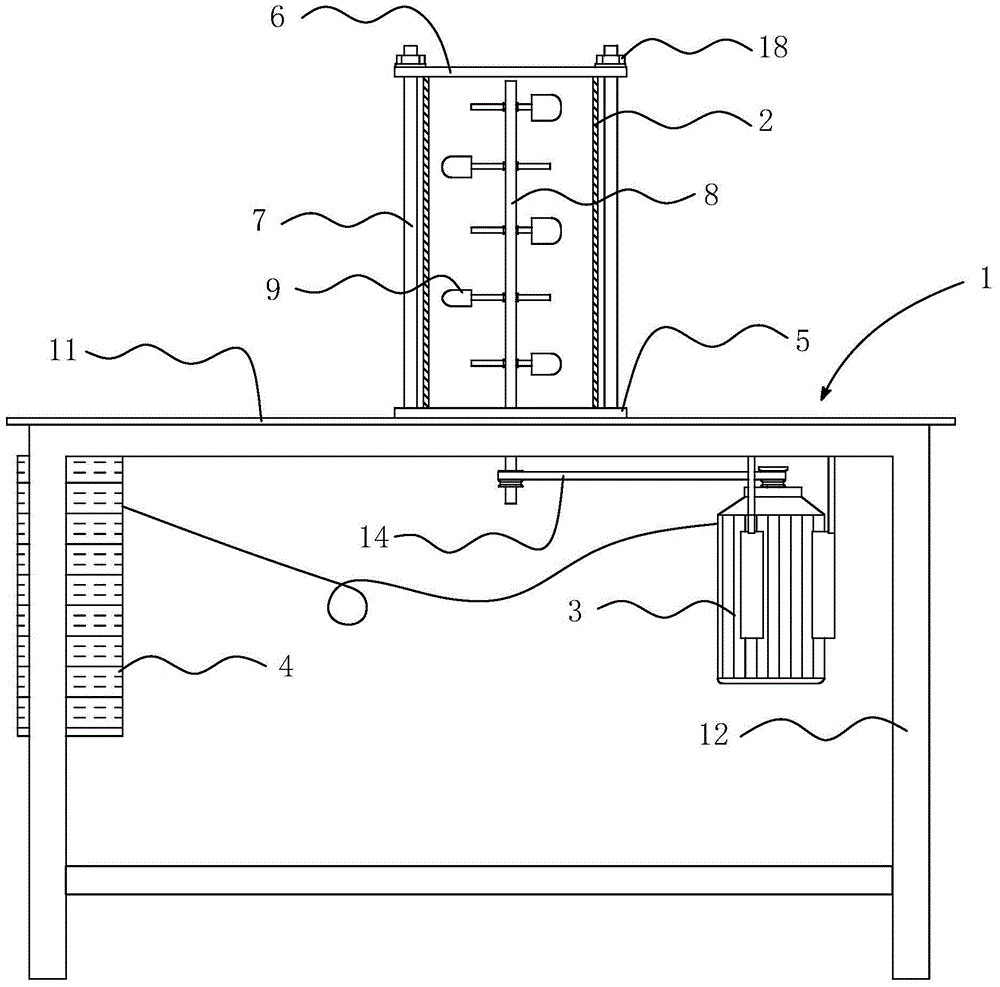

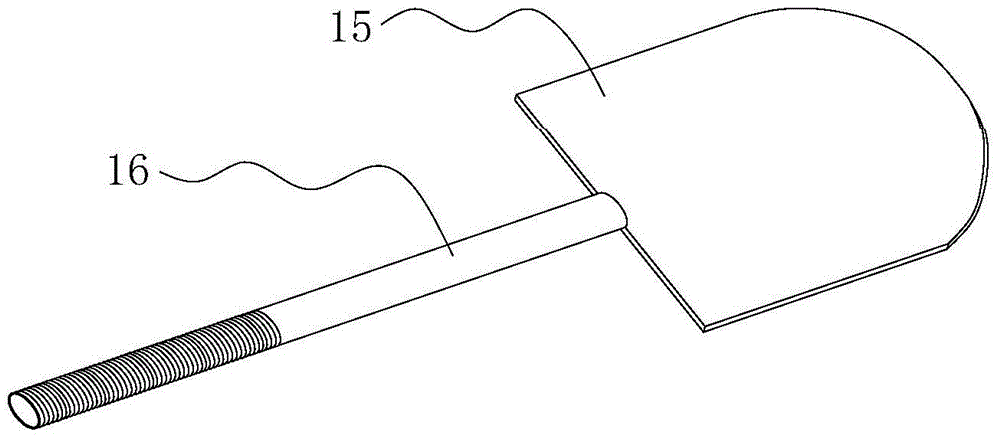

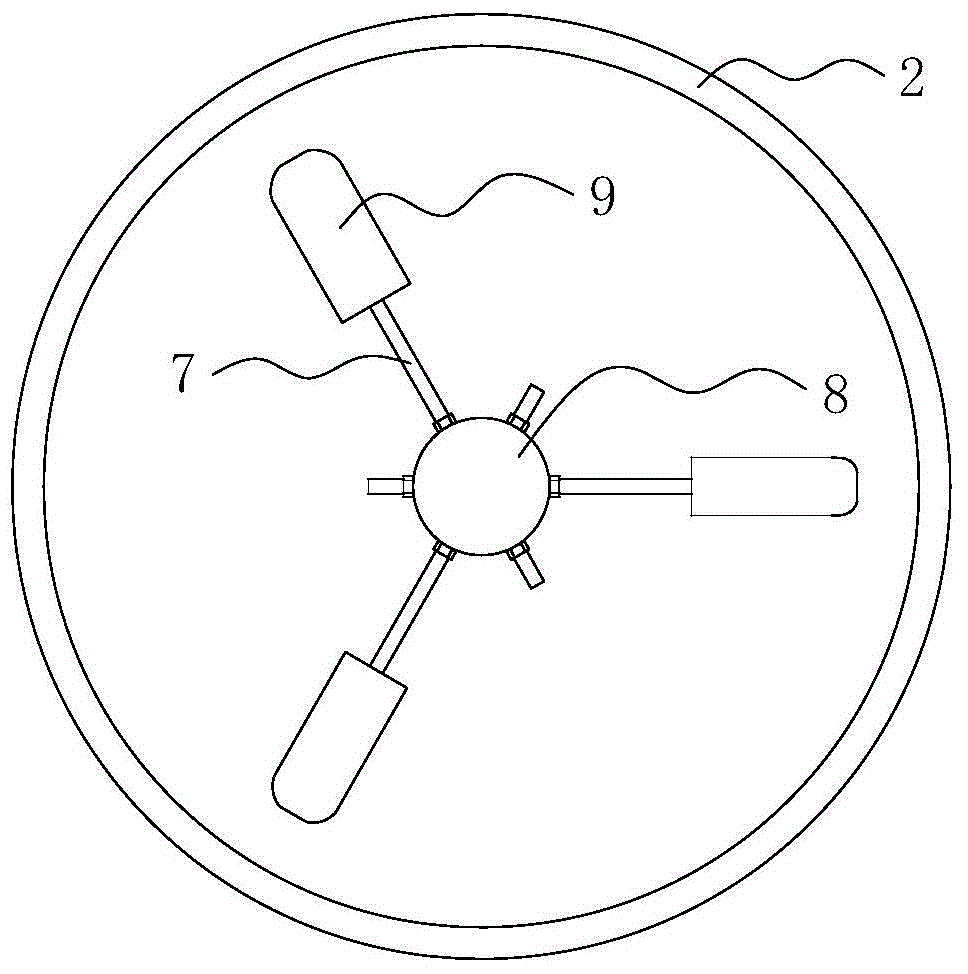

[0020] combine Figure 1 to Figure 5 , is a simulation experiment device for the wear of filling pipelines used in coal mines, including a workbench 1, a filling pipe 2, a motor 3 and a frequency conversion speed controller 4, the workbench 1 includes a table 11 and a support frame 12, and the support below the table 11 The frame 12 is provided with a motor 3, and the frequency converter 4 is arranged under the table top 11; the bottom sealing plate 5 is fixed on the table top 11, and an assembly hole 13 is opened in the middle of the bottom sealing plate 5, and the assembly hole 13 runs through The table top 11, the upper surface of the lower sealing plate 5 is provided with a vertical filling pipe 2, and the upper end of the filling pipe 2 is equipped with an upper cover plate 6, and the upper cover plate 6 and the lower sealing plate 5 pass through a vertical tie rod outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com