Wood door surface polishing equipment

A surface polishing and equipment technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve the problems of poor polishing effect of equipment and different glossiness of patterns on the surface of wooden doors, so as to improve the polishing effect, same gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

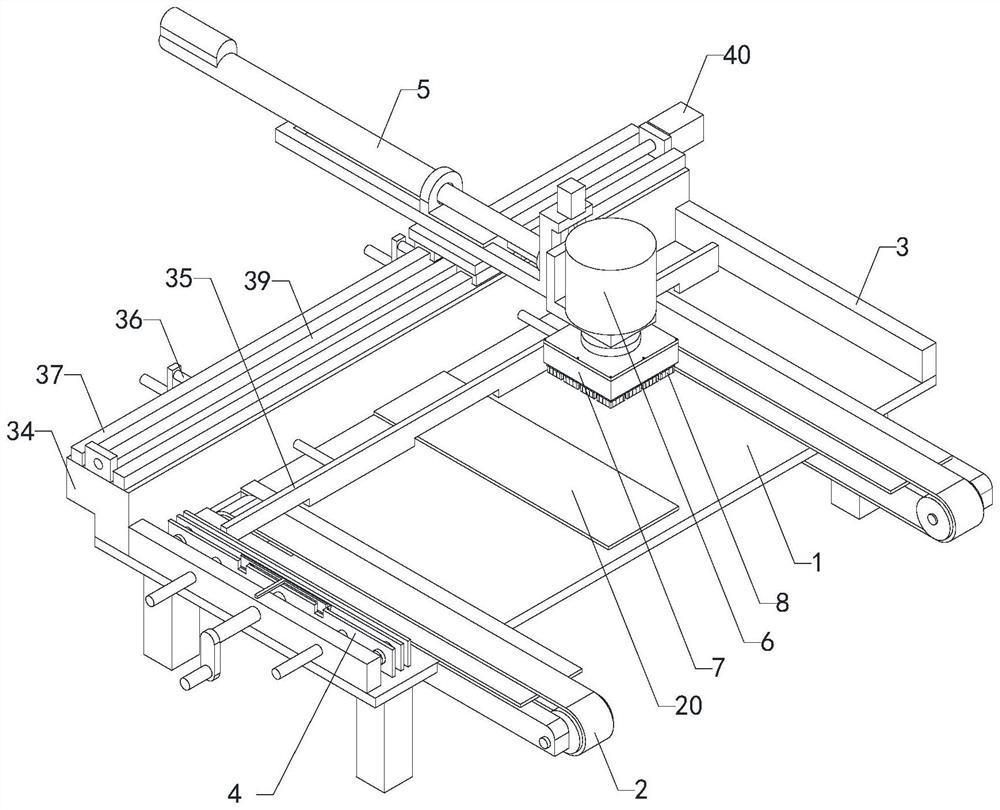

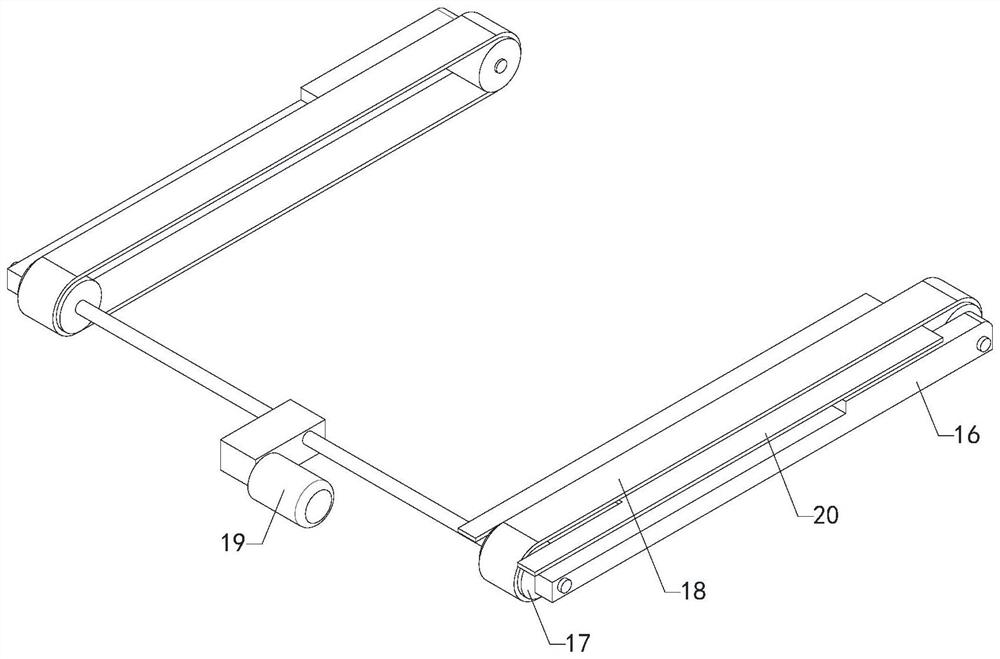

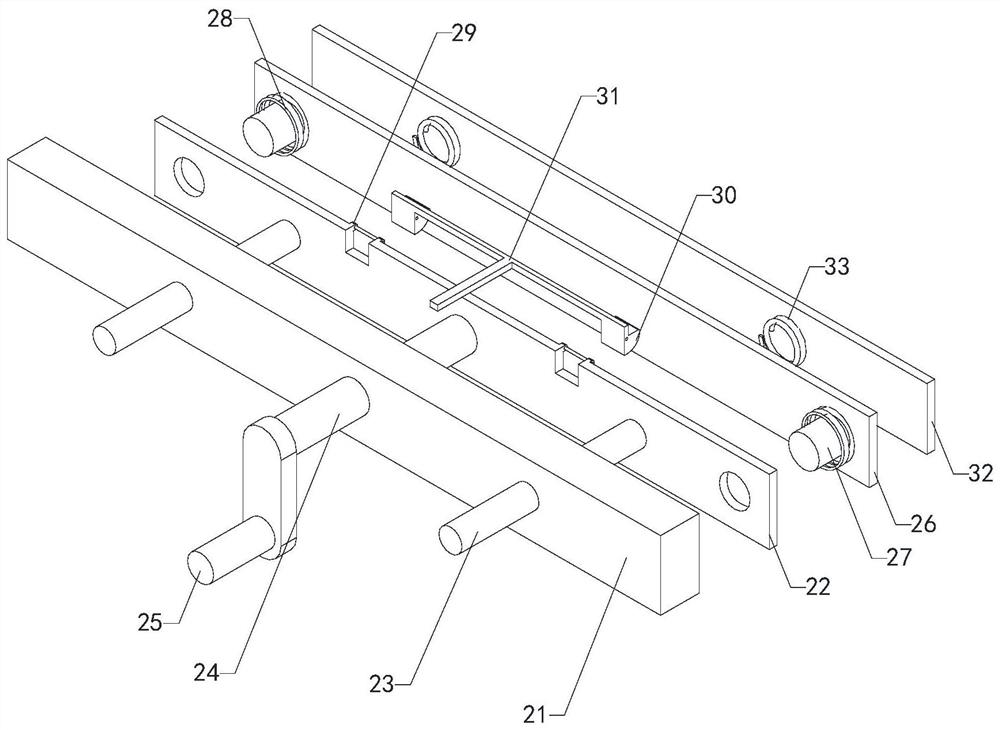

[0022]A wooden door surface polishing equipment, comprising a platform 1, a conveying mechanism 2, a right backing plate 3, a clamping mechanism 4, a driving mechanism 5, a polishing mechanism 6, a polishing box 7 and a plurality of polishing units 8, and the upper end surface of the platform 1 is installed. There is a conveying mechanism 2, the conveying mechanism 2 extends out of the front side of the platform 1, the right backing plate 3 is installed on the right end of the upper end surface of the platform 1, the clamping mechanism 4 is installed on the left end of the upper end surface of the platform 1, and the driving mechanism 5 is installed on the platform 1. At the rear end of the upper end face of the upper end face of the upper end, the polishing mechanism 6 is installed on the driving mechanism 5, the polishing mechanism 6 is located on the upper end face of the platform 1, the polishing box 7 is concentrically installed on the output end of the polishing mechanism ...

Embodiment 2

[0024] A wooden door surface polishing equipment, comprising a platform 1, a conveying mechanism 2, a right backing plate 3, a clamping mechanism 4, a driving mechanism 5, a polishing mechanism 6, a polishing box 7 and a plurality of polishing units 8, and the upper end surface of the platform 1 is installed. There is a conveying mechanism 2, the conveying mechanism 2 extends out of the front side of the platform 1, the right backing plate 3 is installed on the right end of the upper end surface of the platform 1, the clamping mechanism 4 is installed on the left end of the upper end surface of the platform 1, and the driving mechanism 5 is installed on the platform 1. At the rear end of the upper end face of the upper end face of the upper end, the polishing mechanism 6 is installed on the driving mechanism 5, the polishing mechanism 6 is located on the upper end face of the platform 1, the polishing box 7 is concentrically installed on the output end of the polishing mechanism...

Embodiment 3

[0026] A wooden door surface polishing equipment, comprising a platform 1, a conveying mechanism 2, a right backing plate 3, a clamping mechanism 4, a driving mechanism 5, a polishing mechanism 6, a polishing box 7 and a plurality of polishing units 8, and the upper end surface of the platform 1 is installed. There is a conveying mechanism 2, the conveying mechanism 2 extends out of the front side of the platform 1, the right backing plate 3 is installed on the right end of the upper end surface of the platform 1, the clamping mechanism 4 is installed on the left end of the upper end surface of the platform 1, and the driving mechanism 5 is installed on the platform 1. At the rear end of the upper end face of the upper end face of the upper end, the polishing mechanism 6 is installed on the driving mechanism 5, the polishing mechanism 6 is located on the upper end face of the platform 1, the polishing box 7 is concentrically installed on the output end of the polishing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com