Method for altering color of white coral by laser

A coral and laser technology, used in special decorative structures, decorative arts, clothing, etc., can solve the problems of cumbersome dyeing process, easy to fall off, and cannot be stored for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Cut the white coral into thin slices with a thickness of 1mm with a crystal cutter, and then clean the surface with an ultrasonic cleaner;

[0023] Place the white coral sample on the rotating platform, and use the laser as the heat source for irradiation preheating. The single-sided scanning irradiation method is adopted. The laser spot area covers the entire surface of the white coral sample. The rotation speed of the rotating platform is 24rad / min. The warm-up time is 60s, and the power density of the laser is 9w / cm 2 ;

[0024] After preheating, increase the power density of the laser to 16w / cm 2 After continuing to irradiate for 120s, turn off the laser light source, cool to room temperature in the air, and process a light brown-red coral sample.

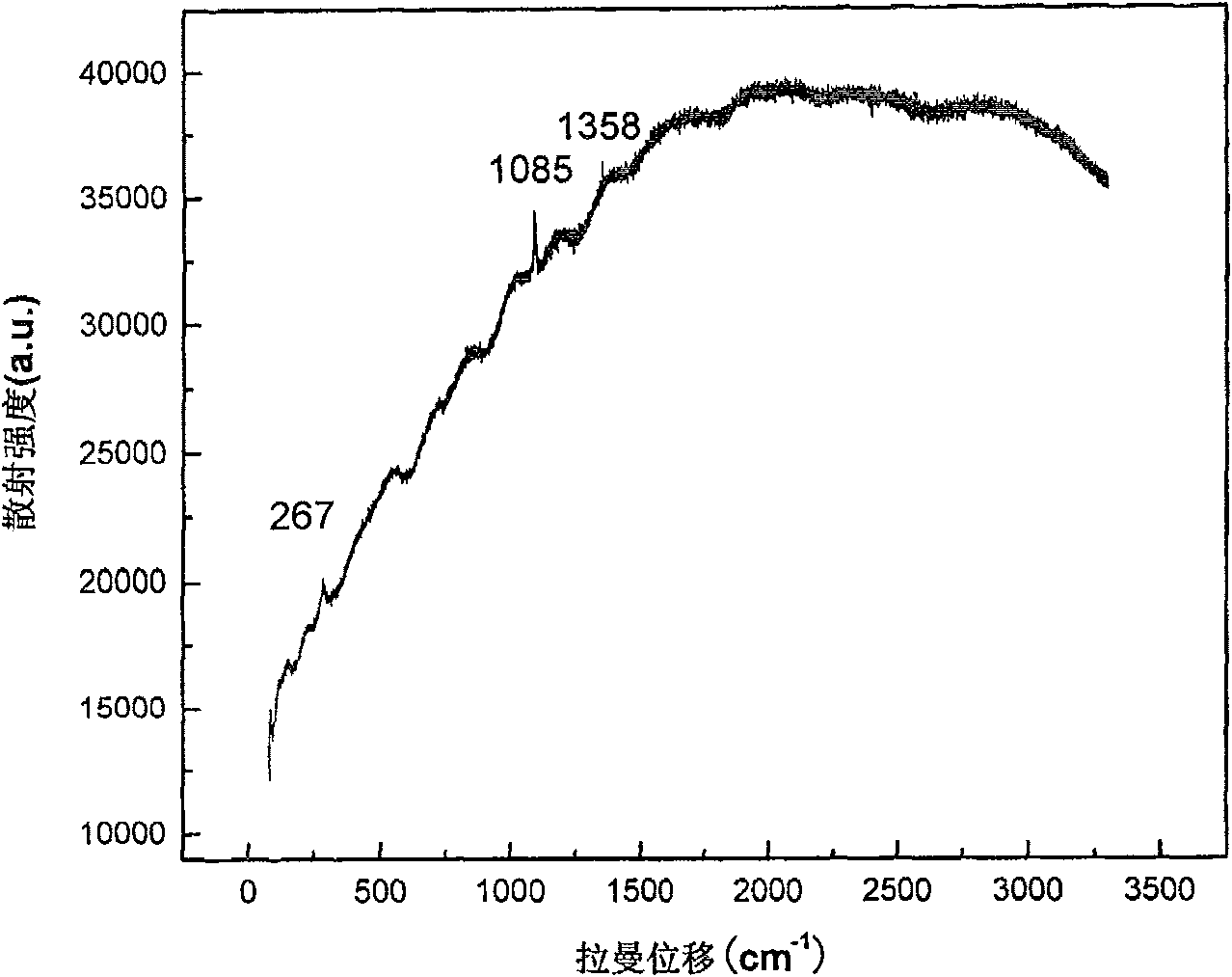

[0025] It can be seen from Figure 1 that the characteristic peaks of the Raman spectrum of white coral before laser irradiation (figure b) almost completely correspond to the Raman spectrum of calcite minerals; white c...

Embodiment 2

[0027] Cut the white coral into thin slices with a thickness of 1.5mm with a crystal cutter, and then clean the surface with an ultrasonic cleaner;

[0028] Put the white coral sample on the rotating platform, and use the laser as the heat source for irradiation preheating. The irradiation adopts a single-sided scanning irradiation method. The laser spot area covers the entire surface of the white coral sample. The rotation speed of the rotating platform is 24rad / min. The irradiation preheating time is 40s, and the laser power density is 10w / cm 2 ;

[0029] After preheating, increase the power density of the laser to 18w / cm 2 After continuing to irradiate for 60 s, turn off the laser light source, cool to room temperature in the air, and process a light brown-red coral sample.

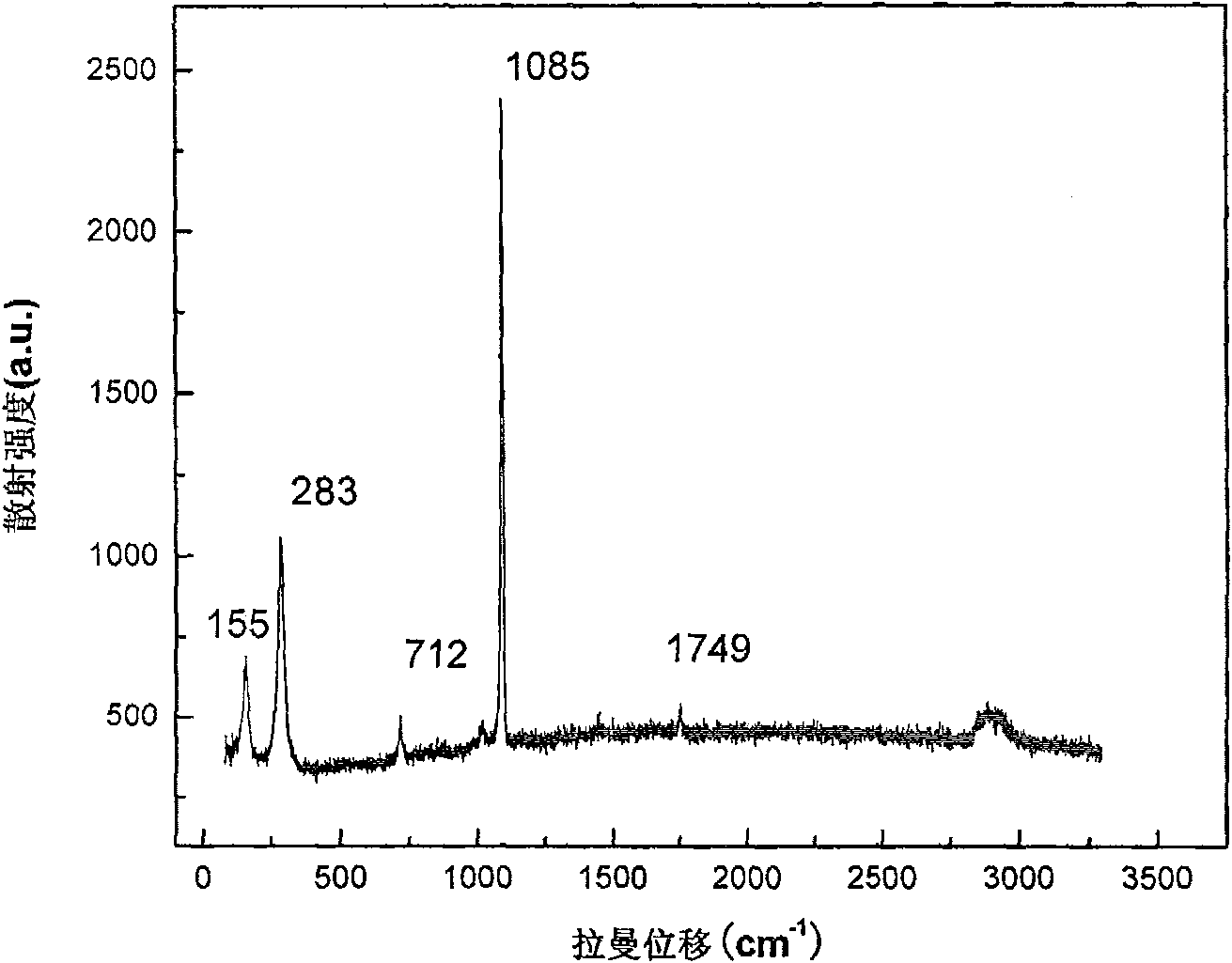

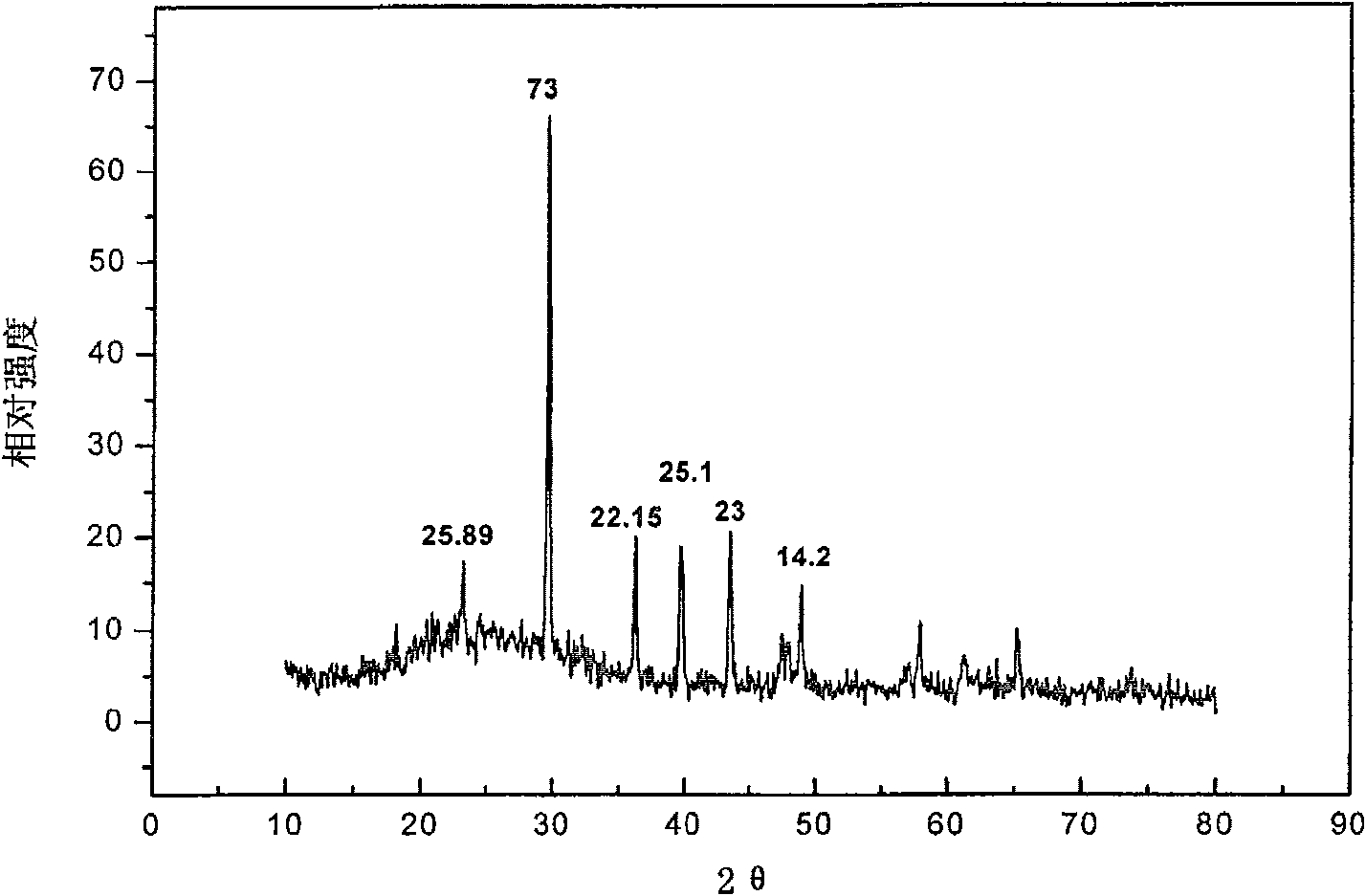

[0030] It can be seen from Figure 2 that the change of Raman spectrum reflects the structural change inside the coral, which leads to the change of diffraction. As shown in the X-ray diffraction dia...

Embodiment 3

[0032] Cut the white coral into thin slices with a thickness of 2mm with a crystal cutter, and then clean the surface with an ultrasonic cleaner;

[0033] Put the white coral sample on the rotating platform, and use the laser as the heat source for irradiation preheating. The irradiation adopts a single-sided scanning irradiation method. The laser spot area covers the entire surface of the white coral sample. The rotation speed of the rotating platform is 24rad / min. The irradiation warm-up time is 45s, and the laser power density is 8w / cm 2 ;

[0034] After preheating, increase the power density of the laser to 17w / cm 2 After continuing to irradiate for 60 s, turn off the laser light source, cool to room temperature in the air, and process a light brown-red coral sample.

[0035] It can be seen from Figure 3 that the surface morphology of white coral after laser irradiation shows that the surface quality is improved, there is no microstructural damage such as particle impuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com