Hanging structure of split type assembly type suspended ceiling

A prefabricated and split-type technology, applied in ceilings, building components, building structures, etc., can solve the problems of high cost of components, unfavorable installation, inability to simplify the ceiling structure, etc., and achieve the effect of simplifying installation efficiency and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

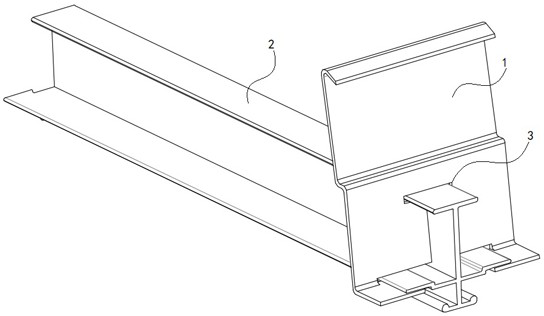

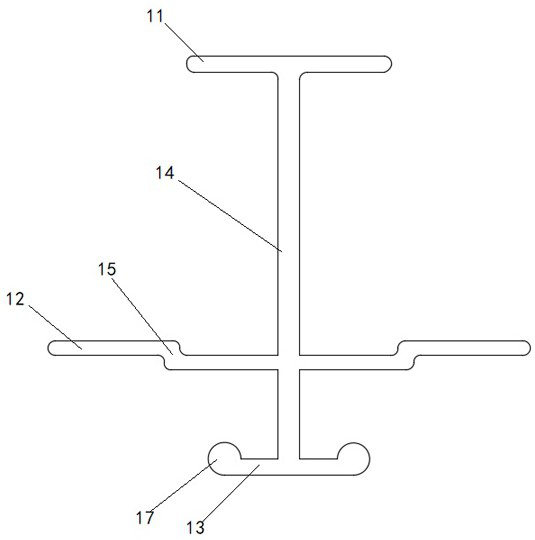

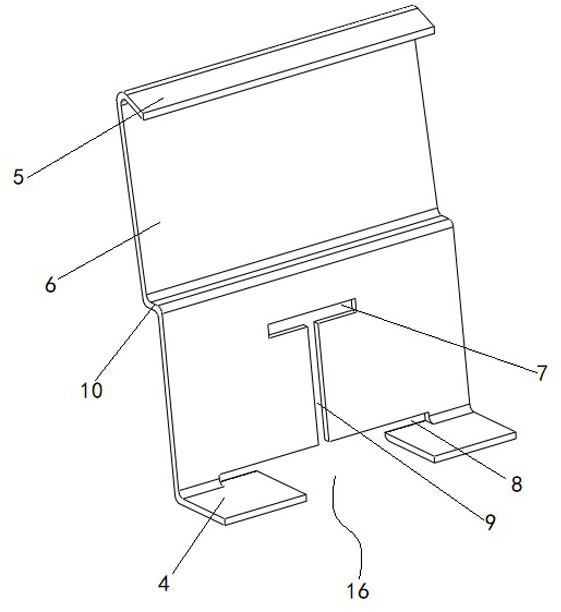

[0022] A hooking structure of a split-type assembled ceiling, comprising a hooking piece 1 and an I-shaped piece 2, a hooking slot 3 is formed on the end surface of the hanging piece 1, and the I-shaped piece 2 is inserted into the hooking slot 3. The bottom of the character piece 2 is bent and formed with a support plate 4, and the support plate 4 cooperates with the hooking groove 3 to hang the I-shaped piece 2. During installation, the I-shaped piece 2 is directly inserted into the hanging piece 2, and then The attachment piece 1 is attached to the keel, and it is convenient to disassemble and assemble, which greatly simplifies the installation efficiency of the I-shaped piece 2 .

[0023] The upper end face of the support plate 4 is attached to the middle horizontal plate of the I-shaped piece 2, on the one hand, it can provide a certain lifting force for the I-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com