Salt spray corrosion test box

A technology for salt spray corrosion and test chambers, which is applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc. It can solve problems that affect the accuracy of experimental results, uneven spraying of items to be tested, etc., and reduce salt spray damage , improve accuracy, and spray evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is combined with the attached Figure 1-7 Further elaboration of this application.

[0035] Embodiments of the present application disclose a salt spray corrosion test chamber.

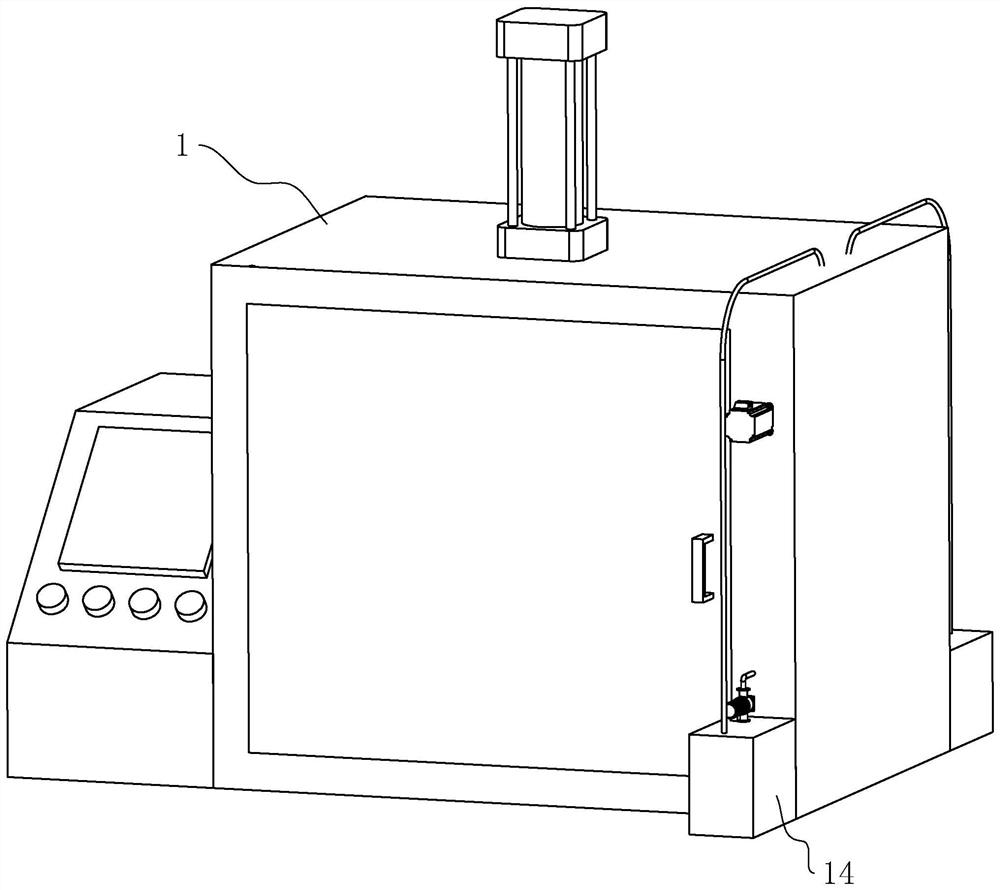

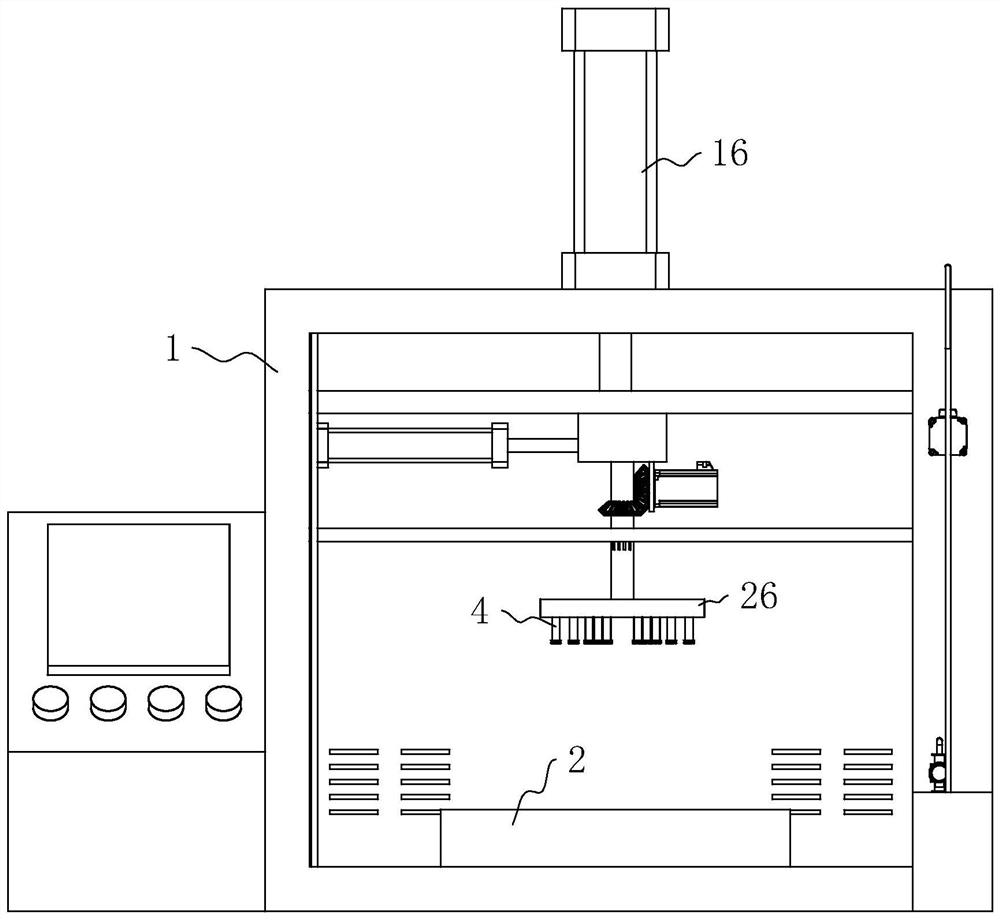

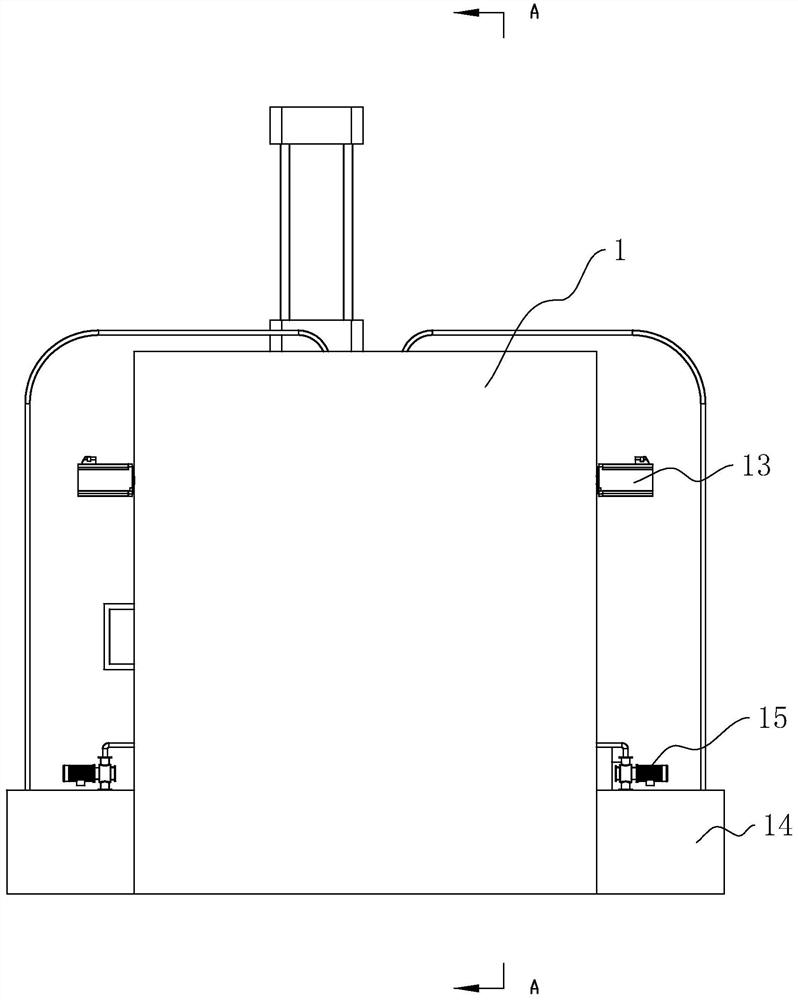

[0036] Reference Figure 1 and Figure 2 The salt spray corrosion test chamber comprises a box 1, a placement table 2 disposed in the box 1, a salt spray box, a sprinkler head 4, and a pipeline connected to the salt spray chamber and the sprinkler 4. Wherein, the box 1 is provided with a temperature regulation device, turntable 26, the nozzle 4 is fixed on the turntable 26, the box 1 is provided with a drive mechanism for adjusting the height of the turntable 26, a drive mechanism for adjusting the horizontal position of the turntable 26 and a drive mechanism for driving the turntable 26 rotation three.

[0037] Reference Figure 2 、 Figure 3 and Figure 4 , the temperature regulation device comprises a mounting cylinder 5, fixed to the mounting cylinder 5 on the heating wire 6, fixed to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap