An automatic power-off device for charging a new energy electric vehicle

An automatic power-off, electric vehicle technology, applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of fire, line short circuit, high temperature, and achieve the effect of preventing continuous influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

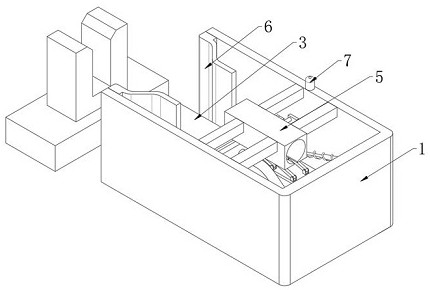

Image

Examples

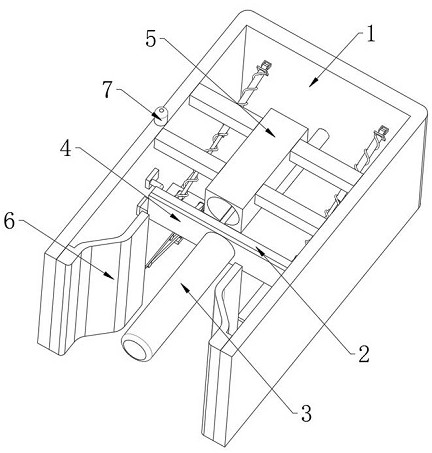

Embodiment 1

[0035] In one of the more preferred embodiments, the disengagement mechanism includes a carrier plate 11 installed at the bottom of the wiring seat 2, the inner wall of the recessed seat 1 is fixedly mounted with a support plate 12 parallel to the carrier plate 11, and the top of the support plate 12 is connected to the bearing plate 11. A plurality of connecting rods 13 are hinged between the bottom of the plate 11, and a telescopic rod 14 is hinged between the outer wall of the bearing plate 11 away from the terminal 3 and the inner wall of the indented seat 1, and spring seats are installed at both ends of the telescopic rod 14. A tension spring 15 is fixedly installed between the two spring bases. In the state of contact and energization, the thermal trigger assembly limits the terminal base 2 and makes the tension spring 15 in a deformed and stretched state.

[0036] like Figure 5 As shown in the figure, a parallelogram structure is formed between the bearing plate 11 , ...

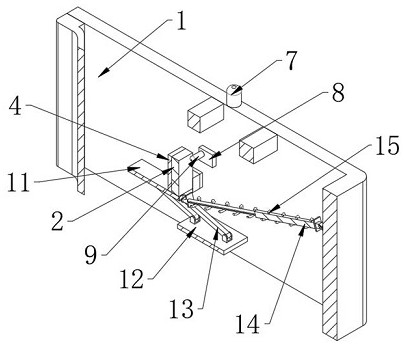

Embodiment 2

[0048] In another preferred embodiment, the disengagement mechanism is installed on the rotating shafts 18 on the outer walls of both sides of the terminal block 2. The rotating shafts 18 are all rotatably connected to the inner wall of the indented base 1, and the rotation of the torsion spring 19 can make the terminal 3 separate from the terminal block. , the outer wall of one of the rotating shafts 18 is sleeved with a torsion spring 19, and the two ends of the torsion spring 19 are respectively fixedly connected with the inner wall of the indented seat 1 and the outer wall of the wiring seat 2. In the state of contacting with electricity, the thermal trigger assembly will connect the wiring The seat 2 limits the position and causes the torsion spring 19 to twist and accumulate deformation potential energy.

[0049] like Figure 8 and Figure 9 As shown in the figure, by rotating the terminal block 2, the torsion spring 19 will be twisted to accumulate the deformation pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com