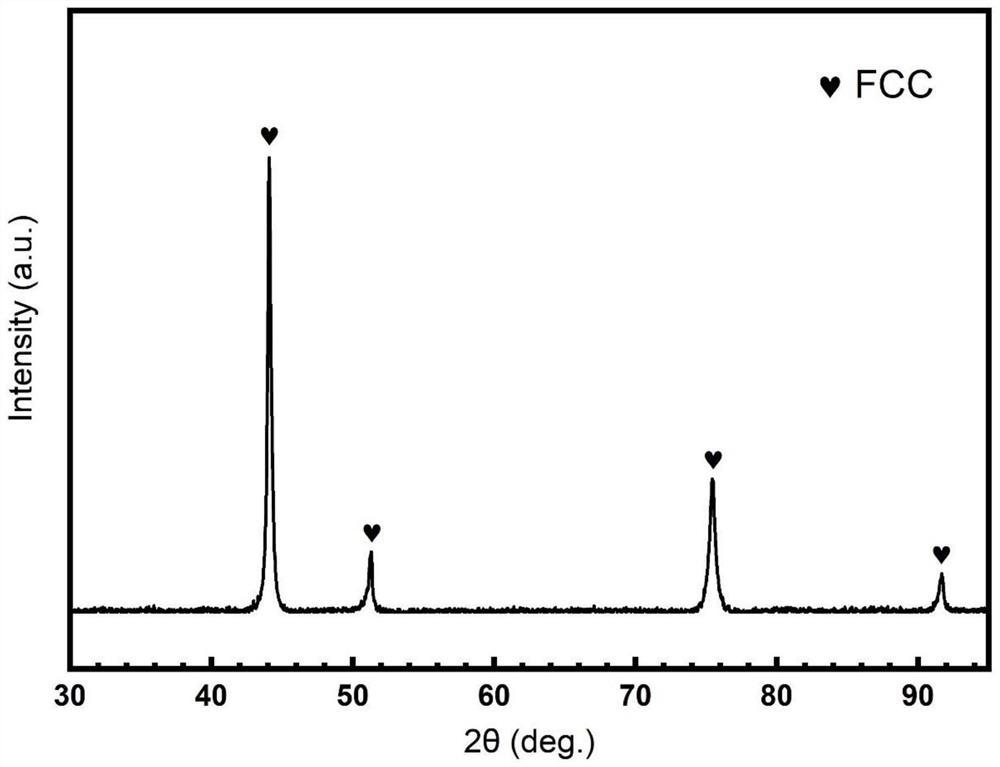

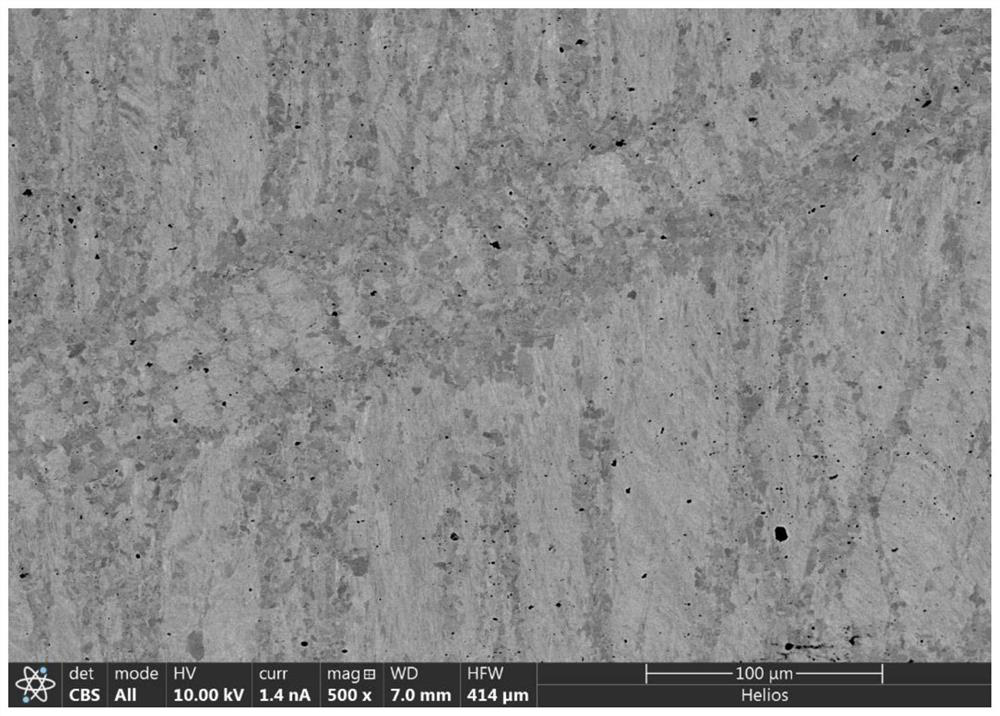

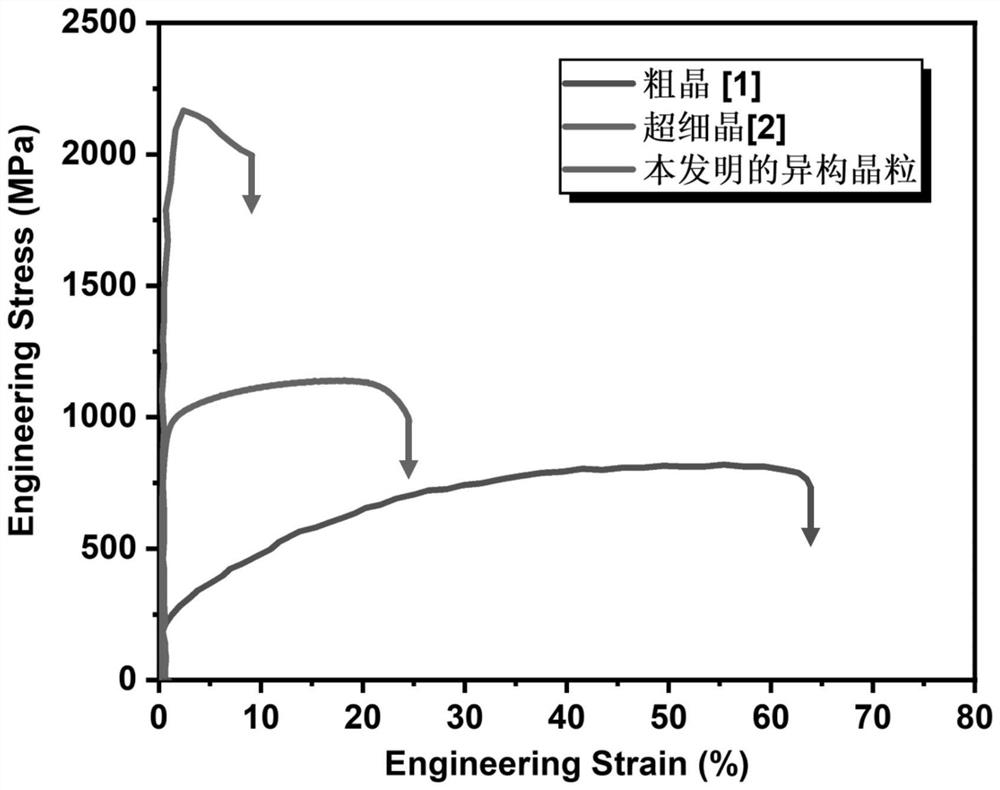

Low-temperature-wear-resistant medium-entropy alloy and preparation method thereof

A technology of entropy alloy and low temperature resistance, which achieves the effects of overcoming brittle spalling, high production efficiency, improving mechanical properties and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of a low-temperature wear-resistant medium-entropy alloy, comprising the following steps:

[0038]S1. Ingredients and surface treatment of raw materials: according to the atomic ratio of 1:1:1, weigh 15.33g of high-purity Cr, 17.37g of high-purity Co, and 17.30g of high-purity Ni, and use sandpaper or a grinder to clean the surface of the single substance Grind to remove scale and impurities, then use absolute ethanol to sonicate the simple substances of each element for 20-30 minutes, dry them with a hair dryer, and mix them for use.

[0039] S2. Alloy smelting and suction casting: Put the prepared Co, Cr, and Ni elements into the copper mold crucible of the vacuum arc melting furnace, and put a Ti ingot in the furnace at the same time, and use the mechanical pump and the molecular pump to evacuate to The vacuum degree in the chamber reaches 0.5~1×10 -4 MPa, fill the chamber with high-purity Ar gas to 0.05-0.08MPa, and use a high-frequency DC powe...

Embodiment 1

[0047] Example 1:

[0048] A preparation method of a low-temperature wear-resistant medium-entropy alloy, comprising the following steps:

[0049] S1. Ingredients and surface treatment of raw materials: according to the atomic ratio of 1:1:1, weigh 15.33g of high-purity Cr, 17.37g of high-purity Co, and 17.30g of high-purity Ni, and use sandpaper or a grinder to clean the surface of the single substance Grinding was carried out to remove scale and impurities, and then each element was ultrasonicated for 30 minutes with absolute ethanol, dried with a hair dryer, and mixed for use.

[0050] S2. Alloy smelting and suction casting: Put the prepared Co, Cr, and Ni elements into the copper mold crucible of the vacuum arc melting furnace, and put a Ti ingot in the furnace at the same time, and use the mechanical pump and the molecular pump to evacuate to The vacuum degree in the chamber reaches 1×10 - 4 MPa, fill the chamber with high-purity Ar gas to 0.05MPa, and use a high-frequ...

Embodiment 2

[0053] Example 2:

[0054] A preparation method of a low-temperature wear-resistant medium-entropy alloy, comprising the following steps:

[0055] S1. Ingredients and surface treatment of raw materials: according to the atomic ratio of 1:1:1, weigh 15.33g of high-purity Cr, 17.37g of high-purity Co, and 17.30g of high-purity Ni, and use sandpaper or a grinder to clean the surface of the single substance Grinding was carried out to remove scale and impurities, and then each element was ultrasonicated for 30 minutes with absolute ethanol, dried with a hair dryer, and mixed for use.

[0056] S2. Alloy smelting and suction casting: Put the prepared Co, Cr, and Ni elements into the copper mold crucible of the vacuum arc melting furnace, and put a Ti ingot in the furnace at the same time, and use the mechanical pump and the molecular pump to evacuate to The vacuum degree in the chamber reaches 1×10 - 4 MPa, fill the chamber with high-purity Ar gas to 0.05MPa, and use a high-frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com