Pipeline socket type butt joint installation method based on rubber rings

A technology of butt joint installation and rubber ring, which is applied in the direction of sleeve/socket connection, pipe laying and maintenance, pipe/pipe joint/pipe fitting, etc. Stable and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032]为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例,对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅仅用以解释本发明,并不用于限定本发明。

[0033]以下结合具体实施例对本发明的实现进行详细的描述。

[0034]本实施例的附图中相同或相似的标号对应相同或相似的部件;在本发明的描述中,需要理解的是,若有术语“上”、“下”、“左”、“右”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此附图中描述位置关系的用语仅用于示例性说明,不能理解为对本专利的限制,对于本领域的普通技术人员而言,可以根据具体情况理解上述术语的具体含义。

[0035]参照图1-5所示,为本发明提供的较佳实施例。

[0036]基于橡胶圈的管道承插式对接安装方法,包括以下安装步骤:

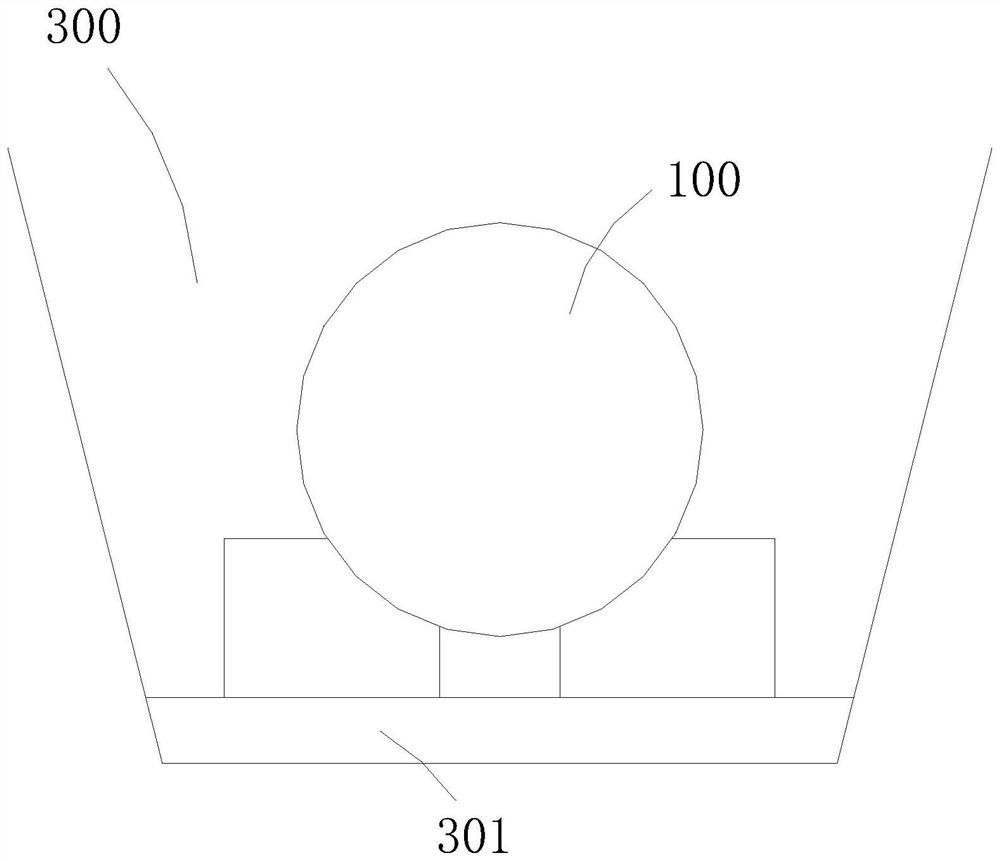

[0037]1)、检查沟槽300,并确认沟槽300满足设定要求;

[0038]2)、在沟槽300的底部设置垫层301,垫层301的强度满足设定要求,在垫层301上设置对中线;

[0039]3)、将待对接安装的管道100放置在沟槽300内,并使得管道100的中心线与对中线呈上下对齐,管道100具有对接端部,对接端部具有对接环槽,对接环槽沿着管道100的周向环绕布置;

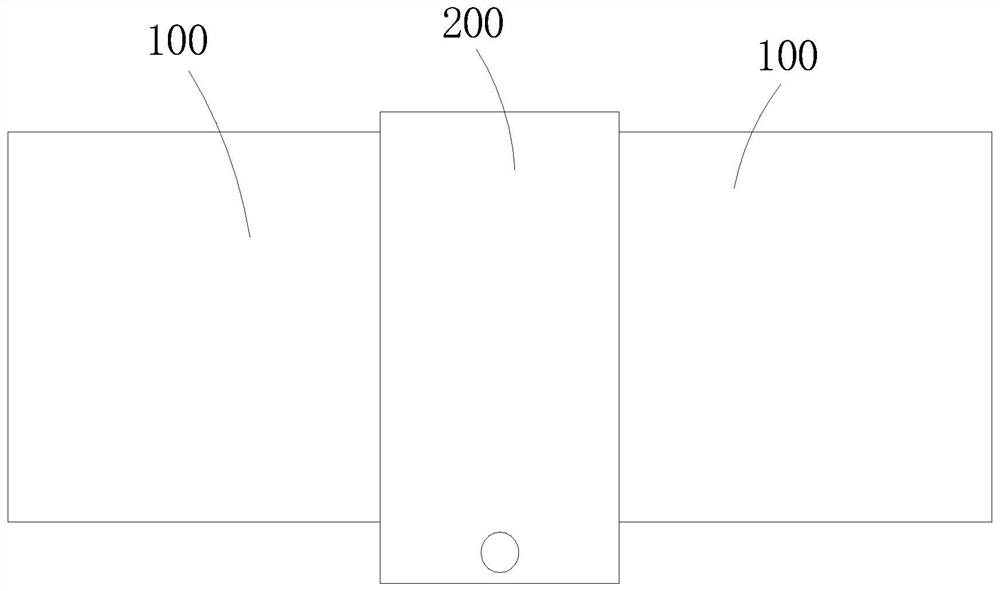

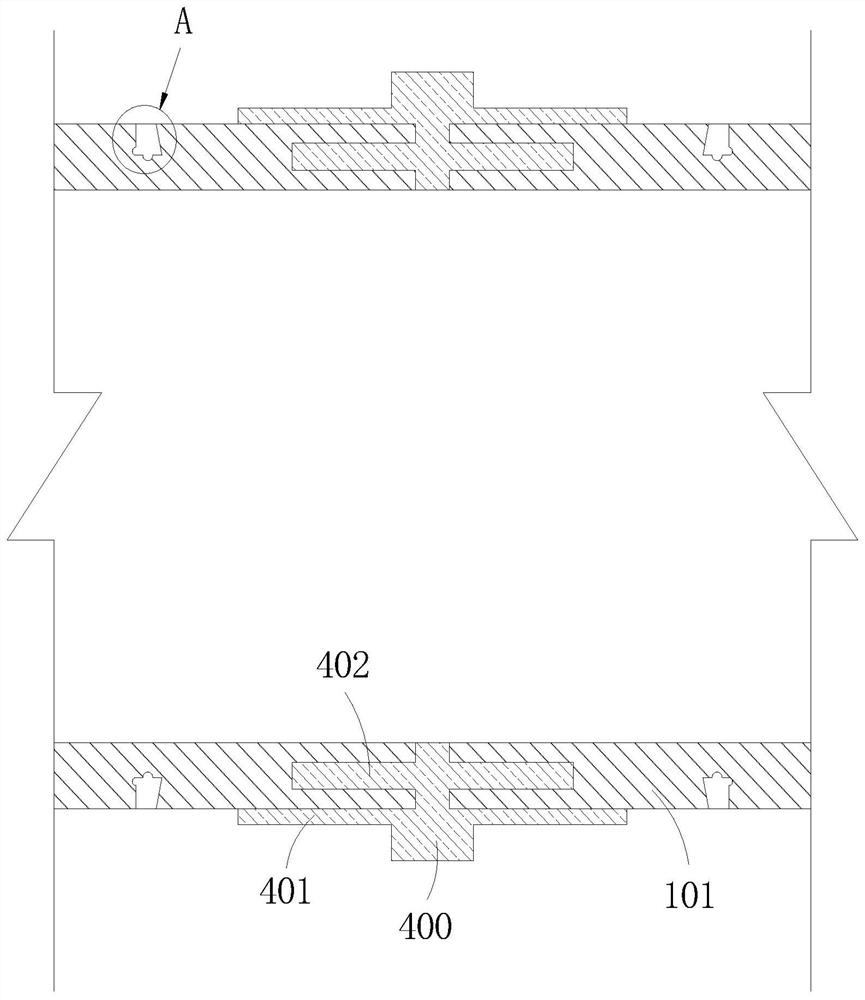

[0040]4)、布置橡胶圈400,橡胶圈400的两侧分别凸设有承插环条402以及外抵压环条401,外抵压环条401环绕在承插环条402的外周,且与承插环条402之间承插间隔;将橡胶圈400放置在两个管道100之间,承插环条402插入在对接环槽中,外抵压环条401抵压在管道100的外侧壁上,两个管道100的对接端部相向抵压着橡胶圈400;

[0041]在两个管道100的外部套设环状布置的紧节环200,紧节环200上设有调节紧节环200松紧程度的调节结构,紧节环200覆盖在橡胶圈400以及两个外抵压环条401上,通过调节所述调节结构,使得紧节环200的束紧力满足设定要求。

[0042]上述提供的基于橡胶圈的管道承插式对接安装方法,管道100放置在沟槽 300的垫层301上,通过对中线进行对中,两个管道100的对接端部相向抵压着橡胶圈400对接,通过橡胶圈400分别嵌入在两个对接端部的对接环槽中,实现两个管道100的对接端...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com