Copper pipe inner wall blow-drying device

A copper tube and cylinder wall technology, which is applied in the field of drying devices, can solve the problems of incomplete drying of water on the inner wall of the copper tube, affecting the processing of the copper tube, and weak butt joint, etc., and achieves simple structure, improved production efficiency, and firm butt joint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

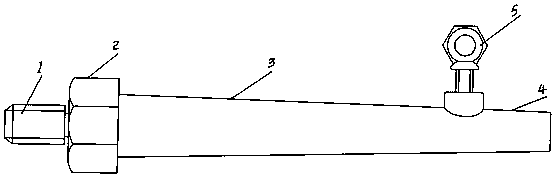

[0008] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 As shown, the rear end 1 of the blow-drying cylinder is processed with external threads, the front end of the blow-drying cylinder 3 is in the shape of a cone 4, and the wall of the front end of the vertical drying cylinder is equipped with a compression screw 5, and the blow-drying cylinder is hollow. The cylinder, the rear end of the drying cylinder is connected with the compression pump through the external thread and tightened by the nut 2, the cone at the front end of the drying cylinder is inserted into the copper pipe and tightened by the compression screw, and the compression screw 5 is vertical At the front end of the blow-drying cylinder, further, there is a hole in the wall of the drying cylinder, and a hex nut is welded on the hole. The jack screw is assembled in the nut and rotates downward to compress the cylinder wall. After the tapered mouth on the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com