Direction-changing interfacing dust suppression hoist

A hoist and hoisting tower technology, used in elevators, lifting equipment in mines, elevators in buildings, etc., can solve the problems of unguaranteed, low automation of battery powder, etc., to extend service life, save manpower, prevent Effects of damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

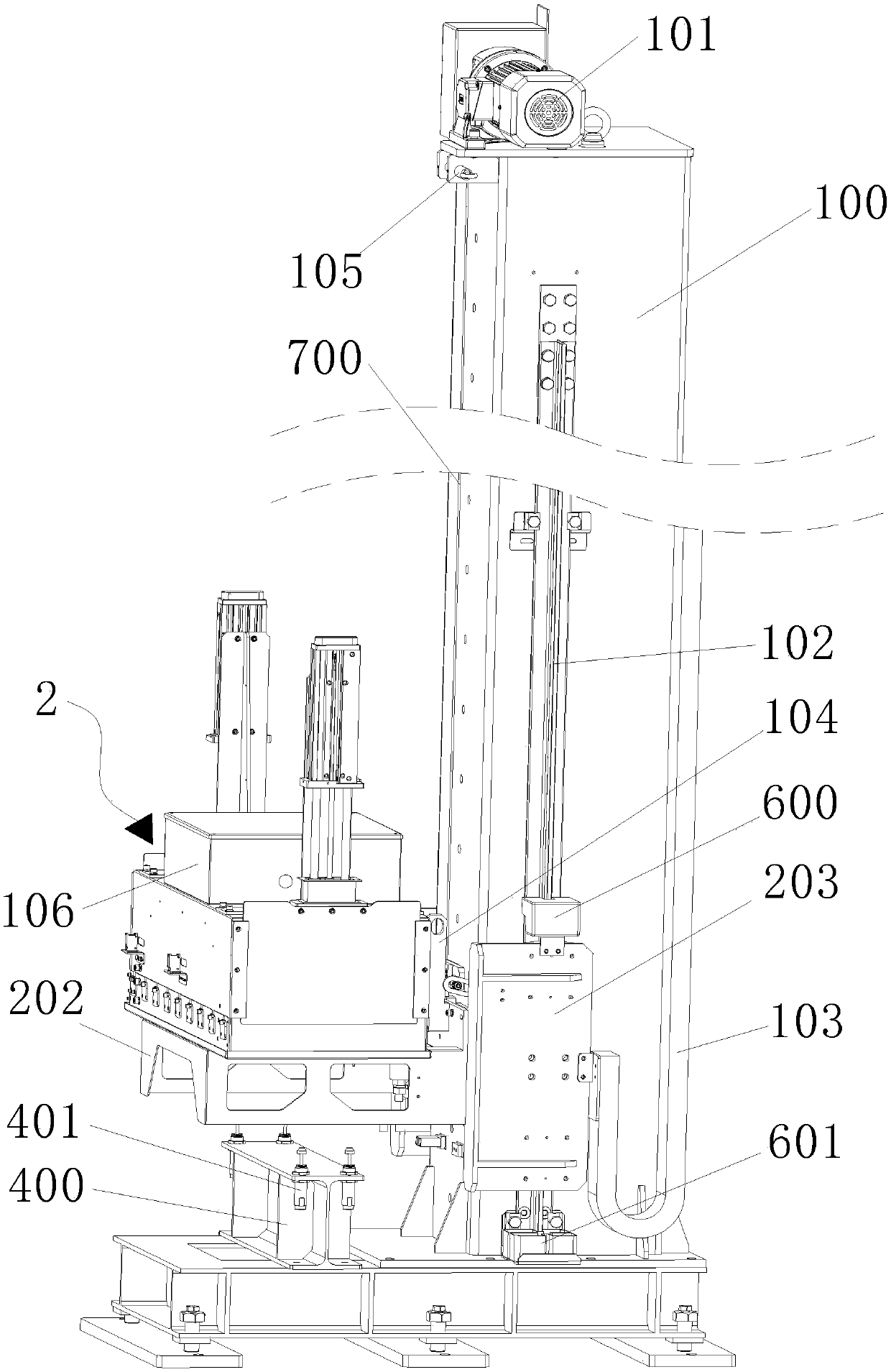

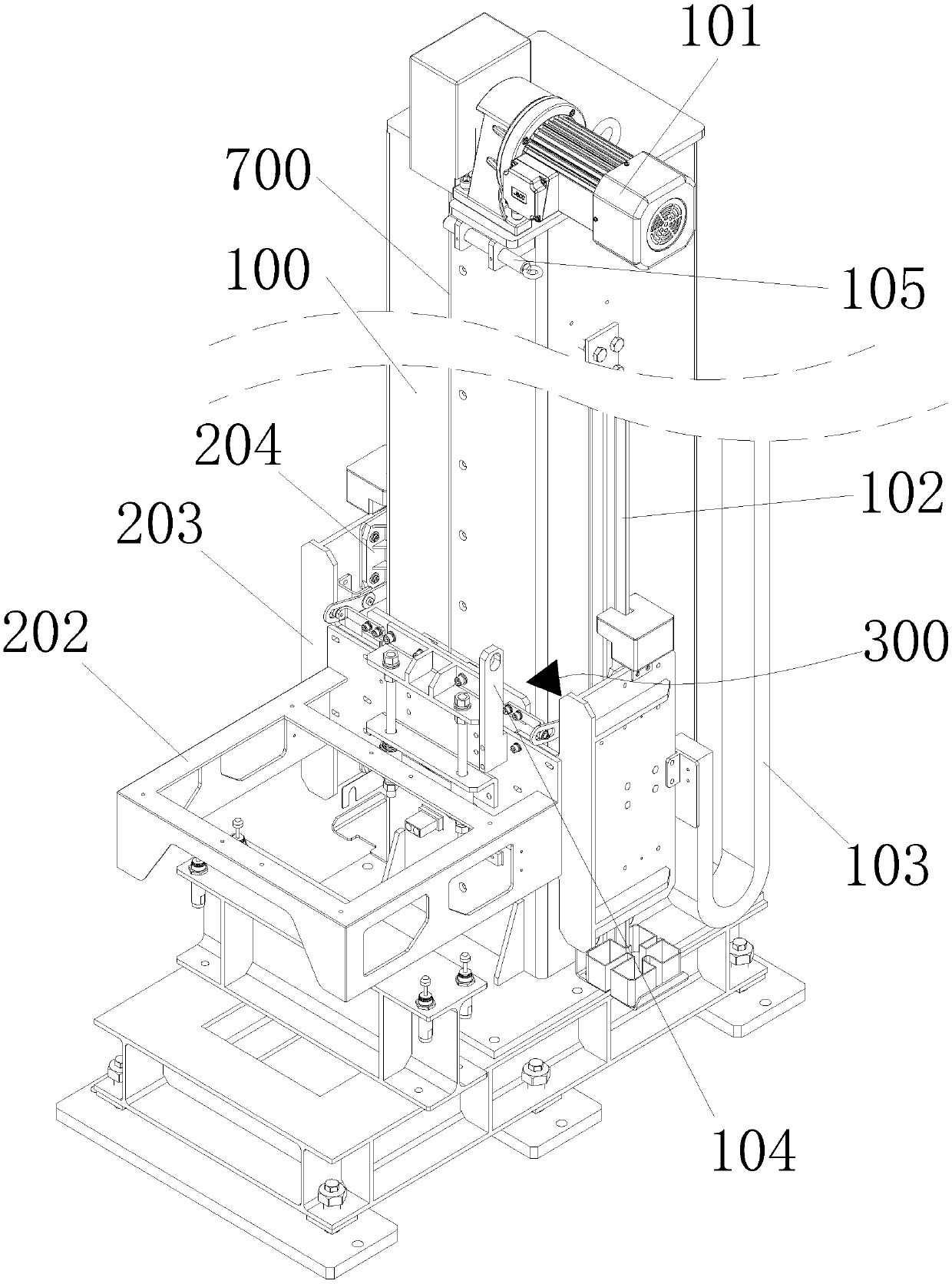

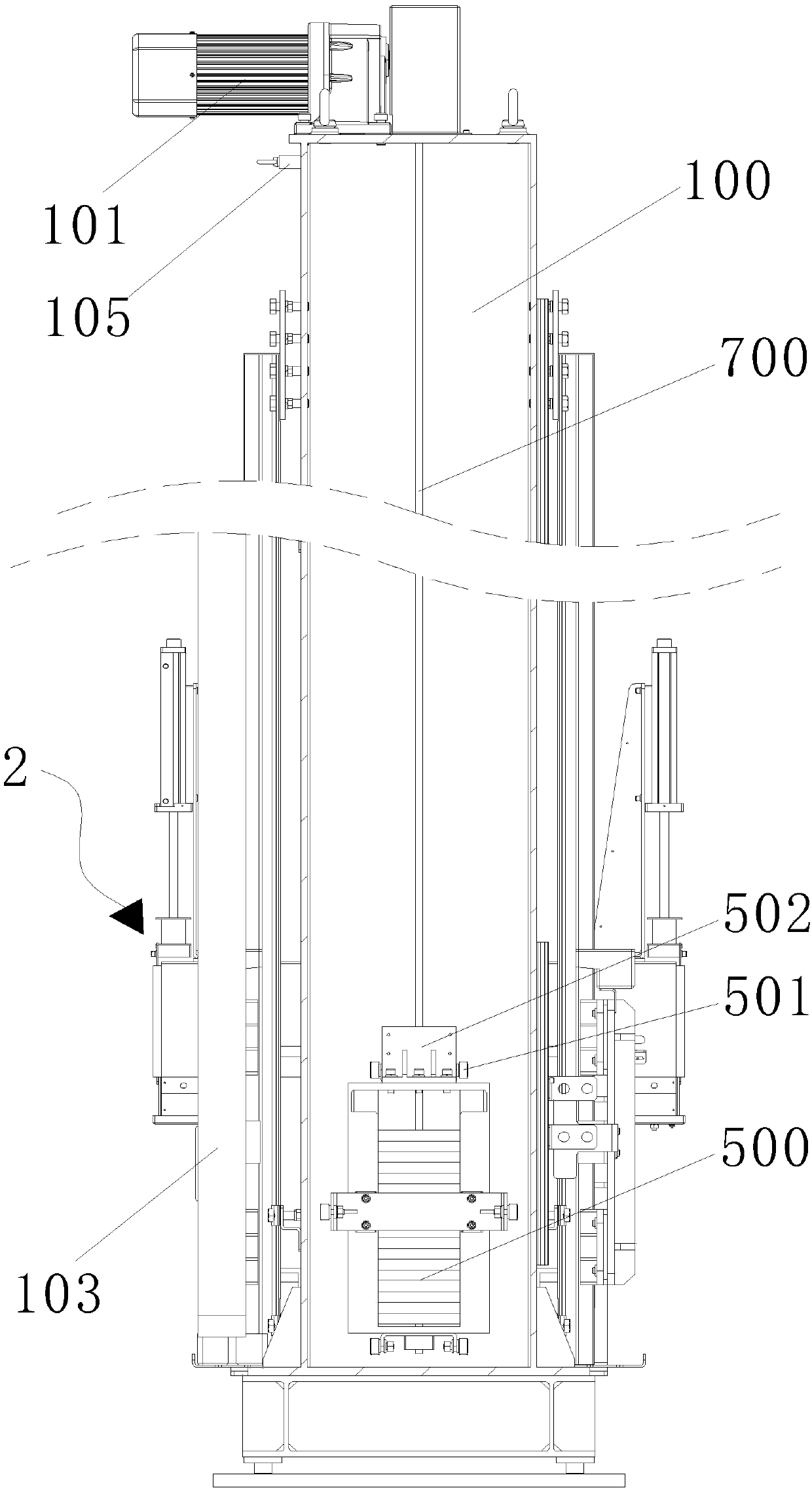

[0033] refer to Figure 1 ~ Figure 3 As shown, the present invention discloses a direction-changing docking dust suppression hoist, which includes a hoisting tower 100 , a hoisting motor 101 , a hoisting platform 202 , a guard plate 203 and a counterweight 500 .

[0034] Two lifting guide rails 102 are symmetrically arranged on both sides of the lifting tower 100 along the vertical direction.

[0035] The upper and lower ends of the guard plate 203 facing the lifting tower 100 are provided with chute 204, and the chute 204 is clamped on the lifting guide rail 102, so that the guard plate 203 is smooth when sliding up and down.

[0036] An oil box 600 is arranged on the upper part of the guard plate 203 , and the oil box 600 is clamped on the lifting guide rail 102 . Lubricating oil is housed in the oil box 600, which provides lubrication for the lifting guide rail 102 during the sliding process. The lower part of the lifting guide rail 102 is provided with an oil collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com