Storage type die head of multi-layer co-extrusion blow molding machine with good using effect

A multi-layer co-extrusion and plastic machine storage technology, which is applied in the field of multi-layer co-extrusion blow molding machine material storage die head, can solve the problems of material clumping, blockage of the discharge port, and material shortage in the storage bin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

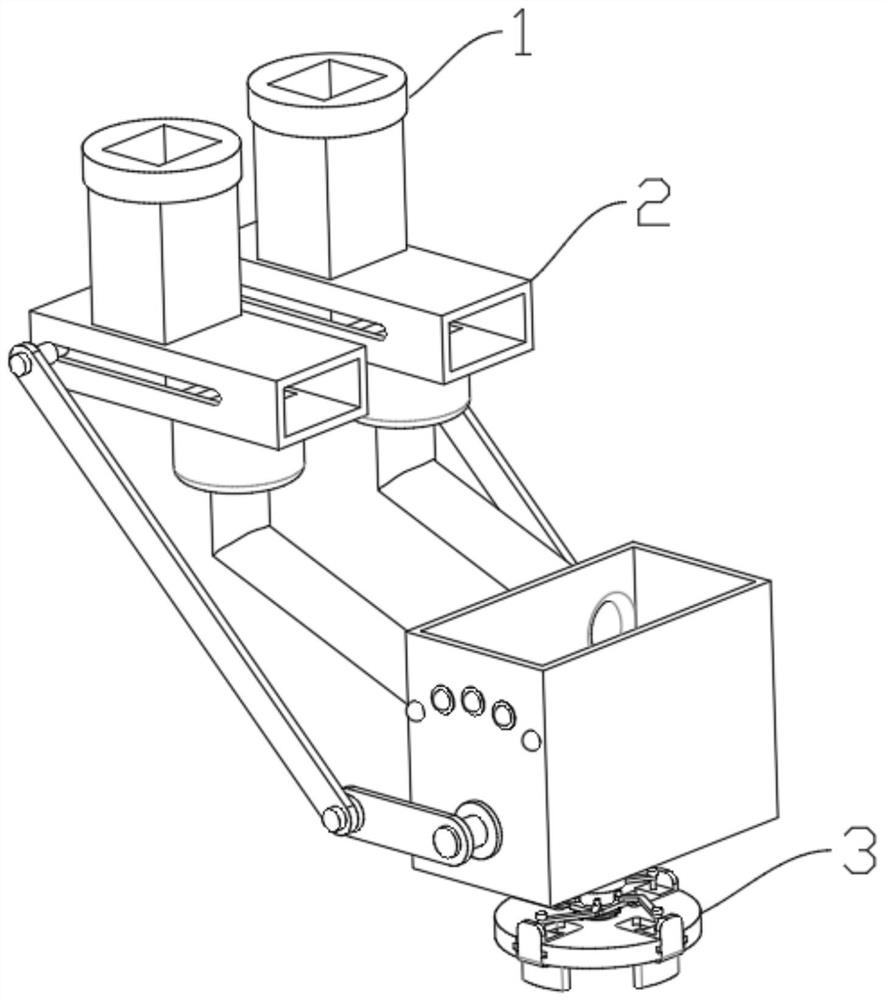

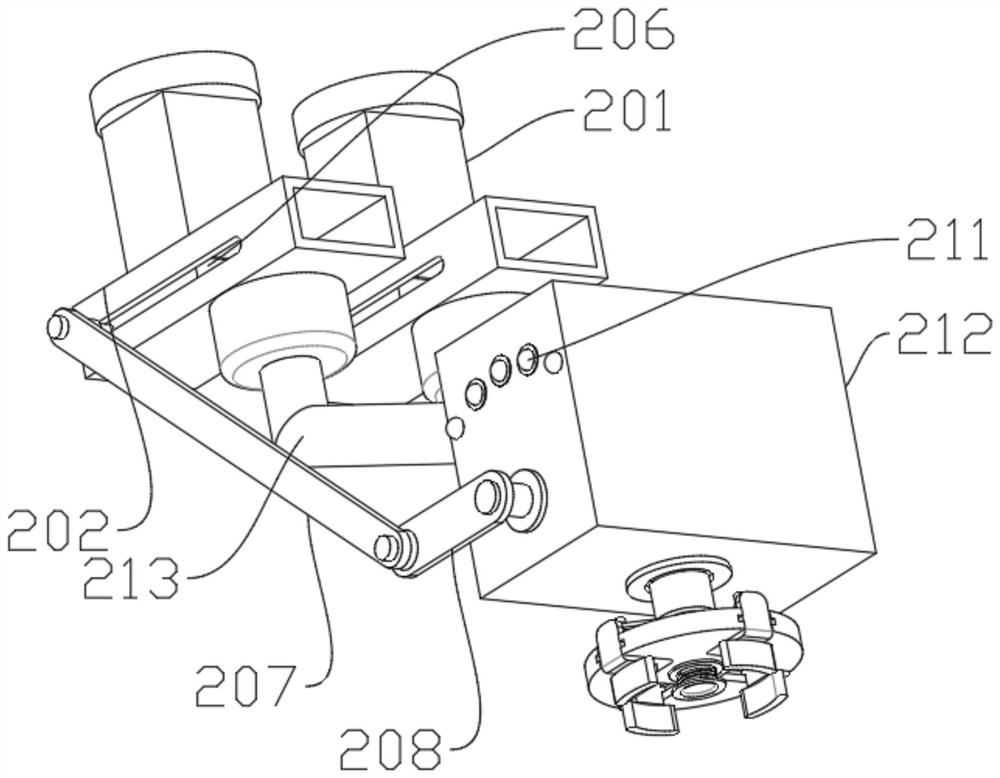

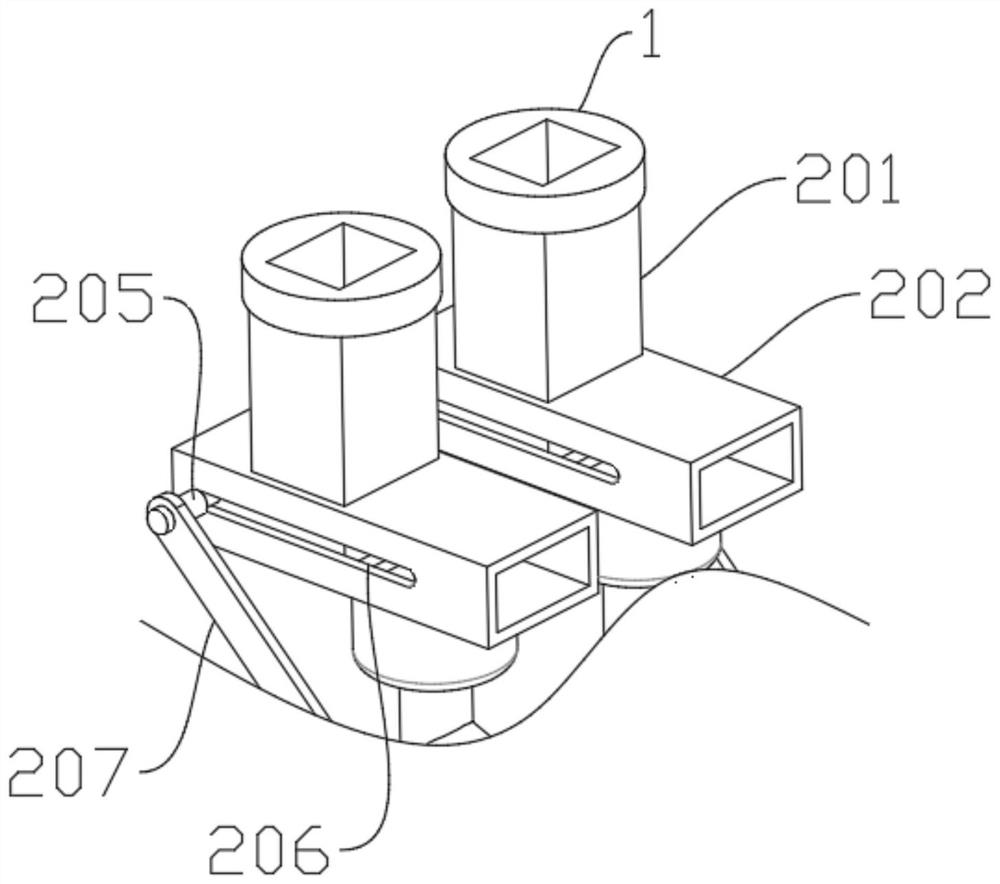

[0032] Please refer to Figure 2 to Figure 6 As shown in the figure, a multi-layer co-extrusion blow molding machine storage-type die head with better use effect includes a twin feeding butt joint 1, and two continuous quantitative feeding and storage mechanisms 2 are arranged at the lower end of the twin feeding butt joint 1. A die head replacement mechanism 3 is arranged below the continuous quantitative feeding and storage mechanism 2. The continuous quantitative feeding and storage mechanism 2 includes a twin stacking square tube 201 and a sliding bin 202. The ends of the twin stacking square tube 201 are fixedly connected with two sliding blocks. In the warehouse 202, both ends of the positioning rod 205 are rotatably connected with a long rod 207, the long rod 207 is rotatably connected with a short rod 208, and the short rod 208 is rotatably connected with a spraying push rod 209, and the spraying push rod 209 is rotatably connected to the stack. Inside the silo 212, th...

Embodiment 2

[0036] Please refer to Figure 7 and Figure 8As shown, the die replacement mechanism 3 includes a hollow cylinder 301, a square plate 302, a curved rod 303, an arc splint 304, and a cross-slotted disc 305. There is a square plate 302, and the square plate 302 is connected with a plurality of bending rods 303 in multi-directional and equidistant rotation. One end of the bending rods 303 is rotatably connected with an arc splint 304. The arc splint 304 is slidably connected to the cross groove plate 305. The outer surface is fixedly connected with an outer thread sleeve 307, the upper end of the outer thread sleeve 307 is threadedly connected with an inner thread sleeve 306, the outer surface of the inner thread sleeve 306 is fixedly connected to the cross groove plate 305, and the outer surface of the hollow cylinder 301 is sleeved with a return spring 308 .

[0037] Working principle: When it is necessary to blow molding different molds, and it is necessary to replace the d...

Embodiment 3

[0039] Please refer to Figure 1 to Figure 8 As shown in the figure, a multi-layer co-extrusion blow molding machine storage-type die head with better use effect includes a twin feeding butt joint 1, and two continuous quantitative feeding and storage mechanisms 2 are arranged at the lower end of the twin feeding butt joint 1. A die head replacement mechanism 3 is arranged below the continuous quantitative feeding and storage mechanism 2. The continuous quantitative feeding and storage mechanism 2 includes a twin stacking square tube 201 and a sliding bin 202. The ends of the twin stacking square tube 201 are fixedly connected with two sliding blocks. In the warehouse 202, both ends of the positioning rod 205 are rotatably connected with a long rod 207, the long rod 207 is rotatably connected with a short rod 208, and the short rod 208 is rotatably connected with a spraying push rod 209, and the spraying push rod 209 is rotatably connected to the stack. Inside the silo 212, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap