Down lamp suitable for different mounting holes

A technology of mounting holes and downlights, which is applied to the parts of lighting devices, lighting devices, lighting auxiliary devices, etc., can solve the problem that the downlight cannot be changed in the installation method, and achieve the effect of convenient installation and selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Attached to the following Figure 1 to Figure 4 This application will be described in further detail.

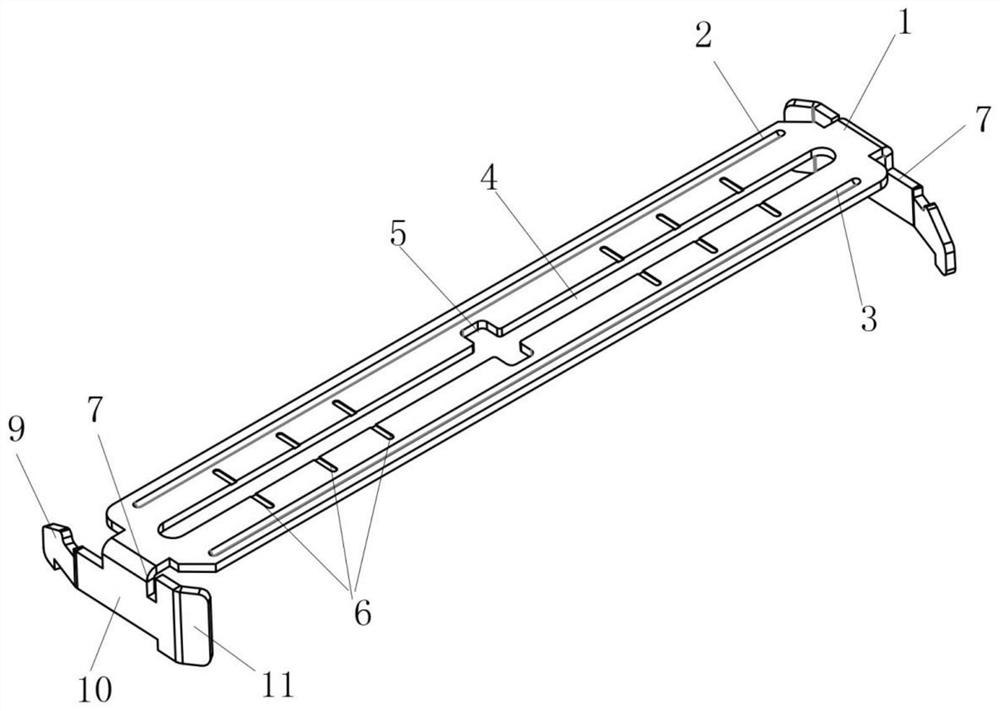

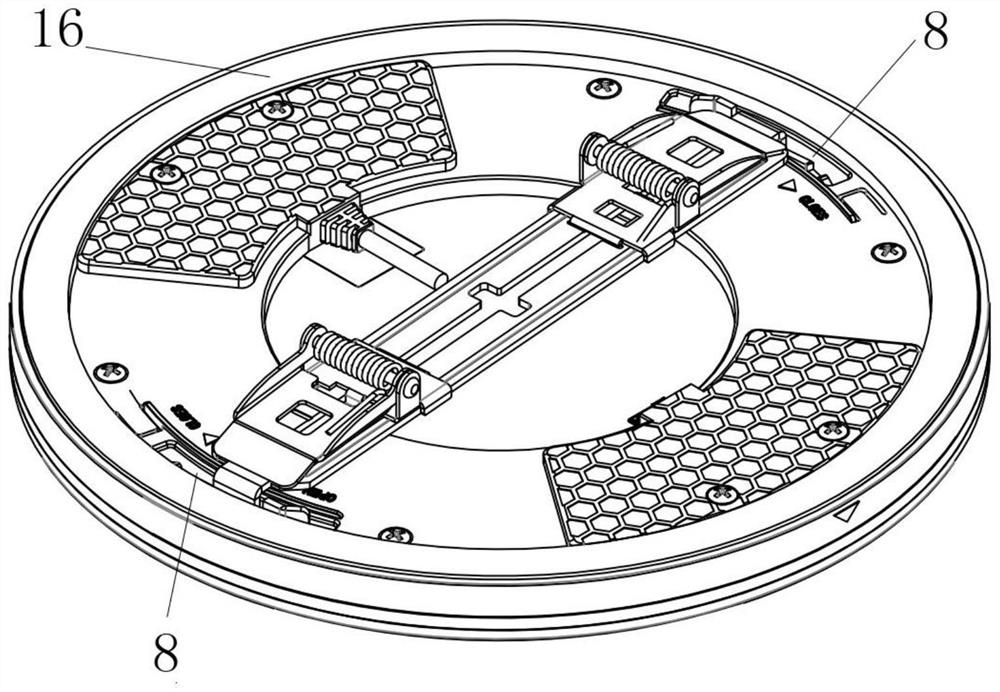

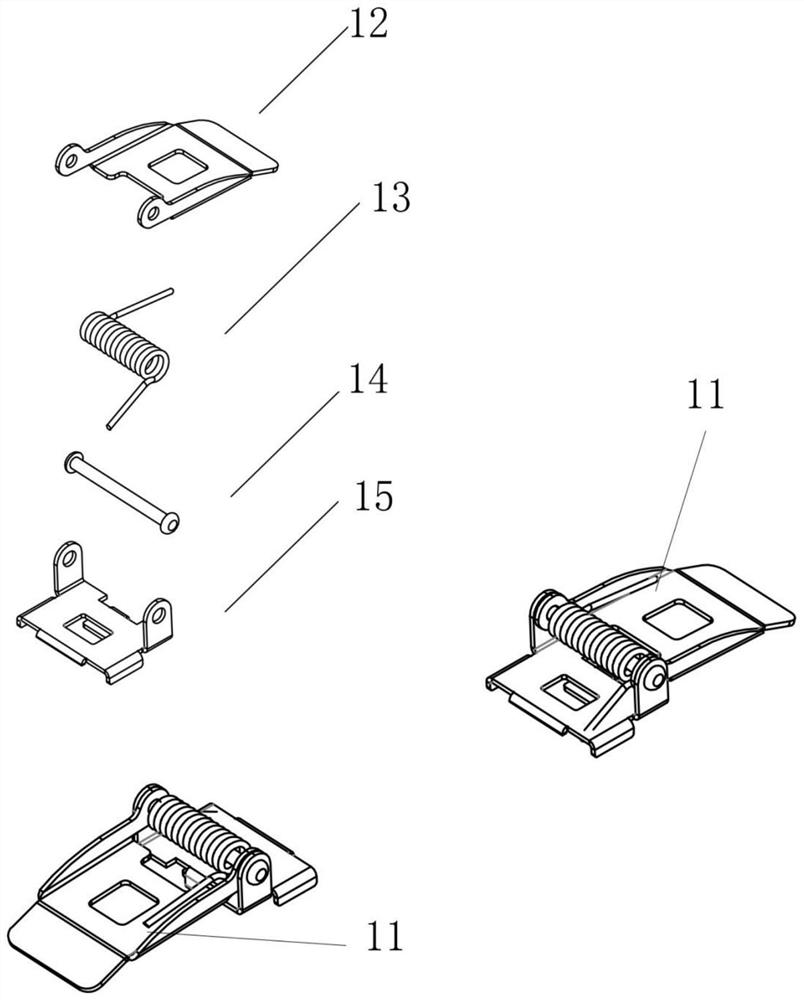

[0018] The embodiment of the present application discloses a downlight that can be adapted to different mounting holes. refer to Figure 1 to Figure 4 , which can be suitable for downlights with different mounting holes, including the main body of the downlight, the rear cover 16 and the mounting bracket 1, the main body of the downlight is fixed on the rear cover 16, and the two sides of the top of the rear cover 16 are provided with The mounting bracket rotation hole 8, the mounting bracket 1 is fixed on the rear cover plate 16 or separated from the rear cover plate 16 through the mounting bracket rotation hole 8, and the installation bracket 1 is buckled with a replaceable installation shrapnel .

[0019] refer to figure 1 , the mounting bracket 1 is in the shape of a long strip, and there are three slots on it. The shrapnel fixing slot 6 is cross-shaped, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com