Automatic wheel rim wiping method and equipment

An automatic wiping and wheel rim technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of low efficiency, large occupied area and high use cost, and achieve fast switching and energy saving. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

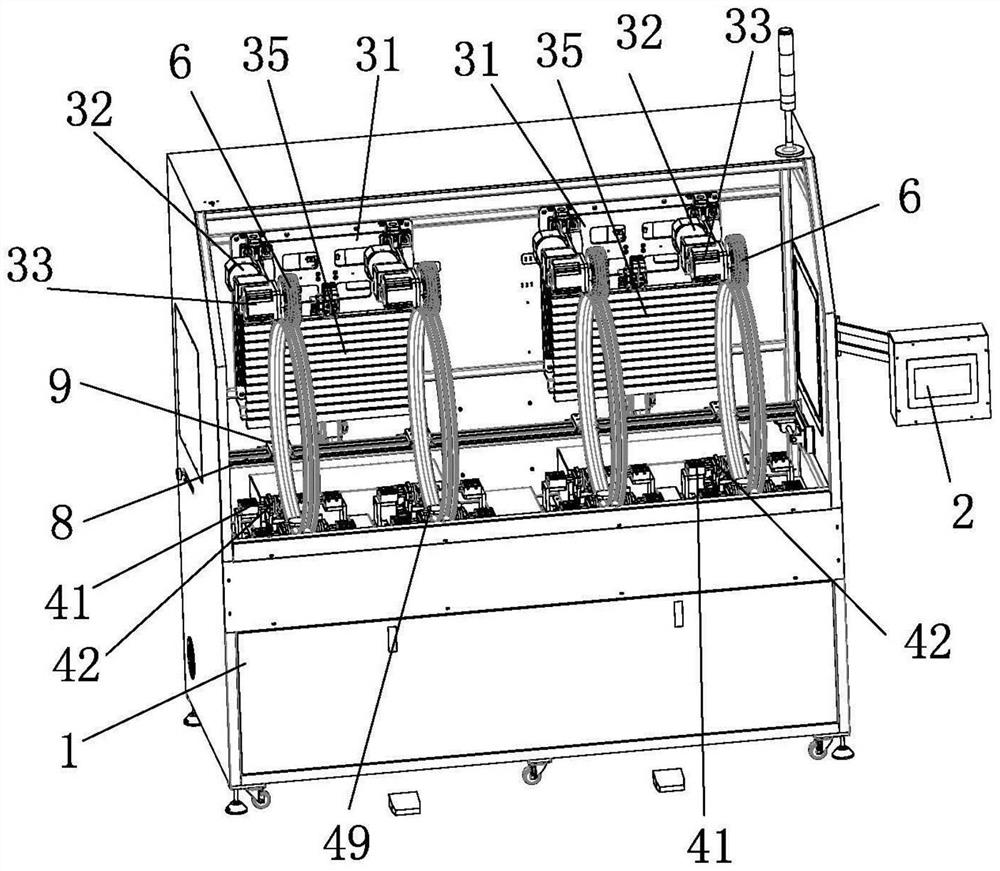

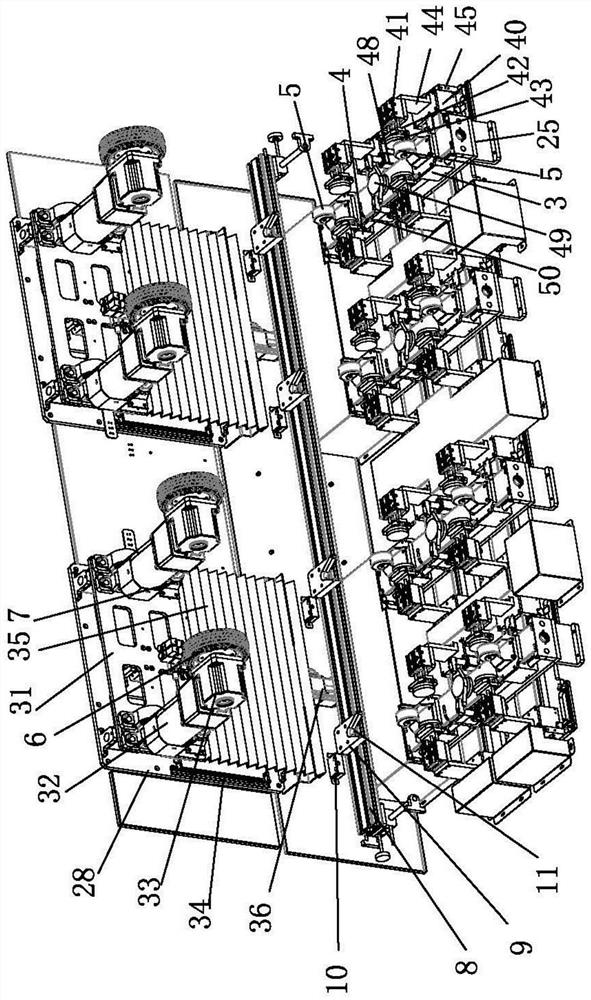

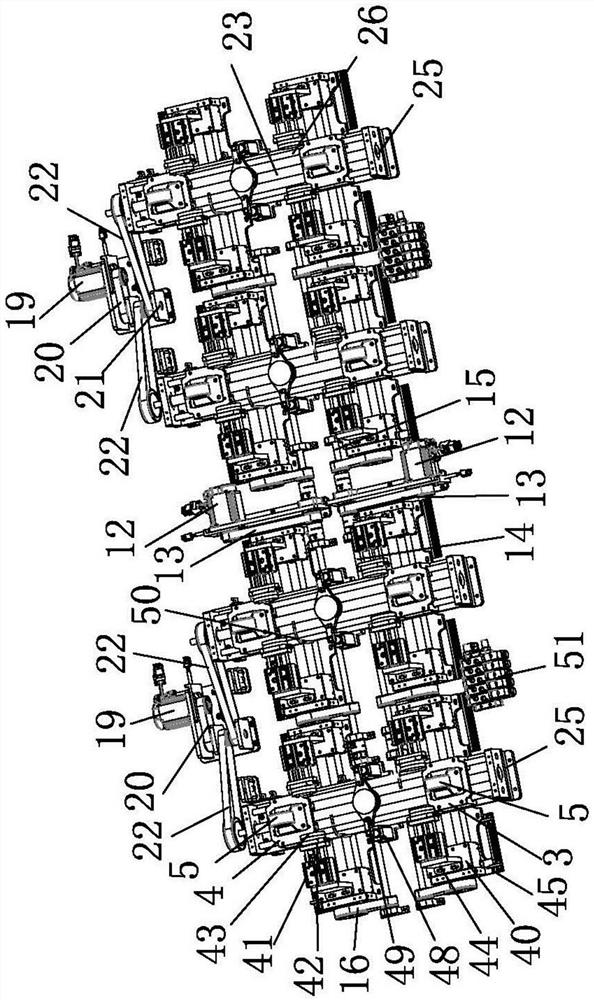

[0056] Example: see Figure 1 to Figure 7 , the present embodiment provides an automatic wiping method for a wheel rim, which comprises the following steps:

[0057] (1) A wiping mechanism is provided, and the wiping mechanism includes an X-axis adjustment device, a Y-axis adjustment device and a Z-axis adjustment device;

[0058] (2) A wheel rim support table is provided on the Y-axis adjusting device. The wheel rim support table includes a front wheel rim support table 3 and a rear wheel rim support table 4. The rim support table plays the role of the Y-axis adjusting device. Move down along the Y-axis, and move in the opposite direction through the front rim support 3 and the rear rim support 4, adjust the distance between the front rim support 3 and the rear rim support 4, so as to adapt to different diameter specifications. For the rim, a rim rotation auxiliary wheel 5 is arranged on the upper end of the rim support table; on both sides of the Y-axis adjusting device, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com