Online coking coal blending regulation and control method

A coal blending and coal blending technology, applied in solid fuel, petroleum industry, fuel, etc., can solve problems such as uneven coking coal blending, achieve the effects of reducing the risk of coal segregation, precise coking coal blending, and avoiding excessive crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

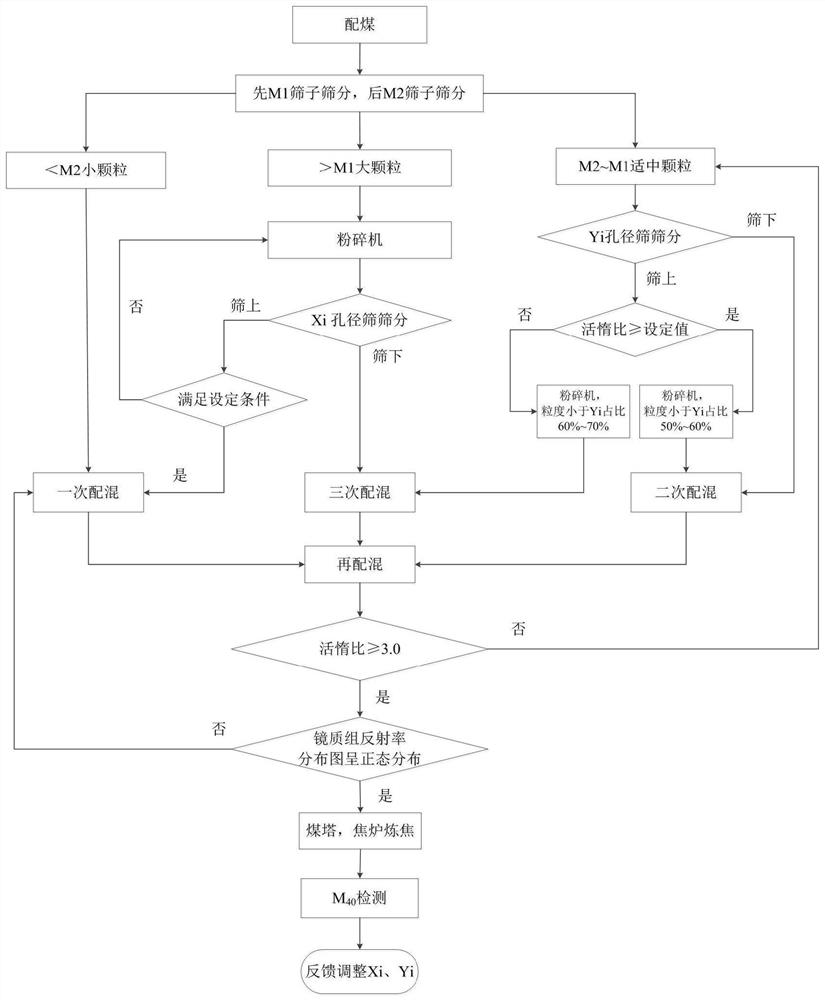

[0026] A method for coking and blending of weakly cohesive coal based on the particle size of coal powder is characterized in that: figure 1 shown.

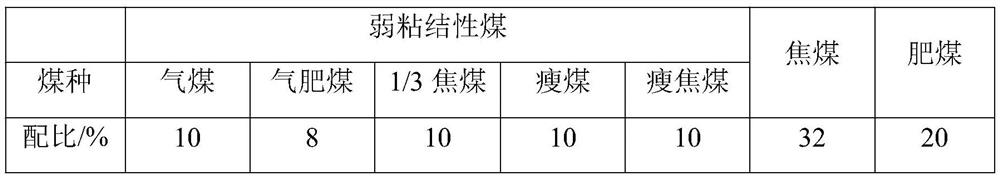

[0027] 1) Coal blending: the weakly caking coal with Rmax 1.6 is lean coal and lean coking coal, 1.2 < Rmax≤1.6 coking coal and 0.9≤Rmax≤1.2 fat coal are blended according to the proportions in Table 1;

[0028] Table 1 Proportion of various coal types

[0029]

[0030] 2) Grain size division: Taking 6mm and 1mm grain size as the screening limit, the blended coal is divided into 3 grain size ranges after continuous screening: ①>6mm large particles, accounting for 38%; ②1-6mm moderate particles, accounting for 18% ; ③ Small particles less than 1mm account for 44%;

[0031] 3) Treatment of large particle coal powder: the large particles > 6 mm in step 2) are pulverized with coal, and after pulverization, sieve with a sieve with an aperture of Xi = 3 mm to obtain the under-sieve and over-sieve respectively; the bond index of ...

Embodiment 2

[0038] A method for coking and blending of weakly cohesive coal based on the particle size of coal powder is characterized in that: figure 1 shown.

[0039] 1) Coal blending: the weakly caking coal with Rmax 1.6 is lean coal and lean coking coal, 1.2 < Rmax≤1.6 coking coal and 0.9≤Rmax≤1.2 fat coal are blended according to the proportions in Table 2;

[0040] Table 2 Proportion of various coal types

[0041]

[0042] 2) Grain size division: Taking 6mm and 1mm grain size as the screening limit, the blended coal is divided into 3 grain size ranges after continuous screening: ①>6mm large particles, accounting for 27%; ②1-6mm moderate particles, accounting for 55% ;③<1mm small particles, accounting for 18%;

[0043] 3) Treatment of large-particle pulverized coal: pulverize the large particles > 6 mm in step 2 with coal, and sieve with a sieve with an aperture of Xi = 3 mm after pulverization to obtain the under-sieve and over-sieve material respectively; The setting condit...

Embodiment 3

[0050] A method for coking and blending of weakly cohesive coal based on the particle size of coal powder is characterized in that: figure 1 shown.

[0051] 1) Coal blending: the weakly caking coal with Rmax 1.6 is lean coal and lean coking coal, 1.2 < Rmax≤1.6 coking coal and 0.9≤Rmax≤1.2 fat coal are blended according to the proportions in Table 3;

[0052] Table 3 Proportions of various coal types

[0053]

[0054] 2) Grain size division: With 10mm and 0.5mm grain size as the screening limit, the blended coal is divided into 3 grain size ranges after continuous screening: ①>10mm large particles, accounting for 17%; ②0.5-10mm moderate particles, accounting for than 53%; ③<0.5mm small particles account for 30%;

[0055] 3) Large particle coal powder treatment: pulverize the mixed coal with medium and large particles > 10 mm in step 2), sieve with a sieve with an aperture of Xi=5 mm after pulverization, and obtain the under-sieve and over-sieve material respectively; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com