Liquid storage box, putting device and clothes processing equipment

A technology of feeding device and liquid storage box, which is applied to washing devices, other washing machines, textiles and paper making, etc. It can solve the problems of additive leakage, washing additive container can not be used continuously, poor sealing, etc., and achieves the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

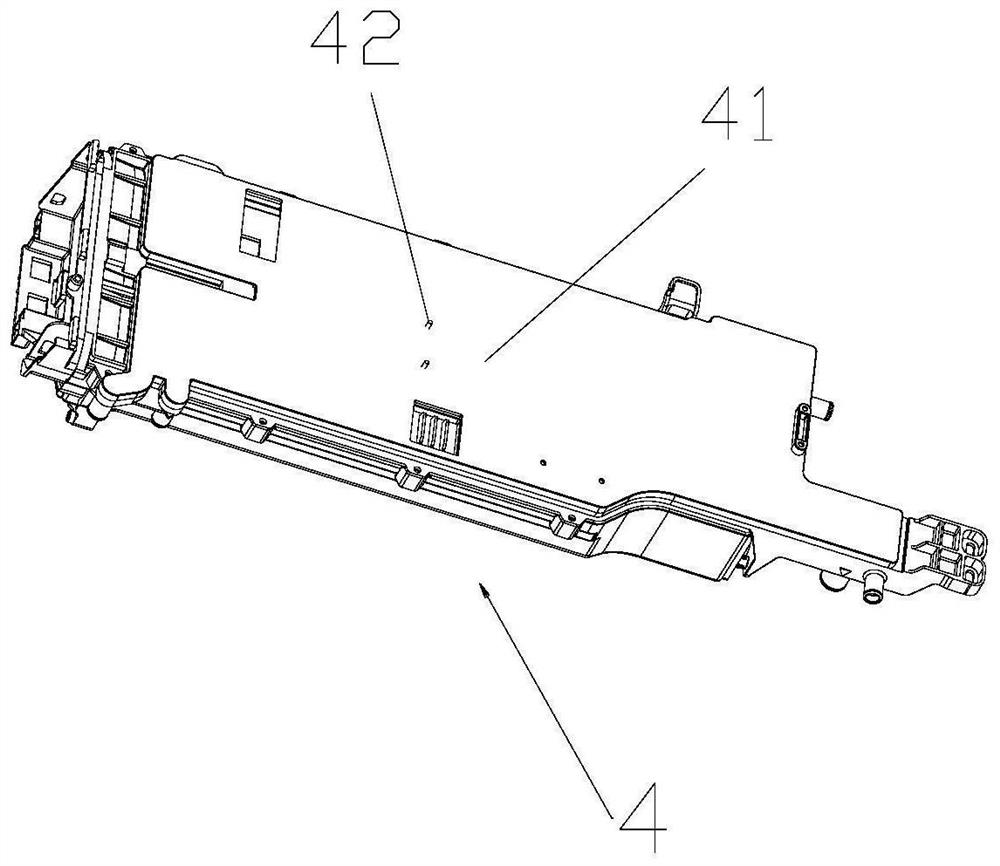

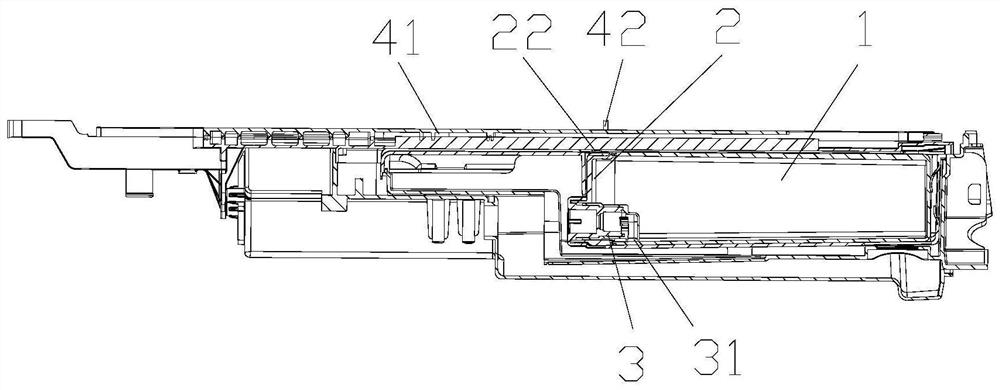

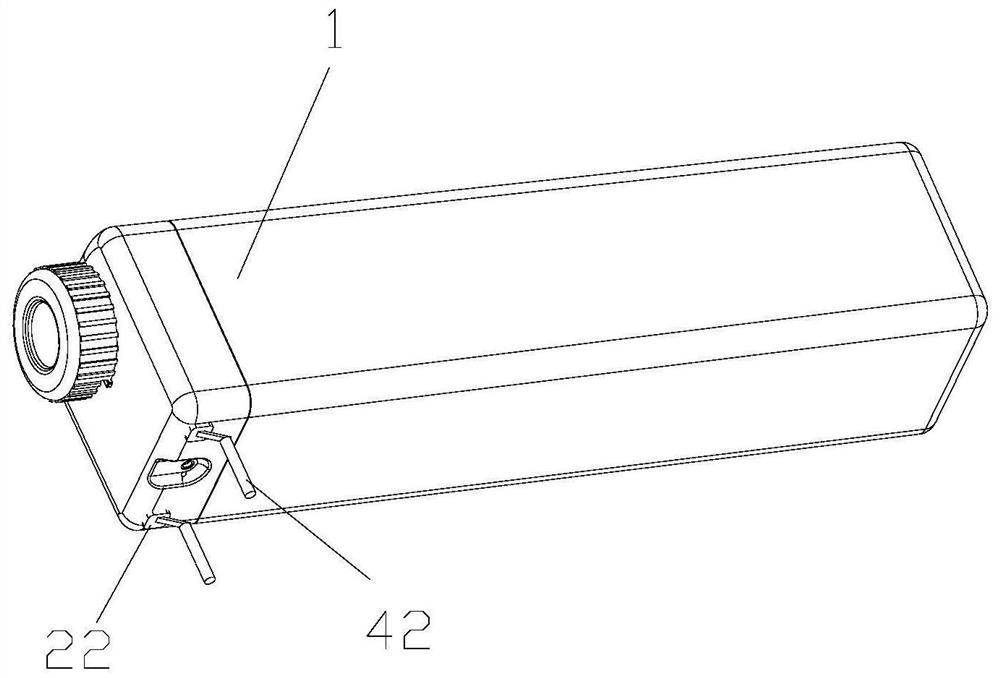

[0051] like Figure 1 to Figure 5As shown, this embodiment provides a liquid storage box 1, and the liquid storage box 1 has a sealed chamber for storing additives. In this embodiment, the chamber inside the liquid storage box 1 is an independently sealed liquid storage chamber , the liquid storage box 1 also has a conductive detection part that can detect the liquid level information of the internal additive. The conductive detection part is formed as a part of the liquid storage box 1. Compared with the existing liquid storage box 1 provided in this embodiment, the liquid storage box 1 The integrity, independent use and reliability of the liquid storage box in the technology are higher.

[0052] The liquid storage box 1 provided in this embodiment has a conductive detection part that can detect the liquid level information of the internal additive, which solves the problem of complicated assembly between the existing liquid storage box 1 and the conductive probe 2, poor seal...

Embodiment 2

[0092] like Figure 6 to Figure 13 As shown, this embodiment introduces a liquid storage box on the basis of the first embodiment, the liquid storage box 1 has a sealed chamber for storing additives, and the outer wall of the liquid storage box 1 is provided with at least two The conductive contact pieces 22 in the chamber that are in contact with the additive, and the combination of the number and position of the conductive contact pieces 22 provided on the liquid storage box correspond to the types of additives stored in the liquid storage box 1 .

[0093] In this application, by arranging a plurality of conductive contact pieces 22 exposed on the outer wall on the liquid storage box 1, any one of the information such as the number, relative position, and setting position on the liquid storage box 1 of the conductive contact pieces 22 or the like is used. In combination, the types of additives contained in the liquid storage box 1 can be accurately identified, thereby achiev...

Embodiment 3

[0106] This embodiment also has the following technical features based on the above-mentioned first embodiment and second embodiment:

[0107] like Figure 5 to Figure 9 , Figure 12 , Figure 13 As shown, this embodiment introduces a liquid storage box, the liquid storage box 1 has a sealed chamber for storing additives, and the outer surface of the liquid storage box 1 is provided with more than two conductive contacts 22 , the two conductive contacts 22 are separated by a distance, so that the conductive contacts 22 are distributed in different positions of the liquid storage box 1 in a changeable position. The number of conductive contacts 22 provided on the liquid storage box 1 The combination of , position corresponds to the type of additives stored in the liquid storage box.

[0108] In this embodiment, the quantity information of the conductive contacts 22 is the number of the conductive contacts 22 provided on the outer surface of the liquid storage box 1; for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com