Quick pressing equipment and pressing method for water baked buns

A water-baked steamed bun, fast technology, applied in dough forming machinery or equipment, baking, food science, etc., can solve the problems of low pressing efficiency, stagnation of feeding mechanism, etc., and achieve the effect of improving pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

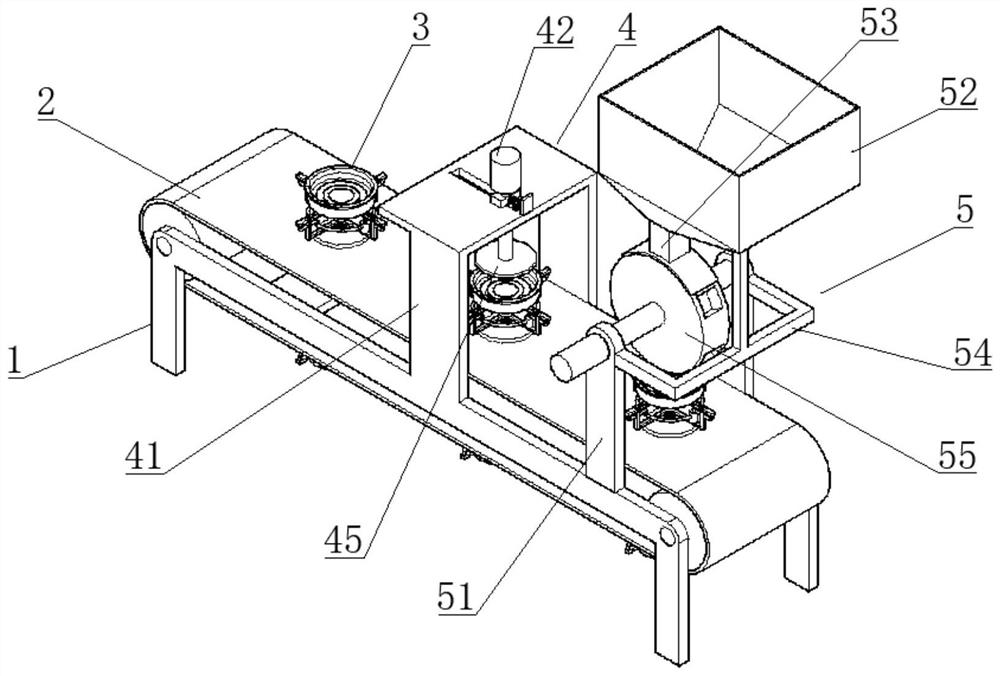

[0035] like Figure 1-5As shown in the figure, a rapid pressing device for water-roasted buns includes a pressing table 1, on which a pressing belt 2 is driven to rotate by a conveying wheel, and a pressing lower die 3 in a linear array along the length direction of the pressing belt 2 is fixedly connected to the pressing belt 2. , the pressing table 1 is fixedly connected to the pressing upper die 4, the pressing lower die 3 includes a lower pressing plate 33, the pressing upper die 4 includes a pressing frame 41, the pressing frame 41 is slidably connected to the sliding block, the pressing cylinder 42 is fixed on the sliding block, and the pressing The piston rod of the cylinder 42 penetrates the slider and is slidably connected to the slider, the bottom end of the piston rod of the pressing cylinder 42 is fixedly connected to the upper pressure plate, and the feeding mechanism 5 is connected to the pressing table 1 .

[0036] The feeding mechanism 5 places the agent on the...

Embodiment 2

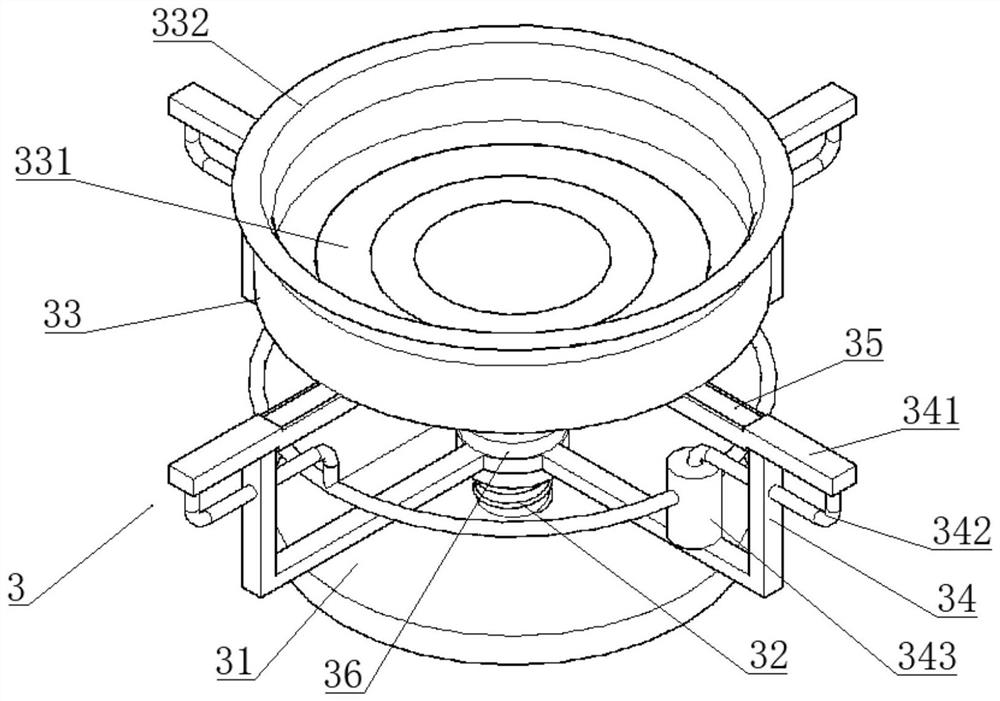

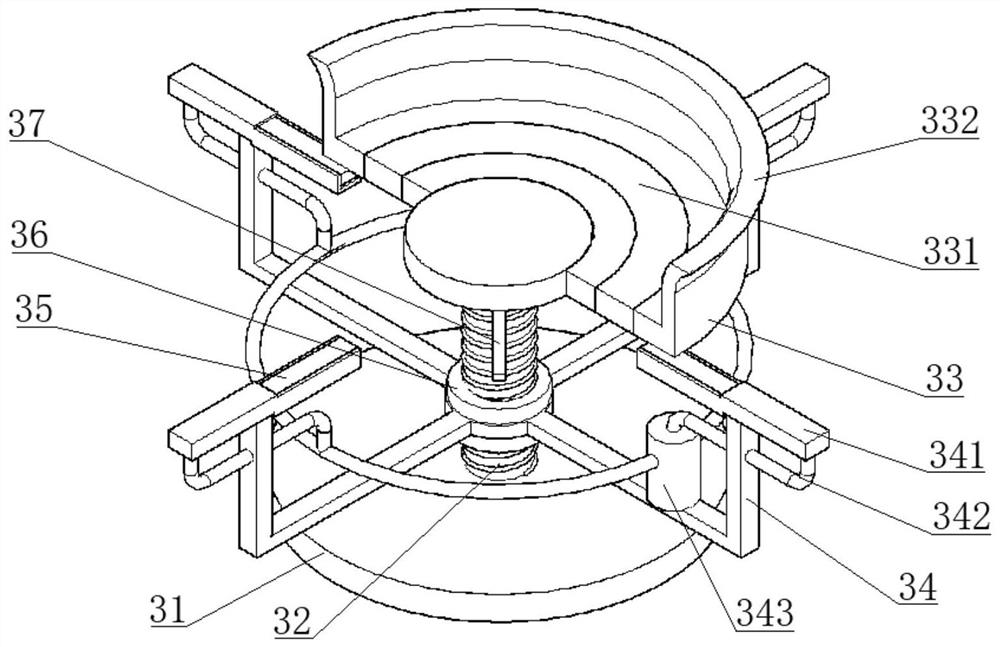

[0038] like Figure 1-5 As shown in the figure, a rapid pressing device for water-roasted buns includes a pressing table 1, on which a pressing belt 2 is driven to rotate by a conveying wheel, and a pressing lower die 3 in a linear array along the length direction of the pressing belt 2 is fixedly connected to the pressing belt 2. , the pressing table 1 is fixedly connected to the pressing upper die 4, the pressing lower die 3 includes a lower pressing plate 33, the pressing upper die 4 includes a pressing frame 41, the pressing frame 41 is slidably connected to the sliding block, the pressing cylinder 42 is fixed on the sliding block, and the pressing The piston rod of the cylinder 42 penetrates the slider and is slidably connected to the slider, the bottom end of the piston rod of the pressing cylinder 42 is fixedly connected to the upper pressure plate, the feeding mechanism 5 is connected to the pressing table 1, and the lower pressure plate 33 includes a fixed plate 31. T...

Embodiment 3

[0041] like Figure 1-6 As shown in the figure, a rapid pressing device for water-roasted buns includes a pressing table 1, on which a pressing belt 2 is driven to rotate by a conveying wheel, and a pressing lower die 3 in a linear array along the length direction of the pressing belt 2 is fixedly connected to the pressing belt 2. , the pressing table 1 is fixedly connected to the pressing upper die 4, the pressing lower die 3 includes a lower pressing plate 33, the pressing upper die 4 includes a pressing frame 41, the pressing frame 41 is slidably connected to the sliding block, the pressing cylinder 42 is fixed on the sliding block, and the pressing The piston rod of the air cylinder 42 penetrates the slider and is slidably connected to the slider, the bottom end of the piston rod of the pressing cylinder 42 is fixedly connected to the upper pressure plate, and a feeding mechanism 5 is connected to the pressing table 1 , and the feeding mechanism 5 is fixed on the pressing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com