Spraying arm for cleaning machine

A spray arm and washing machine technology, applied in the field of spray arms, can solve the problems that the spray head of the spray arm is difficult to meet the cleaning needs, affect the head of the spray water column, and the loss of the capacity of the spray arm, so as to increase the water pressure, improve the Head, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

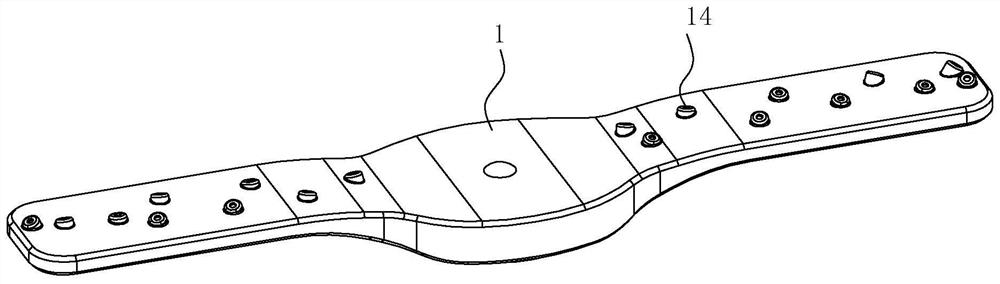

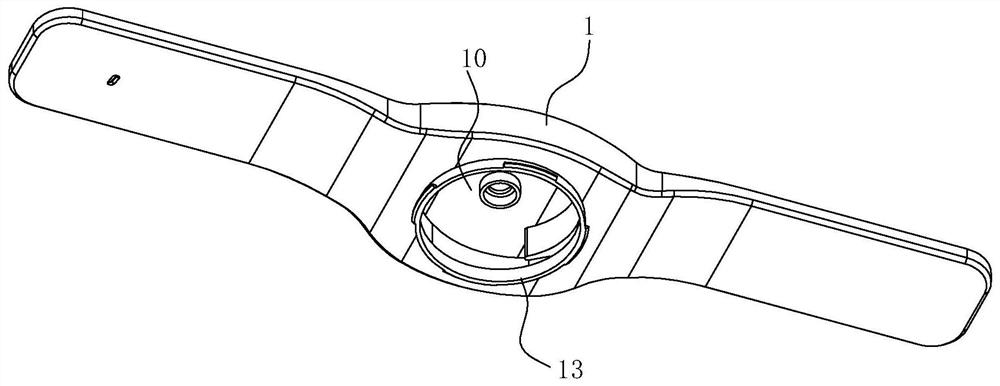

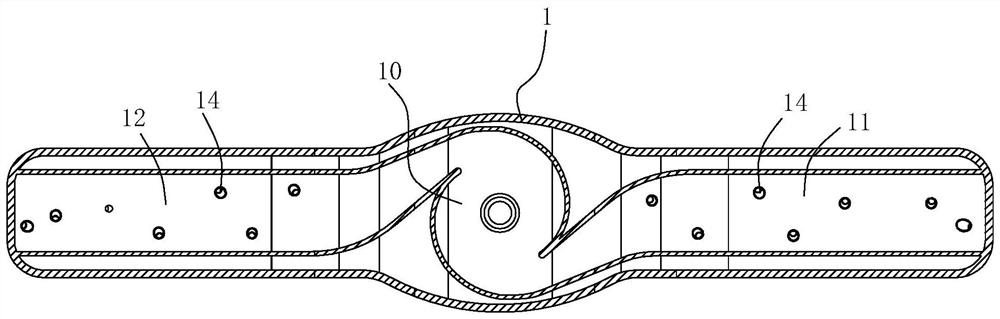

[0039] like Figures 1 to 3 As shown, the spray arm used for the washing machine in this embodiment includes a main body 1 extending along the length direction, a water collecting cavity 10 in the middle of the main body 1, and a first flow connecting with the water collecting cavity 10 on one side of the main body 1 Channel 11, the other side of the main body 1 has a second flow channel 12 that communicates with the water collection cavity 10, the bottom wall of the main body 1 is provided with a water inlet 13 that communicates with the water collection cavity 10, and the top wall of the main body 1 is opened There are water spray holes 14 communicating with the first flow channel 11 and the second flow channel 12 .

[0040] In this embodiment, as Figure 4 As shown, the profile line corresponding to the water collecting cavity 10 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com