Treatment liquid composition for inkjet printing, ink set, and recording method

A technology of inkjet printing and dyeing and recording methods, which is applied in the direction of ink, dyeing method, application, etc., and can solve the problems of color difference bands and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

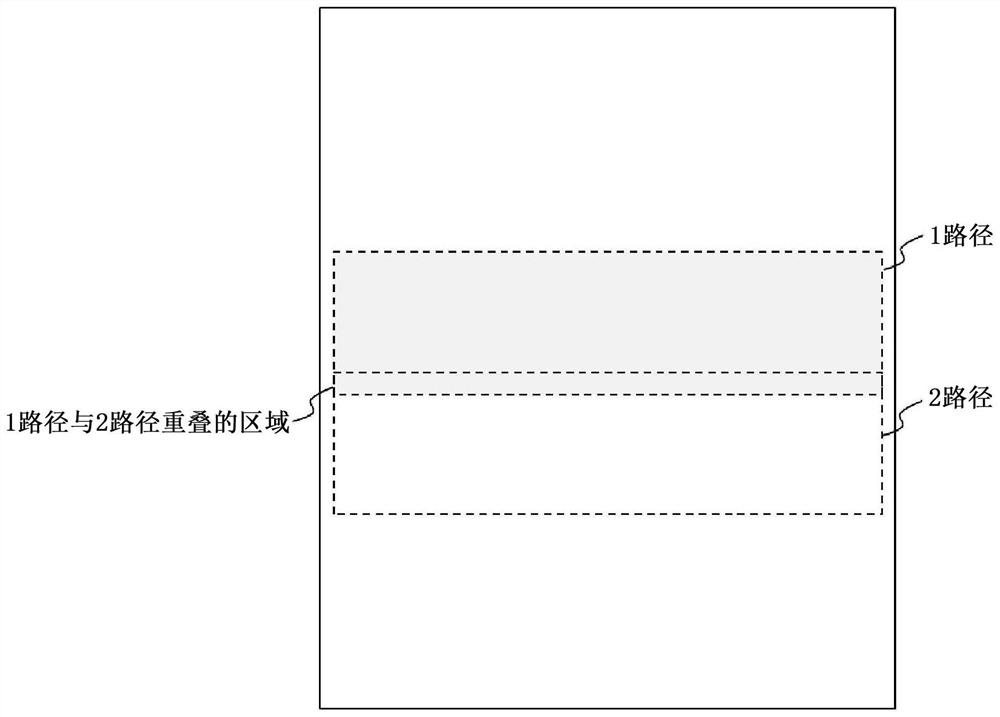

Image

Examples

Embodiment

[0090]Hereinafter, the present invention will be described in more detail using Examples and Comparative Examples. The present invention is not limited at all by the following examples.

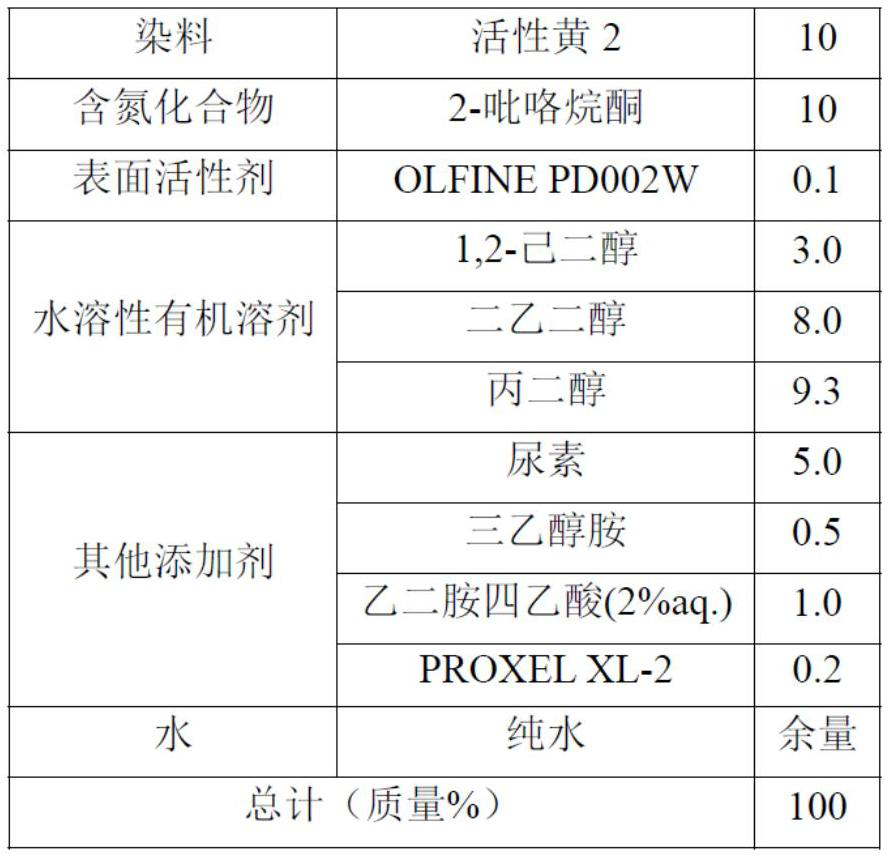

[0091] 1. Preparation example of ink composition

[0092] Each material was mixed according to the composition shown in the following Table 1, and was stirred sufficiently to obtain an ink composition. Specifically, the ink is prepared by uniformly mixing each material and removing insoluble matter with a filter. In addition, in the following Table 1, the unit of a numerical value is mass %, and it is 100.0 mass % in total.

[0093] 【Table 1】

[0094]

[0095] OLFINE PD002W (Acetylene glycol-based surfactant, Nissin Chemical Industry Co., Ltd.)

[0096] PROXEL XL-2 (benzothiazolin-3-one, manufactured by LONZA Japan)

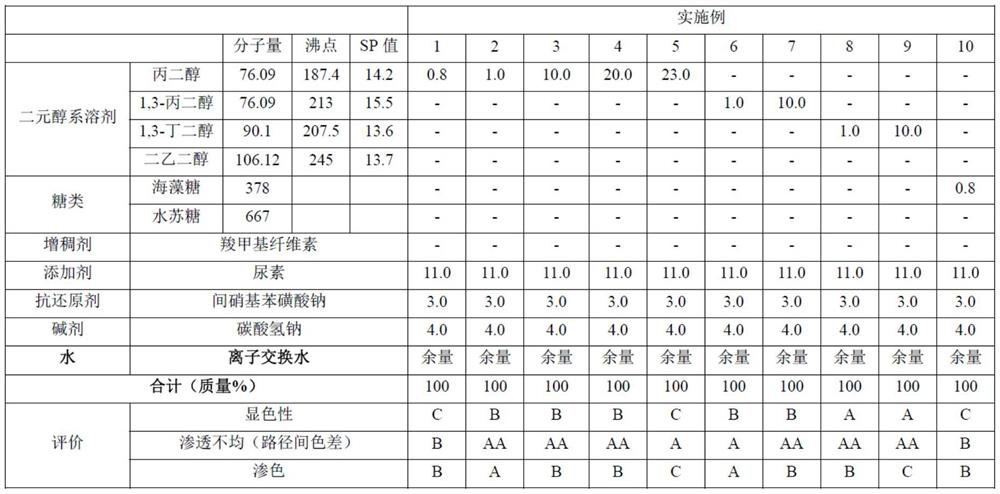

[0097] 2. Preparation example of treatment liquid composition

[0098] The respective materials were mixed according to the compositions shown in the following Tables 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap