Substrate bonding apparatus and substrate bonding method

A bonding device and bonding method technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of reducing the efficiency of bonding devices, vertical alignment deviation, alignment misalignment or distortion, etc., and achieve the effect of reducing coordinate errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the structure of the substrate bonding apparatus and the substrate bonding method according to the embodiment of the present invention will be specifically described with reference to the accompanying drawings.

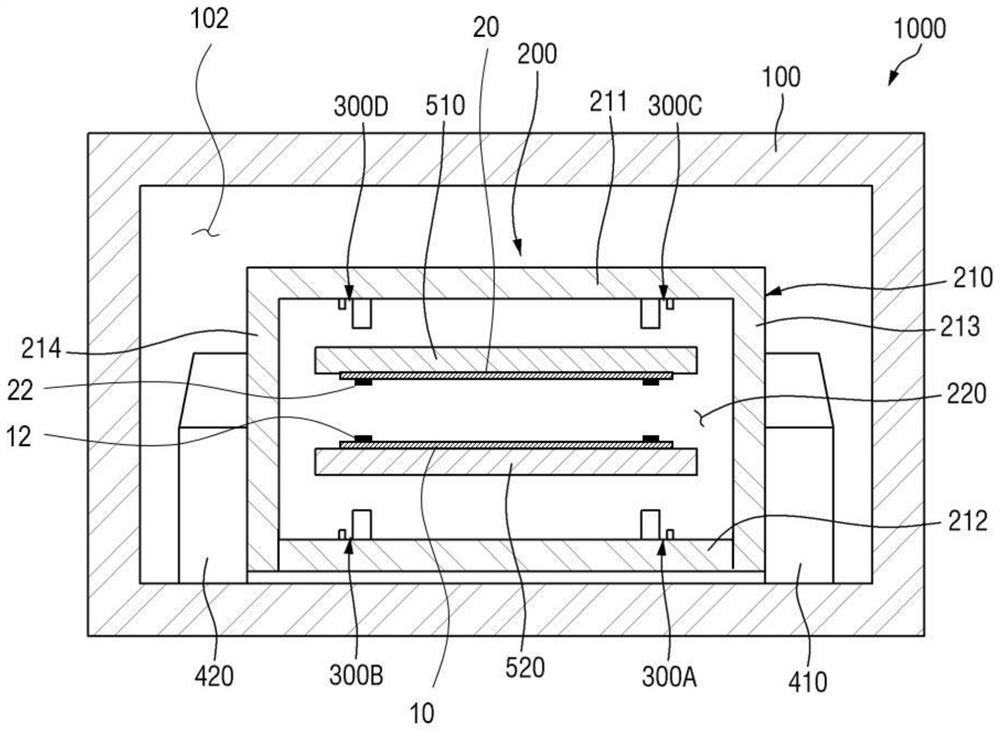

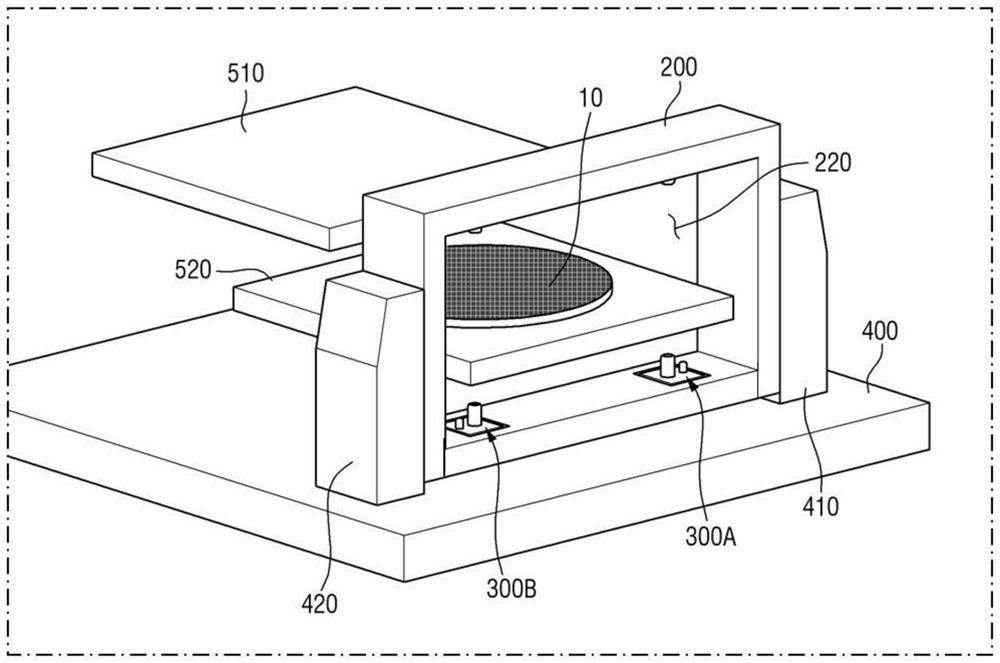

[0048] figure 1 It is a side view of a substrate bonding apparatus 1000 according to an embodiment of the present invention, figure 2 for display figure 1 A perspective view of the internal structure of the substrate bonding apparatus 1000 shown.

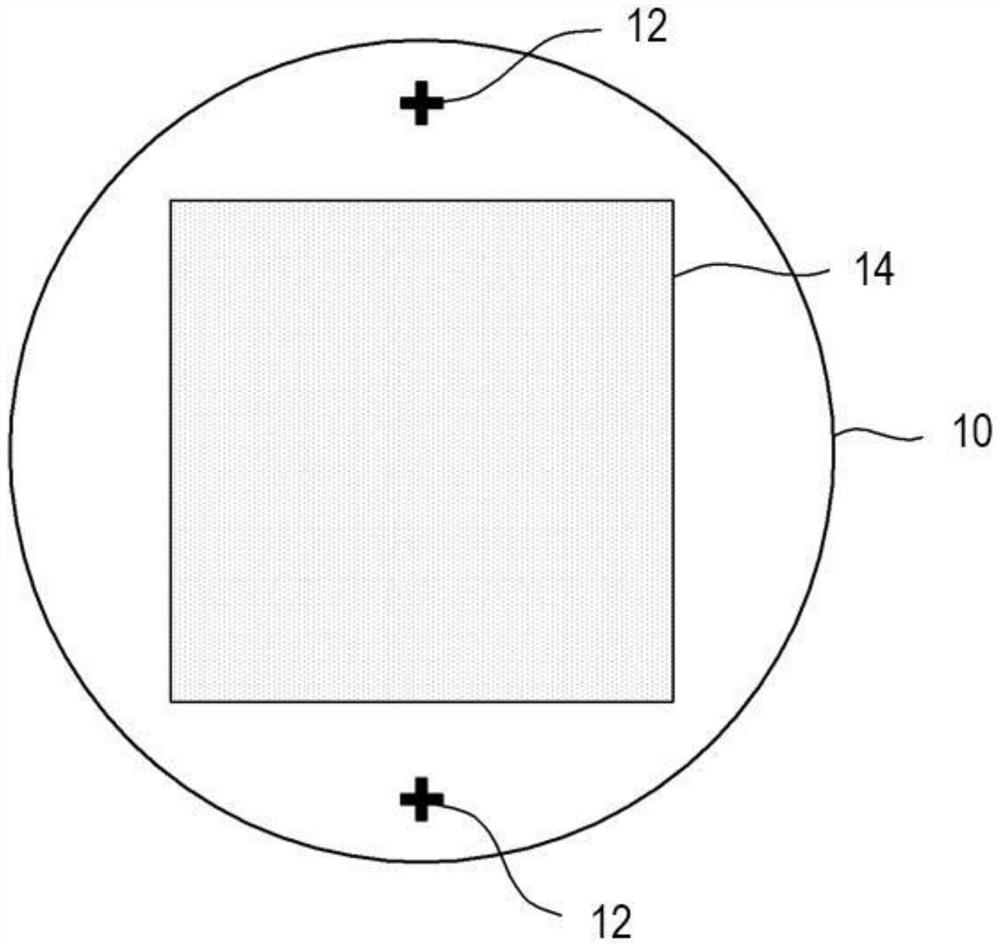

[0049] refer to figure 1 and figure 2 , the substrate bonding apparatus 1000 includes: a cavity 100 ; a first chuck 520 , which is arranged inside the cavity 100 to adsorb the first substrate 10 ; a second chuck 510 to face the first chuck 520 is arranged inside the cavity 100 in a manner of moving vertically and horizontally relative to the first chuck 520 to adsorb the second substrate 20; and the arrangement module 200 has the function of identifying the first chuck 520. The first sorting key 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com