Machine gun frame for combat helicopter

A technology for helicopters and machine guns, applied in aircraft parts, military equipment configuration, transportation and packaging, etc., can solve problems such as the failure of the machine gun frame lifting adjustment mechanism to work normally and the lack of shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

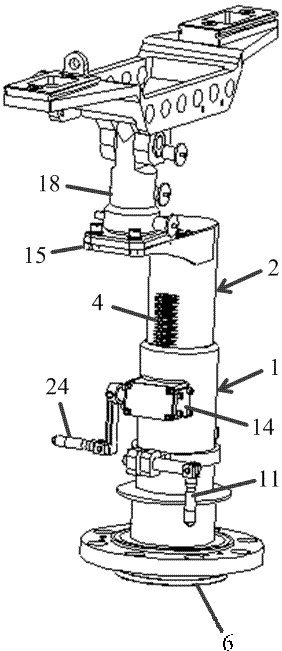

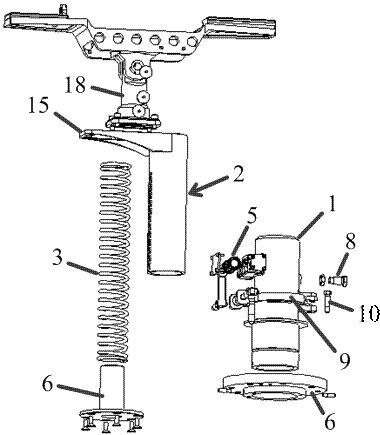

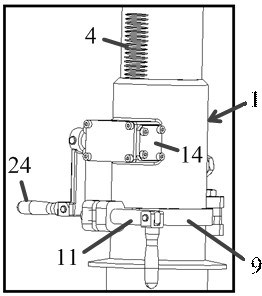

[0052] A machine gun mount for combat helicopters, such as figure 1 and figure 2 shown, it includes:

[0053] A sleeve assembly, including: an inner sleeve 1 and an outer sleeve 2 that are sleeved and connected in a sliding manner and used to adjust the height of the machine gun frame;

[0054] The sleeve driver 3 applies pressure to the inner sleeve 1 and the outer sleeve 2 to keep the two away from each other, thereby raising the machine gun frame; such as figure 2 As shown, the sleeve driving member 3 is a compression spring, which is arranged in the cavity enclosed by the inner sleeve 1 and the outer sleeve 2; the upper end of the compression spring is connected to the inner cavity of the inner sleeve 1 The top surfaces are connected to push the inner sleeve 1 away from the outer sleeve 2 . In addition, the above-mentioned sleeve assembly further includes: a buffer spring base 6, which is provided with a cylindrical boss, and the compression spring is sleeved on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com