Discharge device of stuffed food forming machine

A discharge device and molding machine technology, applied in the direction of manipulators, food science, dough processing, etc., can solve the problems of simple function, complex structure, no further improvement of the discharge device of stuffed food, etc., to achieve stable movement, Strong clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

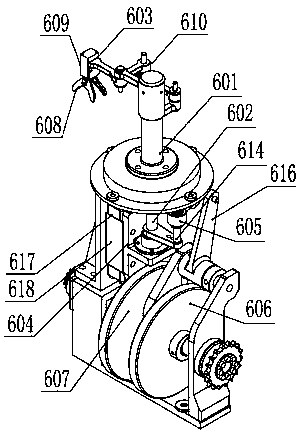

[0030] The discharge device of the stuffed food forming machine includes a rotating seat 601, the middle part of which is connected with a lifting rotating shaft 602, and the top of the rotating seat 601 is provided with a finger chuck 603, and the lifting rotating shaft 602 is connected with the lifting shaft 604 through the mounting seat 604. The sliding block 618 is connected, and the lifting shaft 602 is also sleeved with a sliding sleeve 605 , the sliding sleeve 605 is connected with the swing cam 606 , and the mounting base 604 is connected with the lifting cam 607 . The finger chuck 603 includes a pair of clamping blocks 608 and a finger cylinder 609 for driving the clamping blocks 608 to move.

[0031] The overall movement of the application is stable, the clamping is firm, and the food will not fall or the like.

Embodiment 2

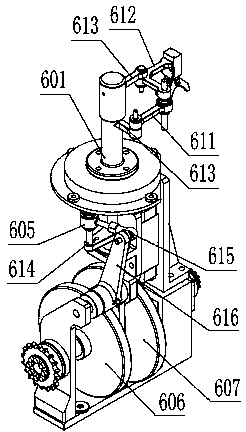

[0033] The discharge device of the stuffed food forming machine includes a rotating seat 601, the middle part of which is connected with a lifting rotating shaft 602, and the top of the rotating seat 601 is provided with a finger chuck 603, and the lifting rotating shaft 602 is connected with the lifting shaft 604 through the mounting seat 604. The sliding block 618 is connected, and the lifting shaft 602 is also sleeved with a sliding sleeve 605 , the sliding sleeve 605 is connected with the swing cam 606 , and the mounting base 604 is connected with the lifting cam 607 . The finger chuck 603 includes a pair of clamping blocks 608 and a finger cylinder 609 for driving the clamping blocks 608 to move. The finger chuck 603 is connected to the rotating seat 601 through a parallel swing link 610, and the parallel swing link 610 includes at least one connecting rod. The parallel swing link 610 includes a connecting rod A611 and a connecting rod B612, the connecting rod B612 is L-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com