PI film transverse drawing machine and track adjusting mechanism

A technology of adjusting mechanism and horizontal drawing machine, which is applied in the field of PI film processing, can solve the problems of asymmetry on both sides and film deviation, and achieve the effect of uniform horizontal drawing and reducing adjustment time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

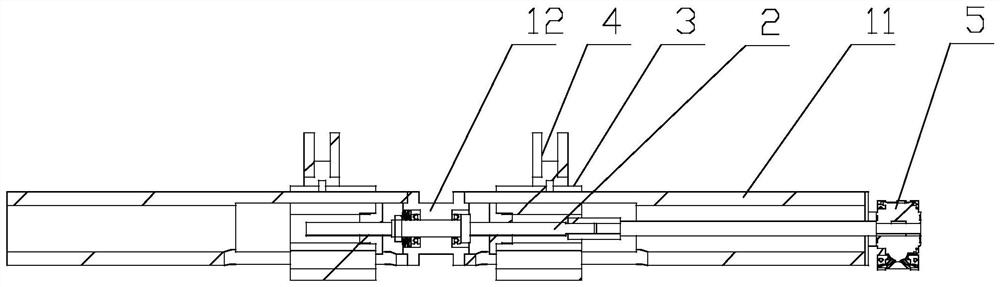

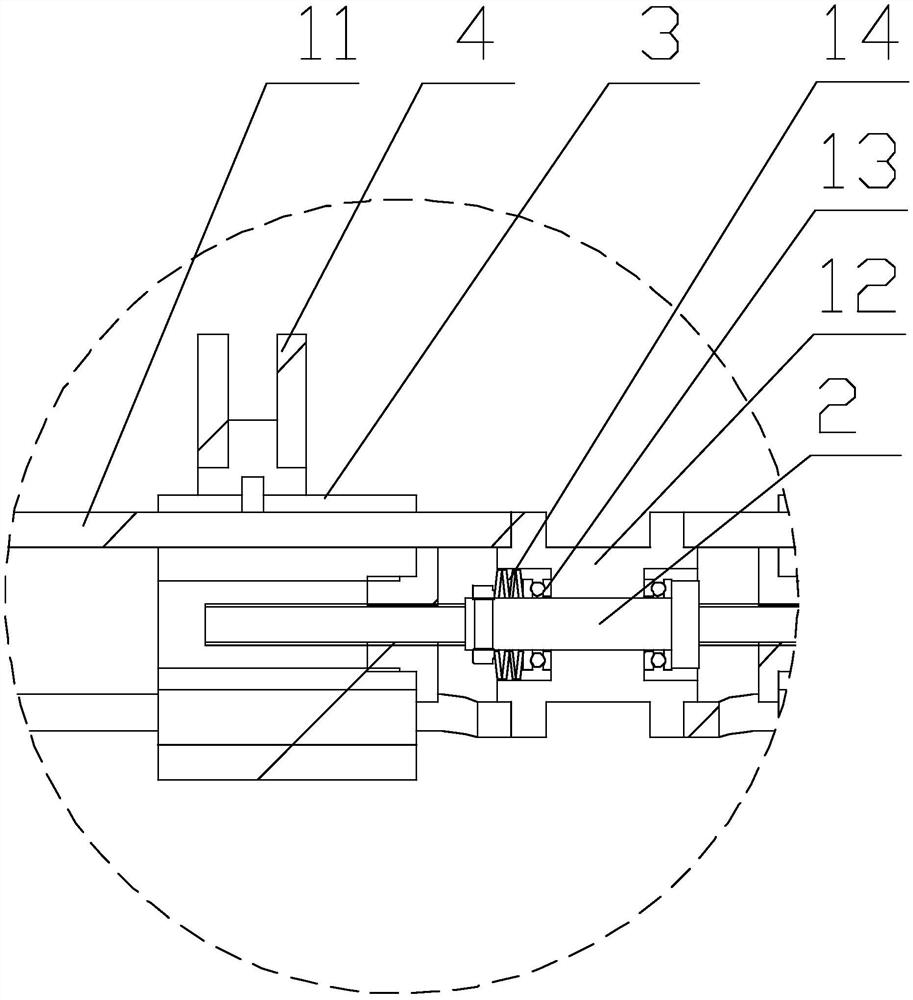

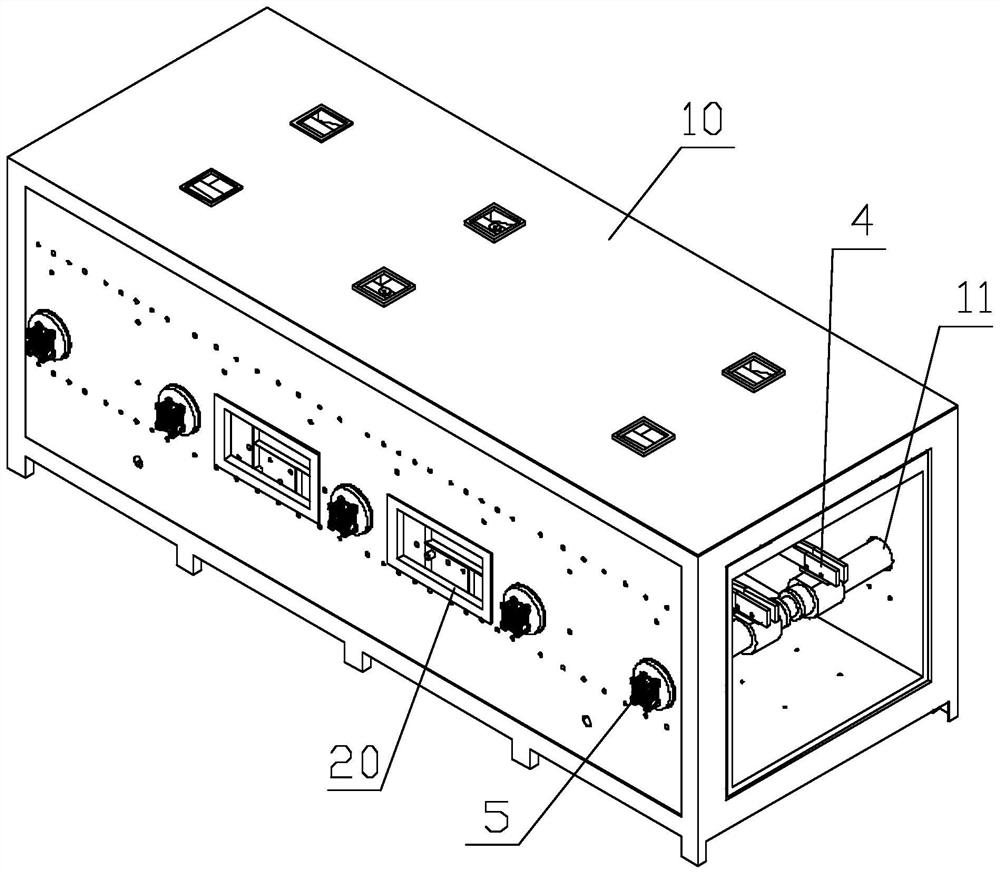

[0023] like Figures 1 to 4 shown, figure 1 It is a schematic structural diagram of a track adjustment mechanism for a PI film cross-drawing machine proposed by the present invention, figure 2 for figure 1 The schematic diagram of the partial structure of the middle bearing seat and the sleeve body, image 3 A schematic diagram of the three-dimensional structure of a PI film cross-drawing machine proposed by the present invention, Figure 4 It is a schematic side view structure diagram of a PI film cross-drawing machine proposed by the present invention.

[0024] refer to figure 1 , a track adjustment mechanism for a PI film cross-drawing machine proposed by the present invention includes: a support assembly, a drive motor 5 and a guide rail 4;

[0025] The support assembly includes a guide sleeve and a lead screw 2. The guide sleeve is installed horizontally in the heating channel and is arranged perpendicular to the extension direction of the heating channel. The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com