Multi-target equipment layout and logistics system design collaborative optimization method and system

A collaborative optimization and logistics system technology, applied in logistics, mechanical equipment, manufacturing computing systems, etc., can solve the problems of low reliability of design schemes, and achieve the effect of real and reliable layout schemes and logistics system design schemes, and accurate logistics distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

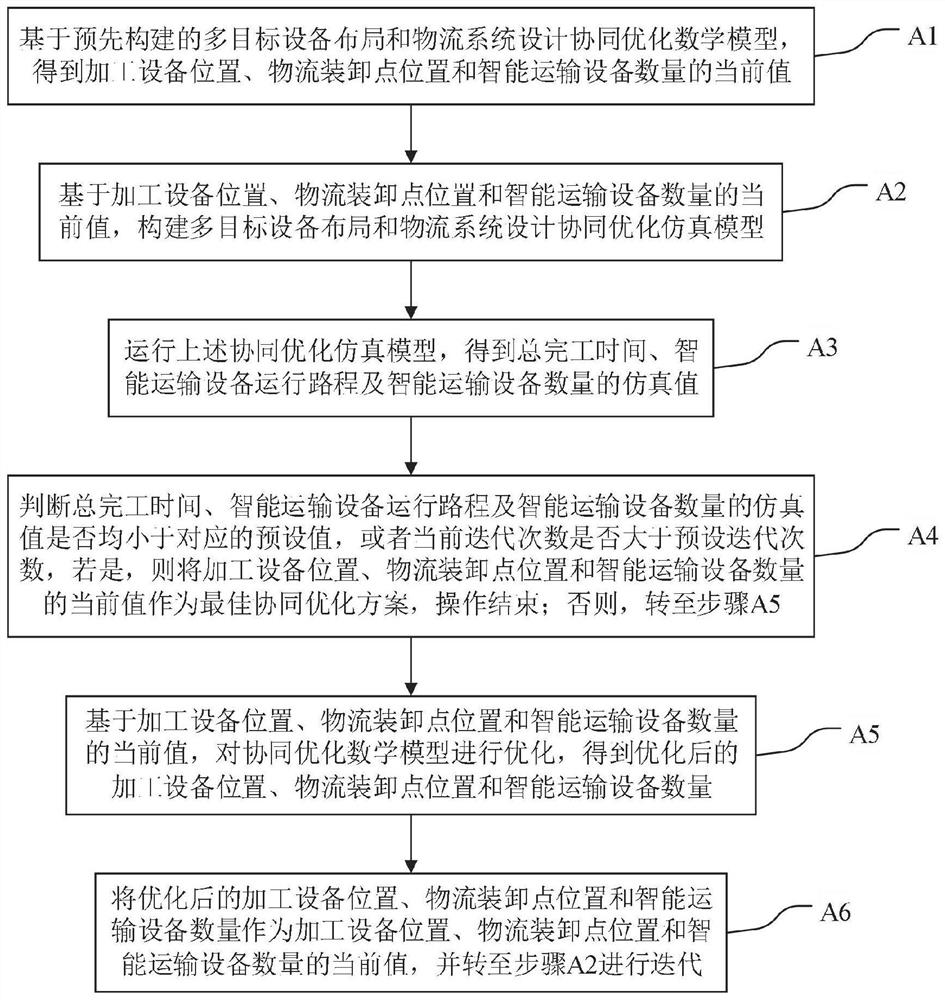

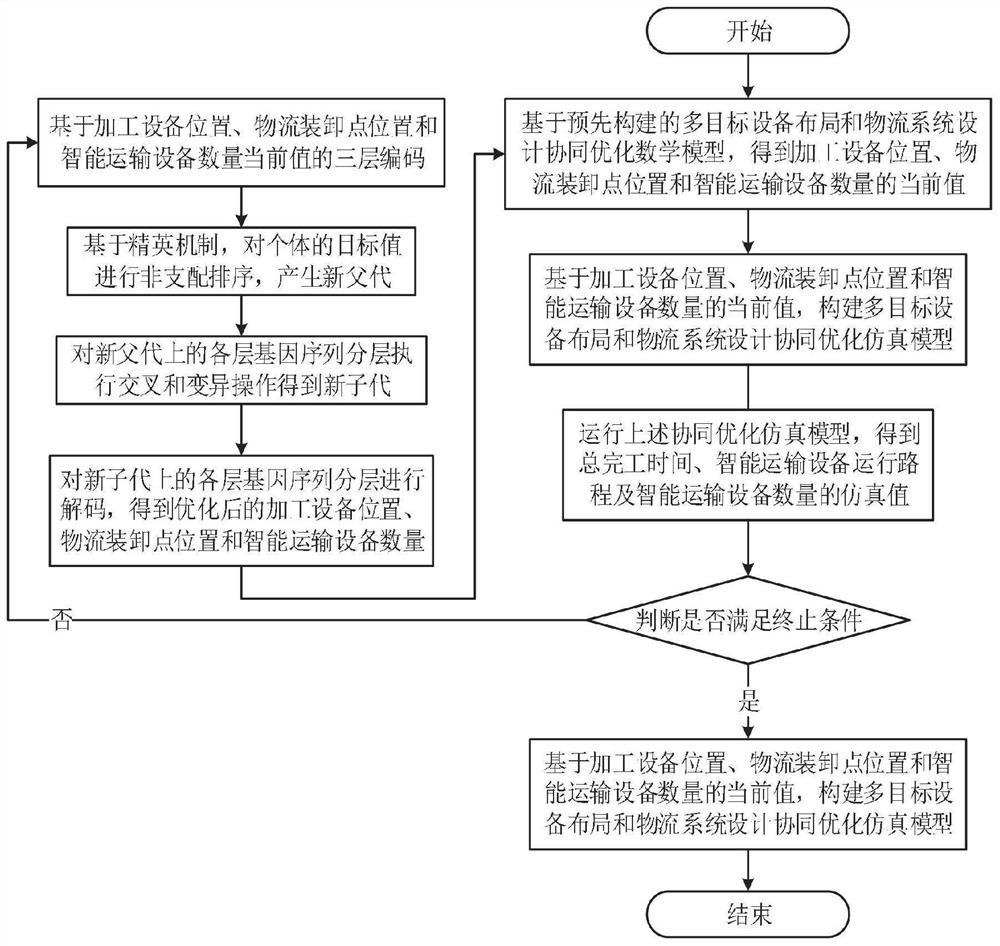

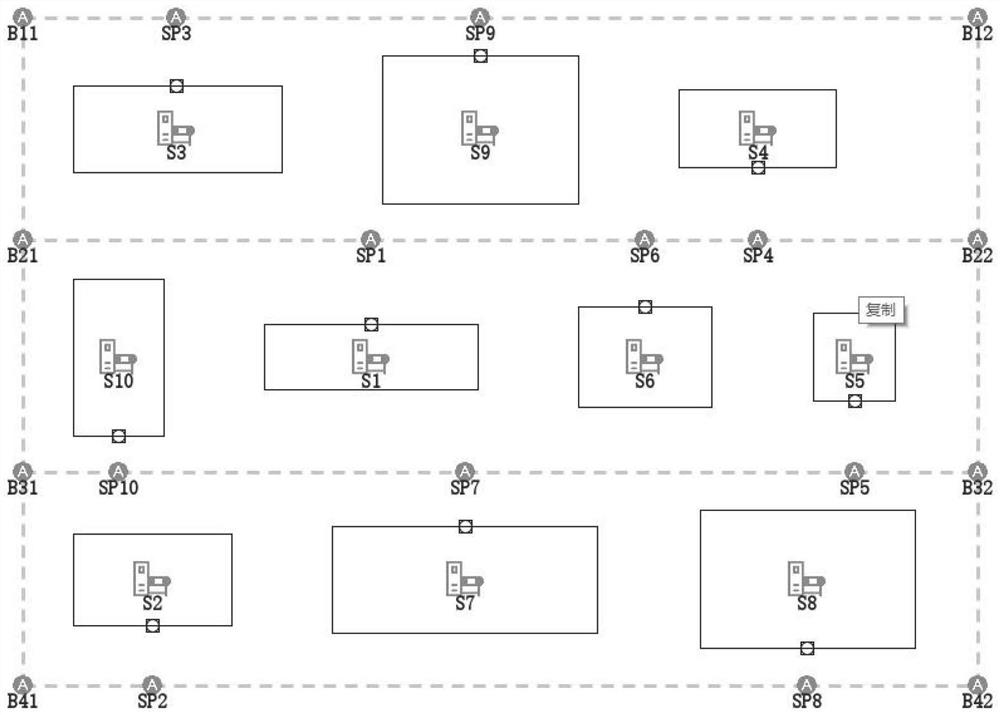

[0115] like figure 1 As shown, this embodiment provides a simulation-based collaborative optimization method for multi-objective equipment layout and logistics system design, such as figure 2 shown, the specific steps are as follows:

[0116] The first part, based on workshop size and processing equipment size, constructs a multi-objective equipment layout and logistics system design collaborative optimization mathematical model aiming at the shortest total completion time, the shortest running distance of intelligent transportation equipment, and the minimum number of intelligent transportation equipment; and based on the constructed The mathematical model of collaborative optimization is obtained to obtain the current value of the position of processing equipment, the position of logistics loading and unloading point and the number of intelligent transportation equipment.

[0117] The second part, based on the current value of the location of processing equipment, the loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com