Minimization method of product inspection total completion time based on sparkr

A completion time and minimization technology, applied in prediction, genetic rules, genetic models, etc., can solve problems such as data volume expansion, achieve convenient call and operation, and optimize the effect of sequencing large-scale test plans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At present, the product testing and testing methods of manufacturing enterprises are mainly based on manual experience, the efficiency is low, and the resource utilization is not sufficient. Moreover, the data volume of product testing and testing tasks continues to expand. The amount of data that can be processed by existing algorithm optimization models is limited by a single machine Large memory capacity makes it impossible to analyze large-scale data. Although the product scheduling method based on Hadoop enables users to process big data, it does not consider the cluster problem, which is not conducive to the scalability of the algorithm model, and the data statistics and analysis capabilities are insufficient. .

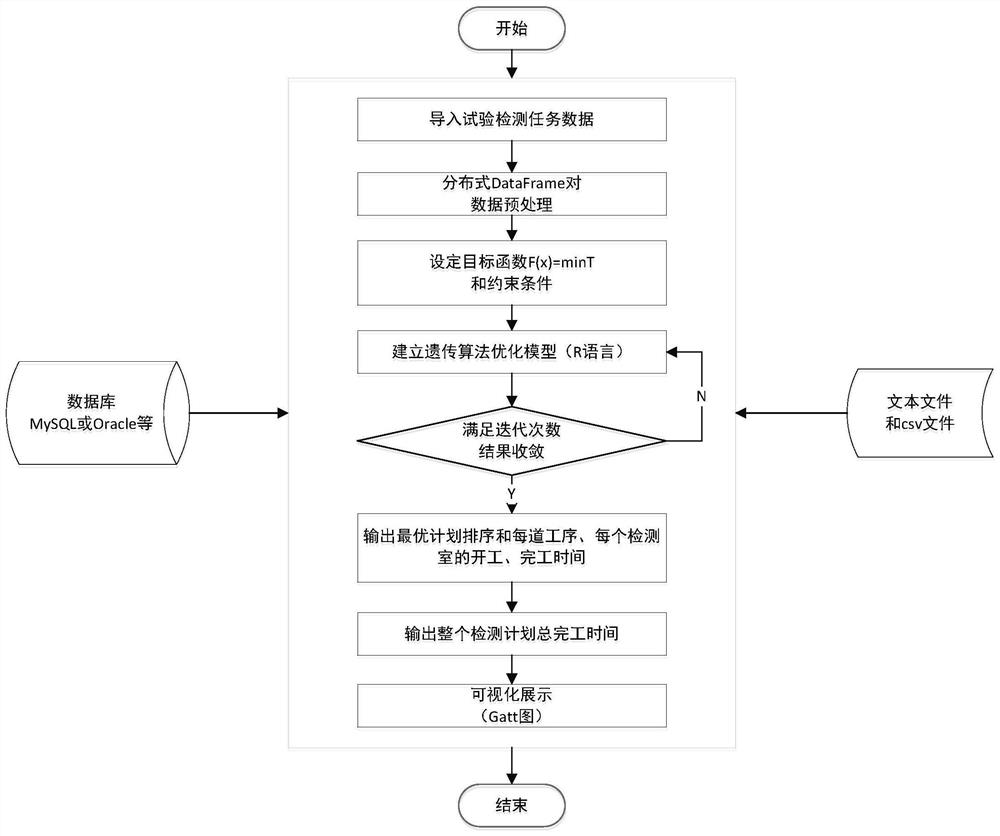

[0030]The present invention proposes a method for minimizing the total completion time of product testing plans based on SparkR, aiming at the optimization problems urgently needed to be solved in the existing product test detection and sorting methods, t...

Embodiment 2

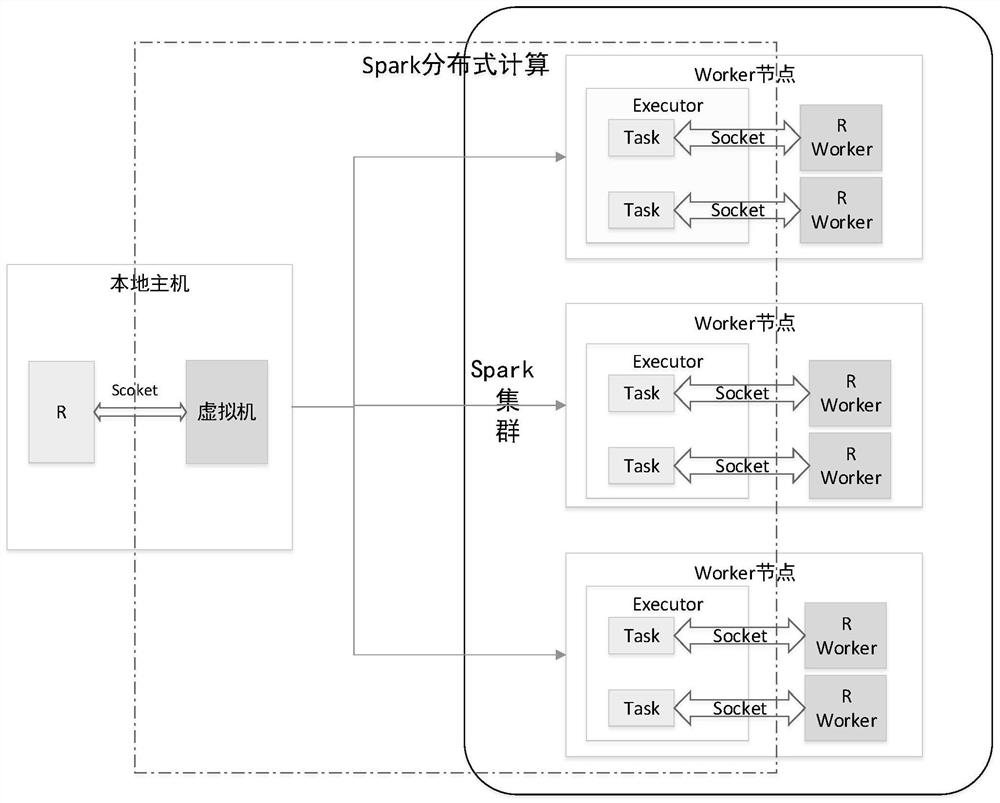

[0040] The total completion time minimization method of the product test detection plan based on SparkR is the same as embodiment 1, and the DataFrame described in step (2) of the present invention is a two-dimensional data.frame similar to R created for storing product test detection task data Table, use the schema to represent the name and data type of the product test plan task data column. All the test test task data in the DataFrame are stored in the data type of the JVM. The implementation of a DataFrame method is simply to call the DataFrame on the JVM side. The data processing method directly calls and preprocesses the test detection task data stored in the DataFrame through the R program. The DataFrame API also includes a part of the RDD API. It is necessary to convert the DataFrame into an RDD first, and then call the data grouping, aggregation, and repartition operations of the RDD. In this case, it is necessary to start the R Worker process to perform distributed co...

Embodiment 3

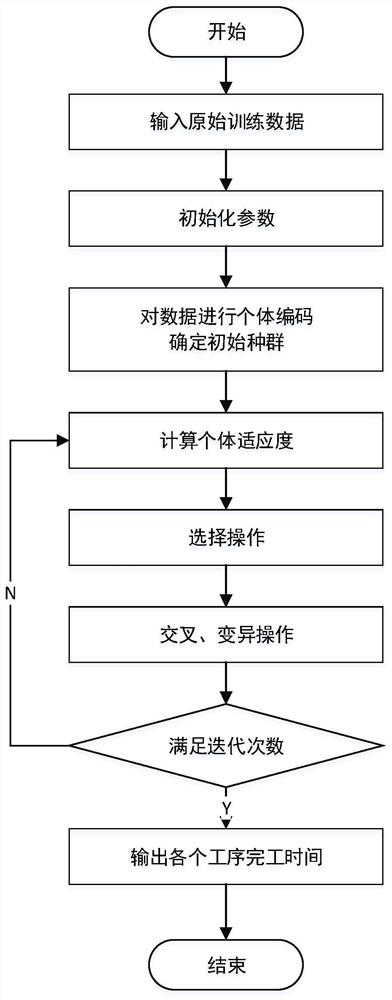

[0043] The total completion time minimization method of the product test detection plan based on SparkR is the same as embodiment 1-2, the mathematical model of determining the test detection task objective function and constraint conditions in the step (3) of the present invention, and the test detection plan scheduling problem includes determining each detection The sequence of inspections on the laboratory and the constraints to be satisfied by the test and inspection tasks in the test plan scheduling problem, where the constraints specifically include:

[0044] (3.1) Each test task consists of several test products, and each test product is tested in different testing rooms. Each test room can only test one test product at the same time, and each test product is Only one test room can be tested at a time. In the present invention, the test product is referred to as product for short.

[0045] (3.2) Each test product must be tested in the testing room designated by the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com