Galvanized steel sheet having excellent fatigue strength in resistance spot welding portion, and method for manufacturing same

A technology for galvanized steel sheets and steel sheets, which is applied in hot-dip galvanizing, coating, metal material coating processes, etc., can solve the problems of reduced fatigue strength, poor spot weldability, and obstacles to high-strength steel sheets, and eliminates Tensile stress, reduction in number and length of generation, excellent effect on fatigue strength

Pending Publication Date: 2022-07-12

POSCO

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, when galvanizing the surface of a high-strength steel sheet, there is a problem that spot weldability deteriorates

That is, in the case of high-strength steel, the tensile strength is high and the yield strength is also high, so it is difficult to eliminate the tensile stress generated during welding by plastic deformation, so there is a high possibility of microcr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

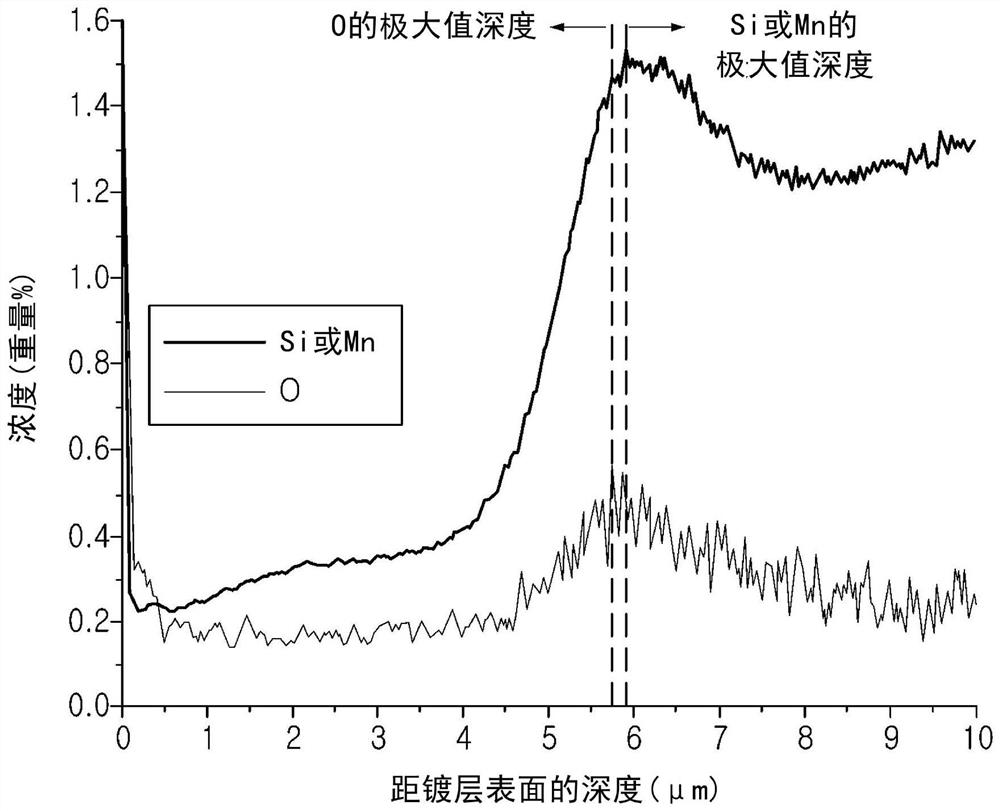

The present invention relates to a galvanized steel sheet having excellent fatigue strength in a resistance spot welding portion, and a method for manufacturing the same. A galvanized steel sheet according to one aspect of the present invention may include a base steel sheet and a zinc-based plating layer formed on a surface of the base steel sheet, in which a concentration distribution of oxygen and one or both of silicon and manganese measured in a depth direction from the surface of the base steel sheet may have a form showing a maximum point in the depth direction from the surface, the absolute value of the difference between the depth at which the maximum of the concentration distribution of oxygen is formed and the depth at which the maximum of the concentration distribution of one of silicon and manganese is formed may be 0.5 [mu] m or less.

Description

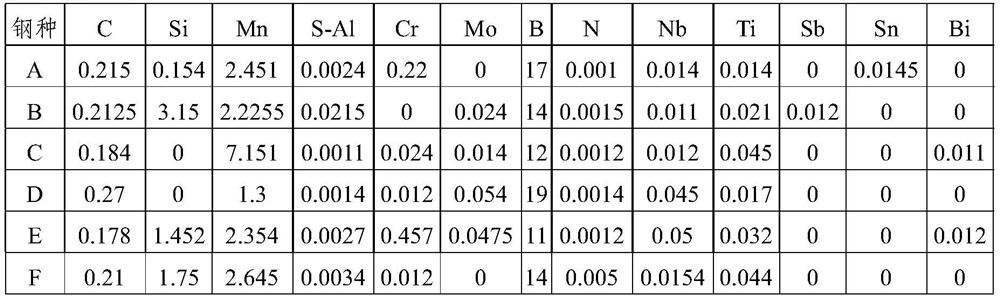

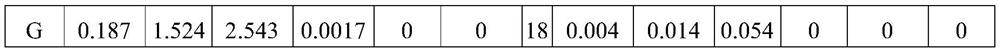

technical field [0001] The present invention relates to a galvanized steel sheet excellent in fatigue strength of a resistance spot welded portion and a method for producing the same. Background technique [0002] Due to problems such as environmental pollution, the control of vehicle exhaust and fuel efficiency is increasingly strengthened. Therefore, the demand for reducing fuel consumption by reducing the weight of automobile steel sheets is increasing, and thus various high-strength steel sheets with high strength per unit thickness have been developed and launched. [0003] High-strength steel generally refers to steel with a strength of 490 MPa or more, but it is not necessarily limited to this, transformation-induced plasticity (TRIP) steel, twin-induced plasticity (TWIP) steel, dual-phase (Dual Phase, DP) steel, complex phase (Complex Phase, CP) steel, etc. may belong to high-strength steel. [0004] In addition, automotive steel is supplied in the form of a plated...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C2/06C23C2/28C23C2/02C23C2/40C22C38/38C22C38/34C22C38/04C22C38/02C22C38/00C22C38/28

CPCC23C2/02C22C38/04C23C2/06C23C2/28C22C38/38C22C38/02C22C38/14C22C38/28C23C2/40B32B15/013C22C38/32C22C38/22C22C38/26C22C38/60C22C38/008C22C38/12C23C30/00C23C28/023C23C28/025C23C2/024C23C2/022C22C38/34C22C38/001C23C2/29B32B2307/718C21D6/002C21D6/005C21D6/008C21D8/0205C21D8/0226C21D8/0236C21D8/0273C21D9/46C22C38/002C22C38/06

Inventor 姜己哲李正焕

Owner POSCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com