Variable cross-section frame beam

A frame beam and variable cross-section technology, applied in the direction of joists, girders, truss beams, etc., can solve the problem of large space height, and achieve the effect of reducing height, lowering floor height, and reducing calculation span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

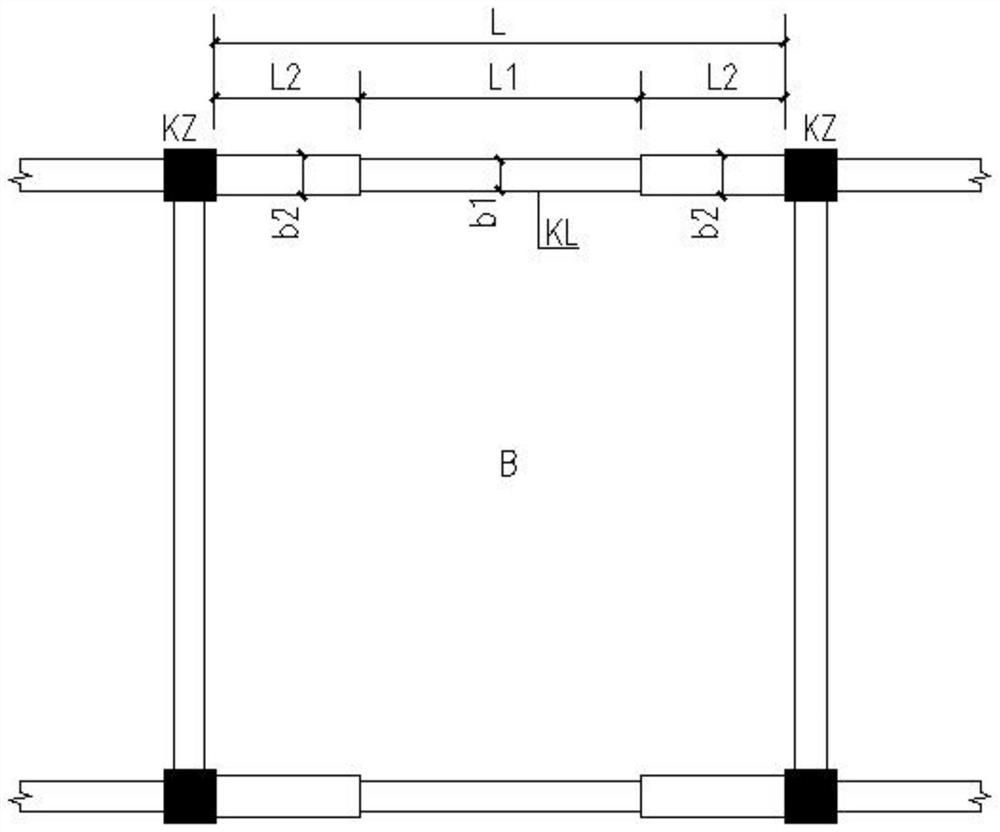

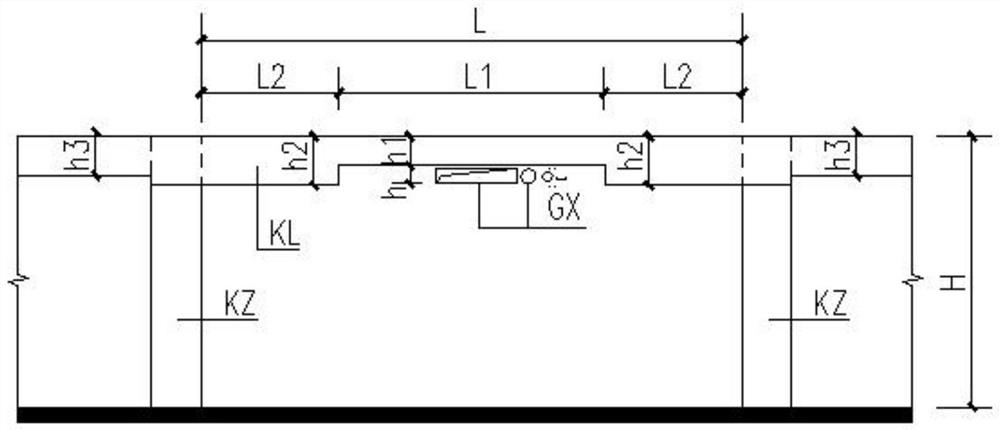

[0024] see Figure 1-2 , the variable cross-section frame beam is composed of a mid-span structural beam and a bearing segment structural beam.

[0025] According to the existing technical conditions of a building, the structural beam height is 0.8 meters, the beam width is 0.3 meters, and the pipeline height at the intersection is 0.2 meters. According to the existing technical solution, the building floor height = 2.2 (clear height requirement) + 0.8 (beam height) + 0.2 (pipeline height) + 0.2 (installation height) = 3.4 meters.

[0026] use figure 1 The variable section frame beam shown: the height of the structural beam in the mid-span section is 0.5 m and the width of 0.3 m, and the height of the structural beam in the support section is 0.9 m and the width is 0.5 m. The required building floor height at the intersection = 2.2 (clear height requirement) + 0.5 (beam height) + 0.2 (pipeline height) + 0.2 (installation height) = 3.1 meters, and the required building floor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com