Safe overflow device of condensate water collecting tank

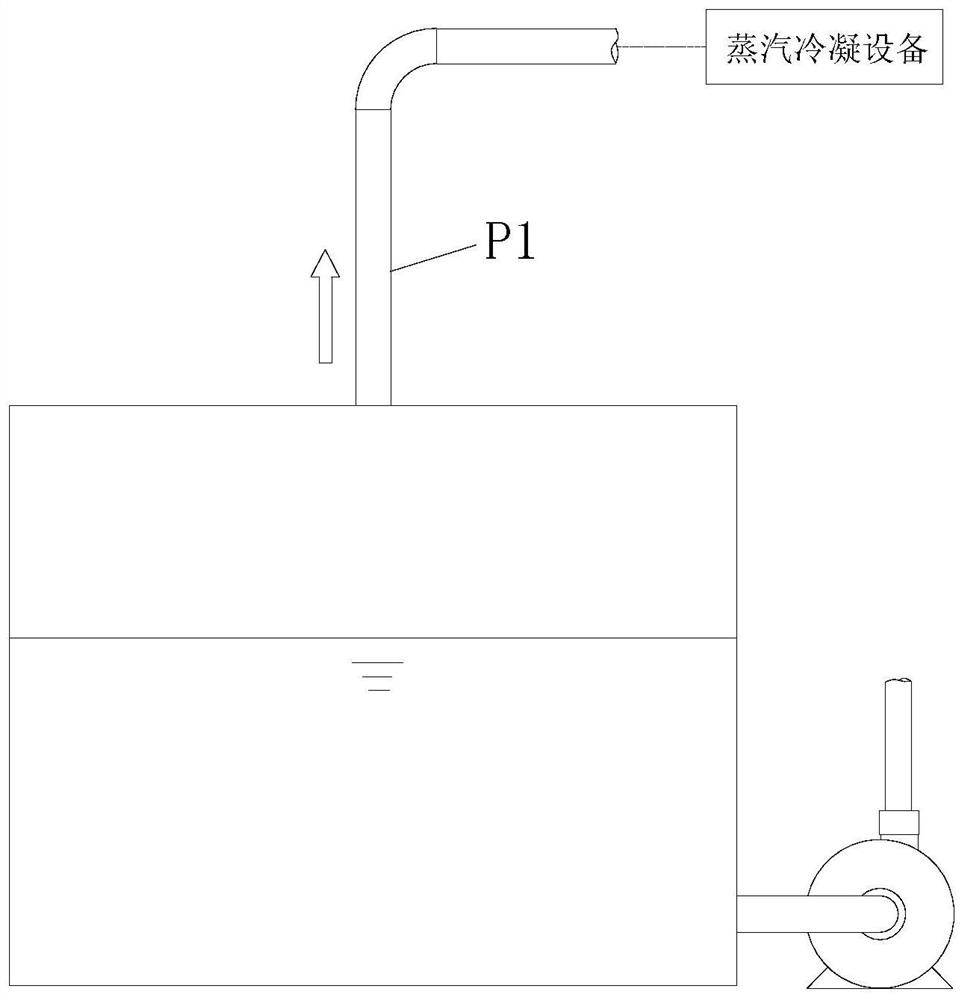

A technology of overflow device and condensate tank, which is applied in steam/steam condensers, sealing devices of heat exchangers, lighting and heating equipment, etc., can solve the problems of pressure rise at P1 of the pipeline and damage to steam condensing equipment, etc., to ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

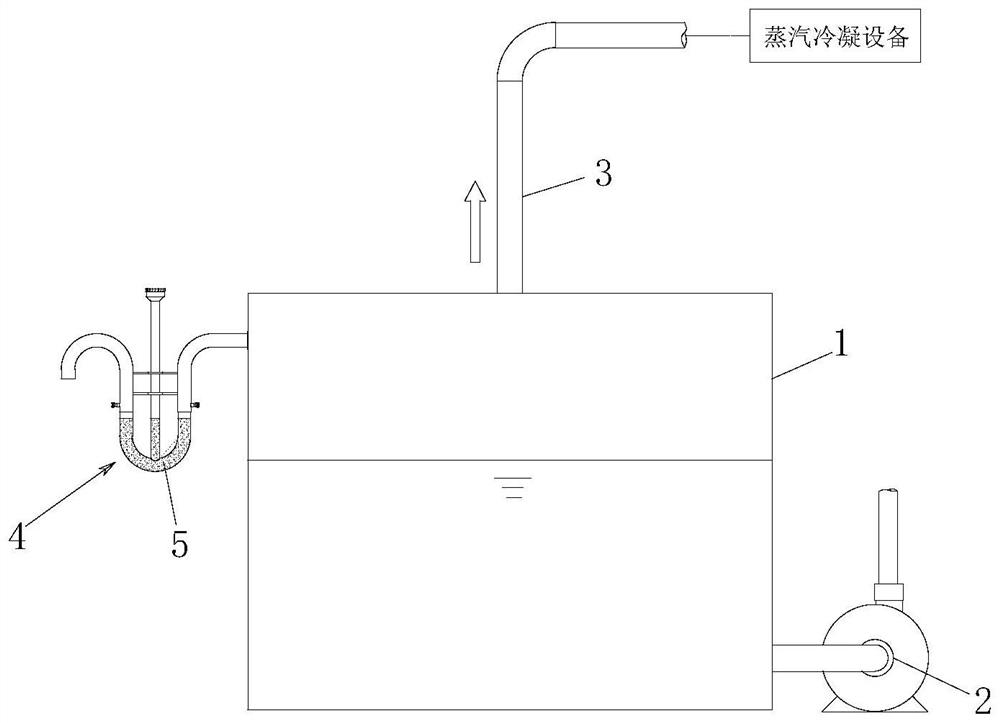

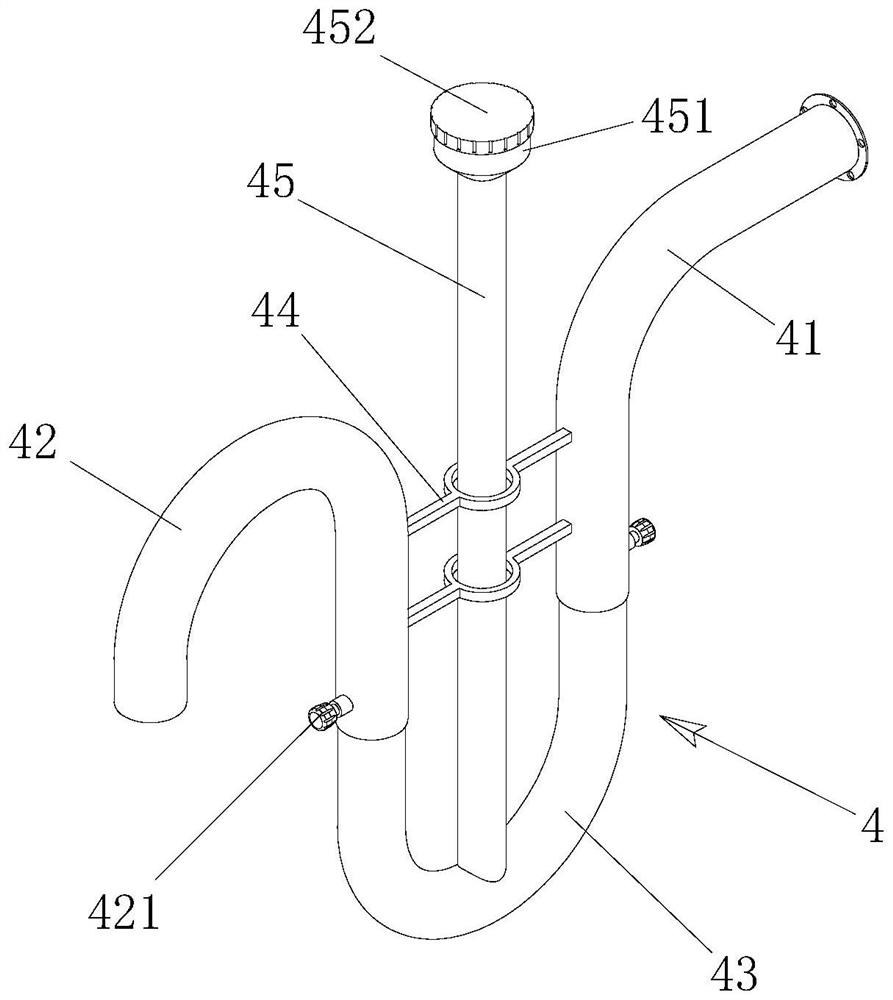

[0031] refer to Figure 2-5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the overflow pipe 4 adopts a U-shaped pipe with adjustable depth, and the overflow pipe 4 includes a connecting pipe section 41 , a U-shaped pipe section 42 and an overflow pipe section 43 , the connecting pipe section 41 and the overflow pipe section 43 are arranged at the same height on both sides of the U-shaped pipe section 42 in a way of plugging, and a fixing frame 44 is arranged between the connecting pipe section 41 and the overflow pipe section 43, and the fixing frame 44 will connect the pipe section 41 and the overflow pipe section. 43 is fixed, on the one hand, it can ensure that the connecting pipe section 41 and the overflow pipe section 43 are always in the same height state, and on the other hand, the U-shaped pipe section 42 can be adjusted up and down. One end of the connecting pipe section 41 away from the U-shaped pipe section 42 ...

Embodiment 3

[0033] refer to Figure 2-5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 or 2 is that the "U"-shaped bottom end of the overflow pipe 4 is connected with a water injection pipe 45, and the top of the water injection pipe 45 is provided with a water injection port 451, The water injection port 451 is in the shape of a funnel, and the water injection port 451 is provided with a cover 452 . After the liquid sealing area 5 is discharged from the overflow pipe 4 and the steam discharge of the steam pipe 3 is normal again, the water injection pipe 45 is provided for adding plugging liquid to form the liquid sealing area 5 again. The water injection pipe 45 is a transparent pipe, so as to facilitate the observation of the amount of the plugging liquid added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com