Tunnel section convergence deformation quantitative calculation method based on high-density measuring point strain

A technology of convergent deformation and quantitative calculation, applied in measurement devices, neural learning methods, complex mathematical operations, etc., can solve the problem that the distributed sensing optical cable cannot be laid along the section closed, the deformation calculation result error, and the additional level cannot be considered. Convergence deformation and other problems, to achieve the effect of improving computational accuracy, computational efficiency, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

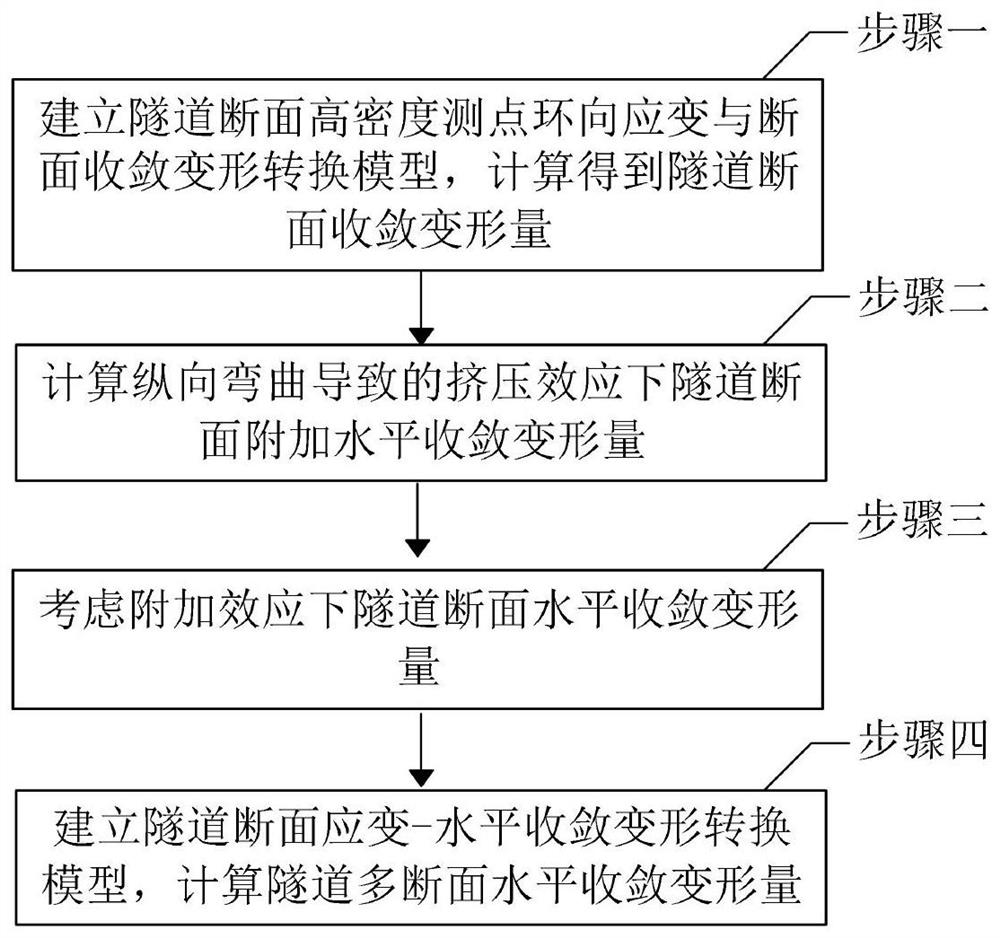

[0023] Embodiment 1: This embodiment describes a quantitative calculation method for tunnel section convergence deformation based on high-density measuring point strain, and the method includes the following steps:

[0024] Step 1: Use the hoop strain monitoring data of the high-density measurement points of the tunnel section obtained by the fully distributed optical fiber sensor to construct a ring-shaped curved beam model of the tunnel section based on the conjugate curved beam theory, and establish the relationship between the hoop strain of the high-density measurement points of the tunnel section The section convergence deformation transformation model is used to calculate the convergence deformation of the tunnel section;

[0025] Step 2: Build the basic structure of the calculation force method for the additional horizontal convergence deformation of the tunnel section, and calculate the additional horizontal convergence deformation of the section caused by the longitud...

Example Embodiment

[0029] Embodiment 2: The method for quantitatively calculating the convergence deformation of tunnel section based on the strain of high-density measuring points described in Embodiment 1, in step 1, the calculation method for the amount of convergence deformation of the tunnel section is:

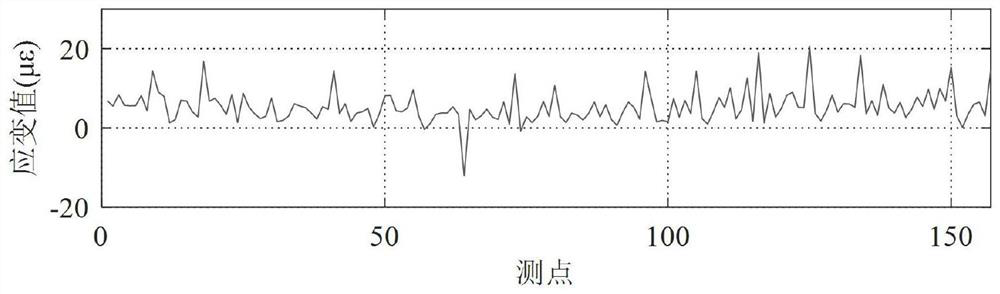

[0030] (1) Using the fully distributed sensing optical cable laid along the ring length of the tunnel section, the strain monitoring data of high-density measuring points are collected and obtained. Convergence deformation to arbitrary position coordinates (p,λ) (p=1,2,...,n; 0≤λ<1), namely

[0031]

[0032] In the formula, Represents the convergence deformation at the azimuthal coordinates (p, λ) caused by the bending moment; β represents the central angle corresponding to the two circumferential strain points of the optical fiber; R represents the radius of the tunnel section segment; h represents the height of the tunnel section segment ; Represents the hoop strain of the section...

Example Embodiment

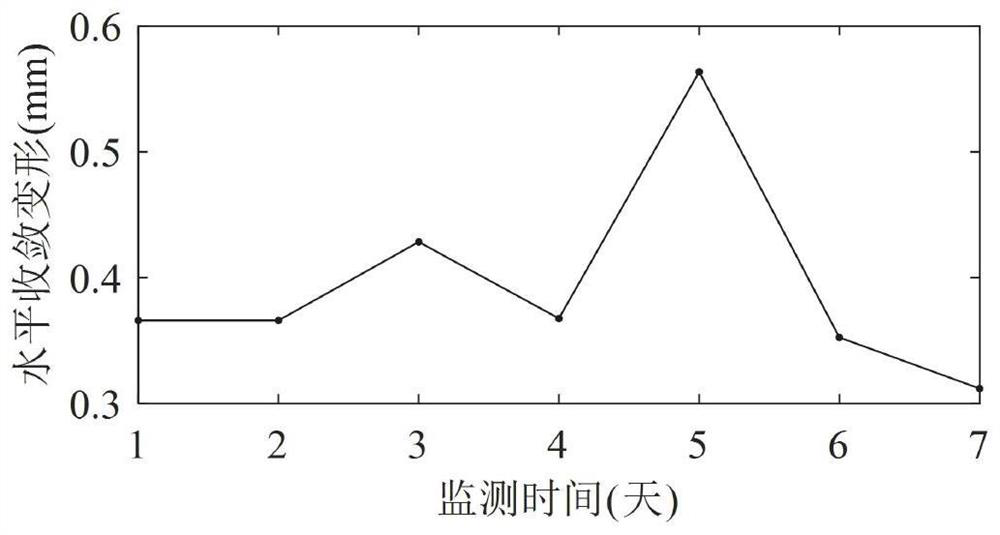

[0039] Embodiment 3: In the method for quantitatively calculating the convergence deformation of tunnel section based on high-density measuring point strain according to Embodiment 1, in step 2, the calculation method for the additional horizontal convergence deformation of tunnel section under the extrusion effect is:

[0040] (1) The additional horizontal convergence deformation of the section caused by the extrusion effect is affected by the thickness of the segment, the radius of the segment, the moment of inertia of the segment and the longitudinal bending curvature of the tunnel. According to the mechanism of the extrusion effect caused by the longitudinal bending, the connection stiffness of the section is considered. The additional horizontal convergence deformation of the section under the extrusion effect is calculated by the following formula, namely

[0041]

[0042] In the formula, represents the additional horizontal convergence deformation of the tunnel sect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap