Stator automatic winding and embedding shaping machine of synchronous motor

A technology for synchronous motors and shaping machines, which is applied in the direction of electric components, manufacturing motor generators, manufacturing stator/rotor bodies, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

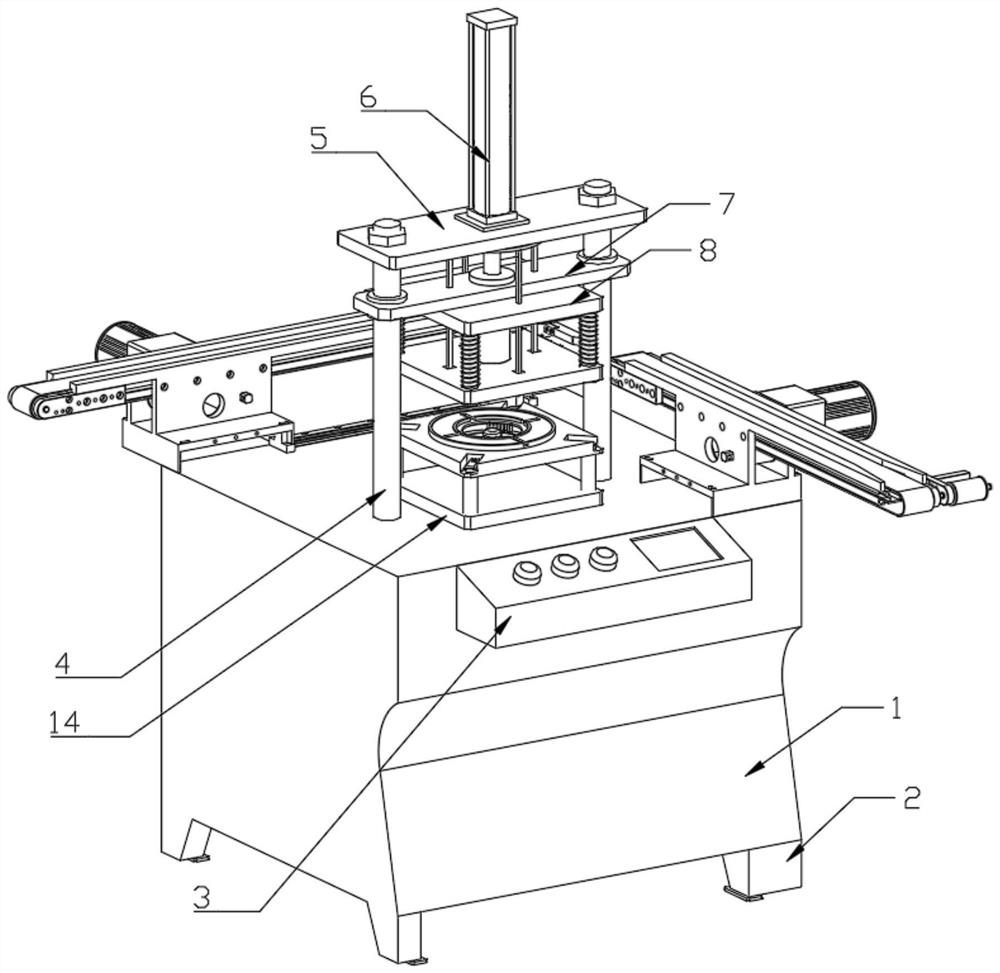

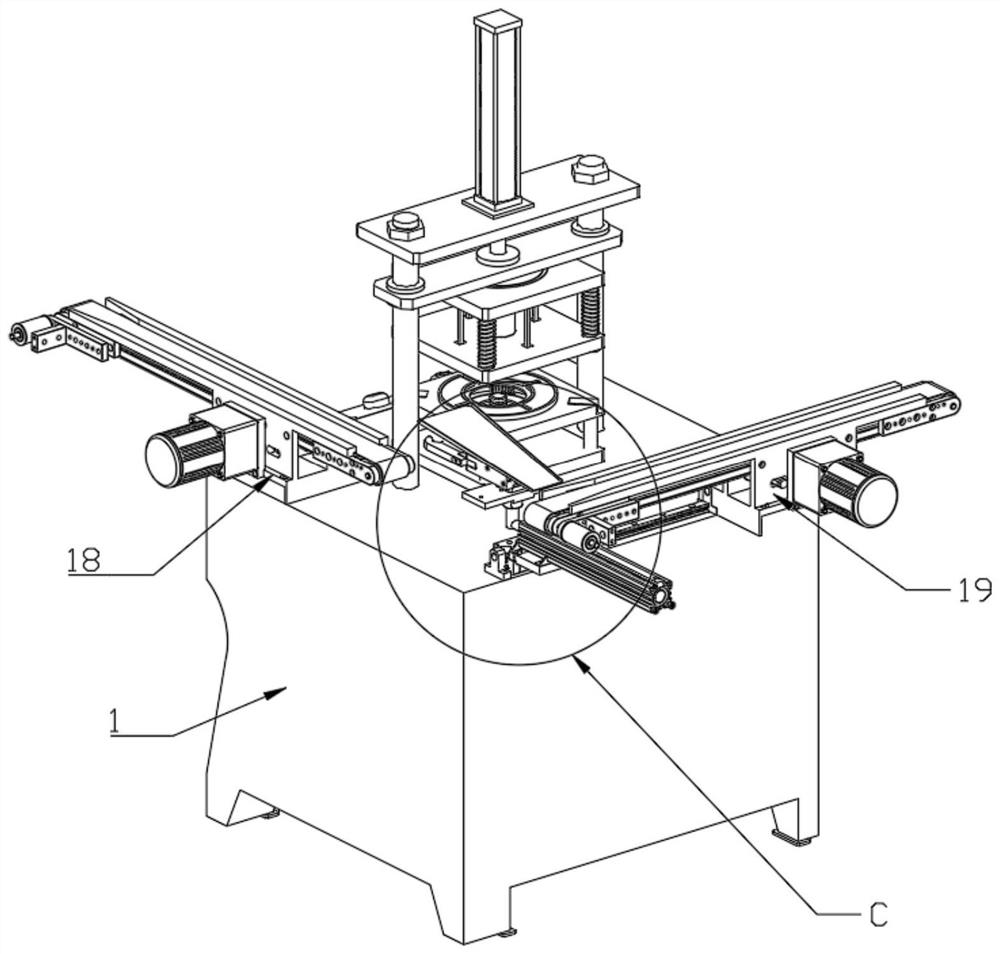

[0032] like Figure 1-Figure 7 As shown in the figure, the present invention provides an automatic winding and shaping machine for the stator of a synchronous motor, including a body 1, a base 2 is arranged on the walls around the bottom of the body 1, a controller 3 is arranged on the upper wall at the front end of the body 1, and the body 1 The top is symmetrically provided with two guide columns 4, the top of the two guide columns 4 is provided with a top plate 5, the top center of the top plate 5 is provided with a first cylinder 6, and the two guide columns 4 are located below the top plate 5 with a mounting plate 7 , the bottom of the mounting plate 7 is provided with a first fixed plate 8, the bottom of the first fixed plate 8 is provided with a first fixed shaft 9, the bottom of the first fixed shaft 9 is provided with a first limit block 10, and the first fixed shaft 9 is provided with A first pressing plate 11 is provided, a connecting ring 12 is arranged above the f...

Embodiment 2

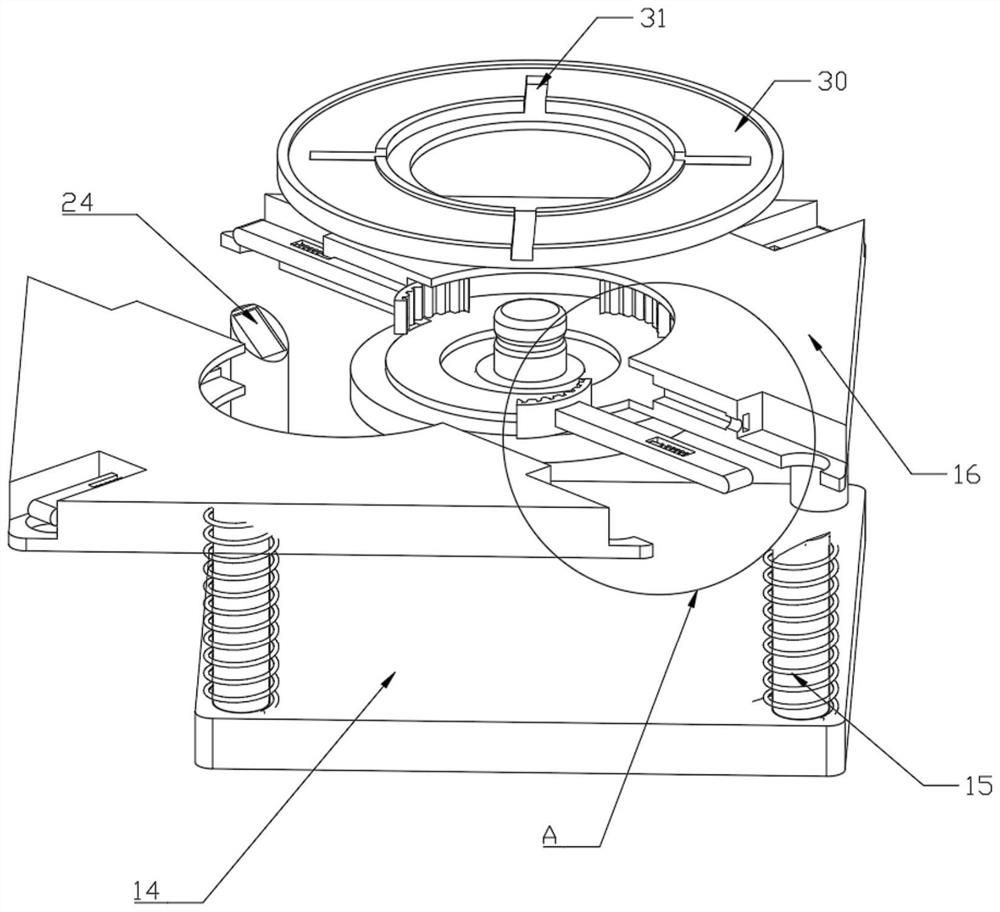

[0034]The bottom of the second fixed shaft 15 is fixedly installed on the top side of the second fixed plate 14 , the top of the second fixed shaft 15 is provided with a first chute 24 , the shaft body of the second fixed shaft 15 is sleeved with a compression spring, and the second pressure plate 16 The second fixing shaft 15 is inserted through the through holes of the outer side wall. The top of the second fixing shaft 15 is fixedly mounted with a third limiting block 30 . The top of the third limiting block 30 is provided with a number of limiting grooves 31 . A shaping groove 25 is formed at the center of the top of the second pressure plate 16 , a plurality of expansion grooves 26 are formed on the inner side of the shaping groove 25 , a second limit block 27 is fixedly installed on one side of the expansion groove 26 , and a mounting groove 28 is formed on one side of the connecting rod 17 , a first fixing rod 29 is fixedly installed between the inner walls of the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com