Screening type grinding device for ceramic valve element material production

A technology of sieving and grinding, ceramic valve core, applied in the direction of grain processing, etc., can solve the problems of leaving solid particles, failing to meet the melting processing standard, unable to crush and process raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

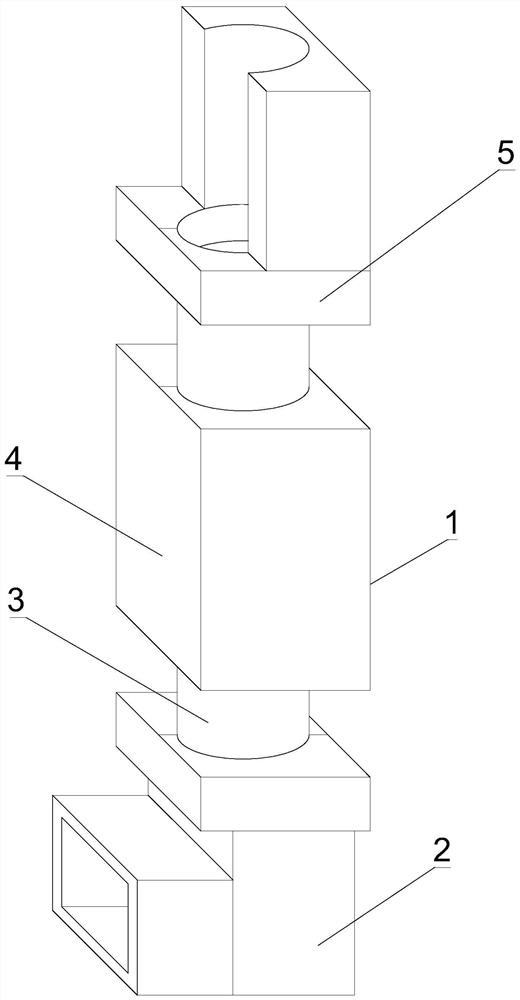

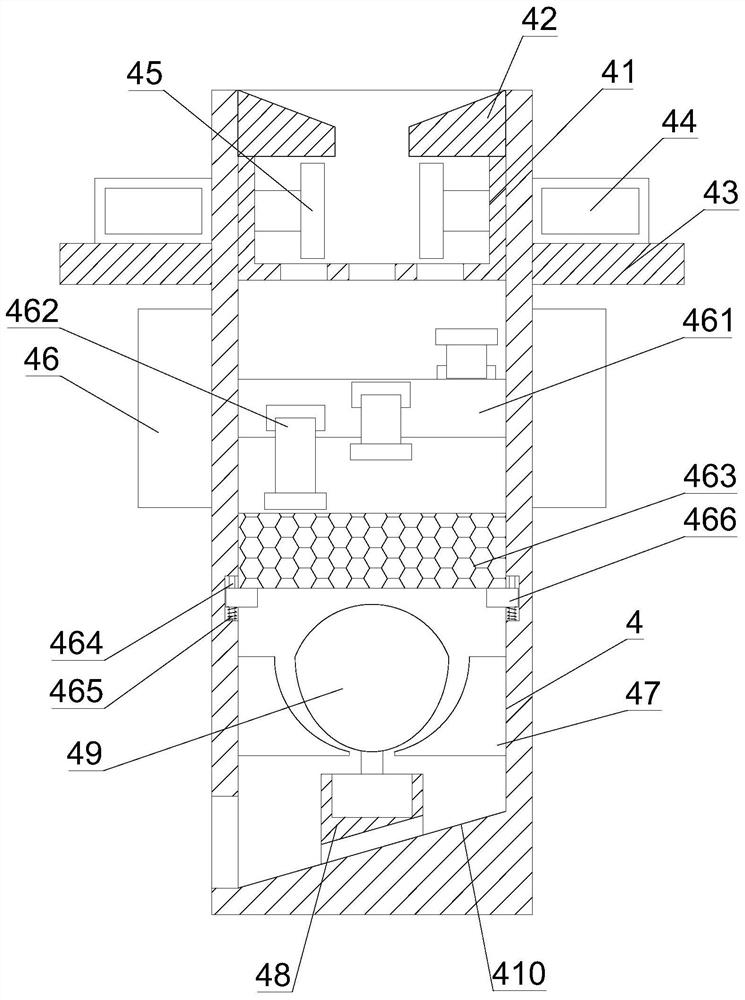

[0041] like Figure 1-10 As shown, the present invention provides a screening type grinding device for the production of ceramic valve core materials, including a ceramic material screening and grinding device 1, and the ceramic material screening and grinding device 1 includes a foot guide port 2, and the foot guide The top outer surface of the material port 2 is provided with a conveying pipe 3, the top of the conveying pipe 3 is detachably installed with a screening grinder 4, and the top of the screening grinder 4 is detachably installed with a feeding port 5, which is used for screening. A rotator 46 is detachably mounted on the upper outer surface of the upper middle of the two sides of the grinder 4. The rotator 46 includes an impact hammer 462. A rotating stick 461 is detachably installed on the output end of the device 46, a material guide inclined plate 410 is provided on the inner surface of the bottom end of the screening grinder 4, and a base shell is detachably i...

Embodiment 2

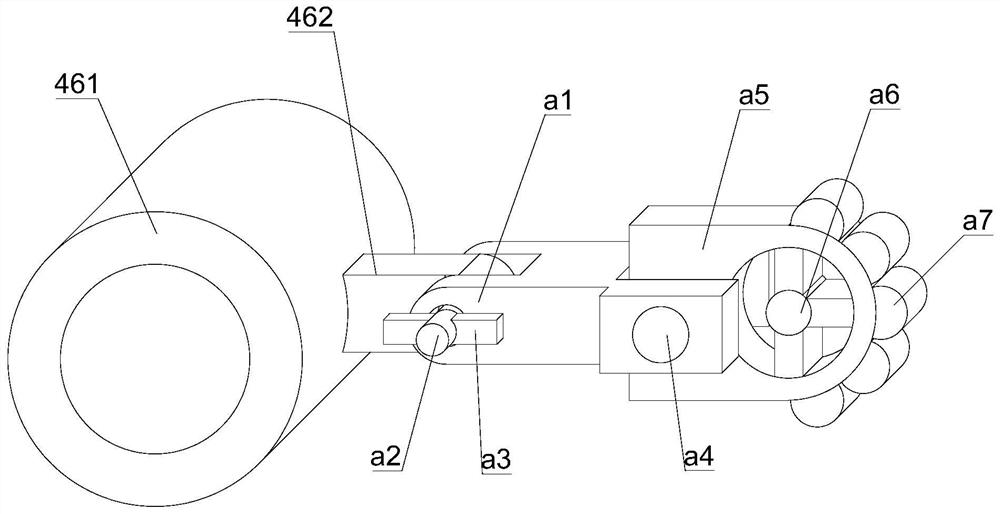

[0044] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, an H-type clamping block a1 is connected to one end of the impact hammer 462 by clamping, and the outer surface of the H-type clamping block a1 is One end of the impact hammer 462 is interspersed with a latch rod a2, the outer surfaces of both ends of the latch rod a2 are detachably connected with a clamping rod a3, and the right end of the H-shaped clamping block a1 is clamped with a counterweight a5. , One end of the H-type clamping block a1 and the outer surface of the counterweight block a5 are interspersed and clamped with a rotating shaft a4, one end of the counterweight block a5 is provided with a circular hollow groove on the outer surface, and the inner surface of the circular hollow groove is provided with There is a shock absorber a6, and a crushing impact head a7 is detachably installed on the outer surface of the right side of the count...

Embodiment 3

[0047] like Figure 1-10 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the grinder 49 includes a protective layer 491, the outer surface of the protective layer 491 is provided with an arc-shaped strip 492, and the outer surface of the arc-shaped strip 492 is provided. An elastic block 493 is provided on the surface, and a grinding trapezoidal block 494 is provided on the outer surface of the arc bar 492 .

[0048] In this embodiment, when encountering a large mineral stone, the elastic block 493 is used to elastically buffer one end of the arc-shaped bar 492, and the reverse elastic force of the elastic block 493 is used to increase the grinding trapezoidal block 494 to impact the granular mineral stone. , to increase the crushing efficiency of the mineral stone, so as to achieve the effect of grinding and crushing the crushed particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com