A device for digging ditches in farmland

A technology for farmland and ditching machines, which is applied in the fields of digging/covering ditches, agriculture, planting methods, etc. It can solve the problems of causing accidents, affecting the appearance, affecting the seed growth environment, etc., and achieves the goal of fully crushing and improving the growth environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

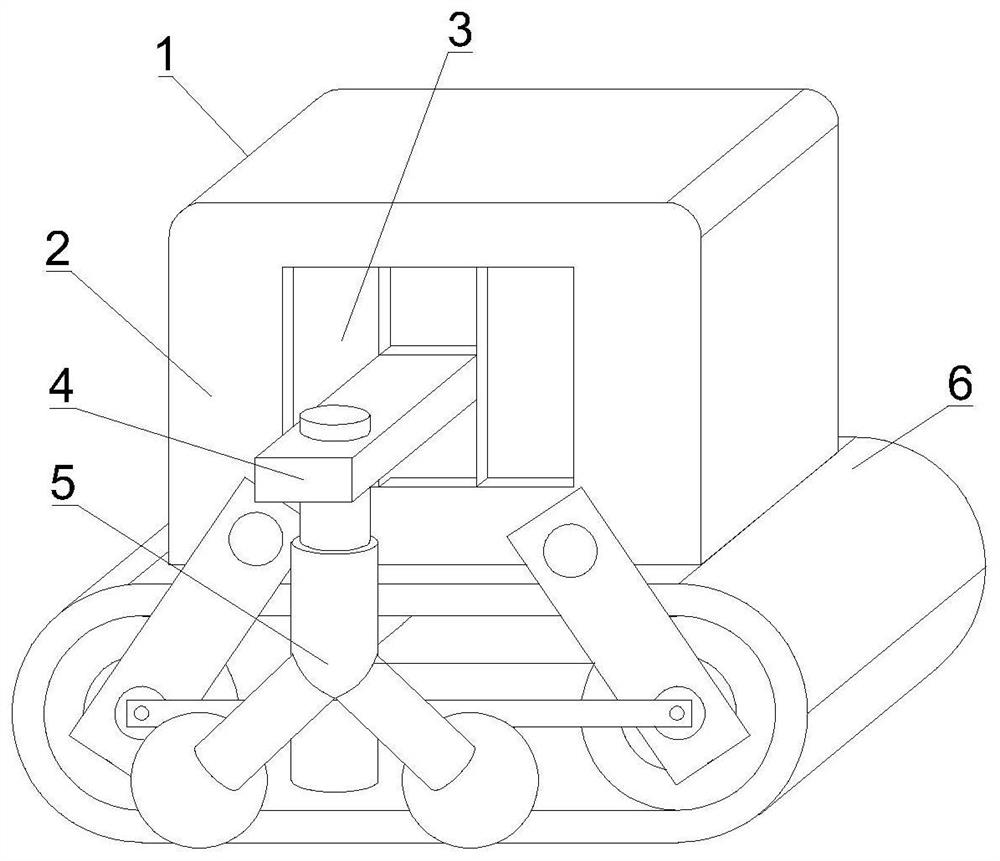

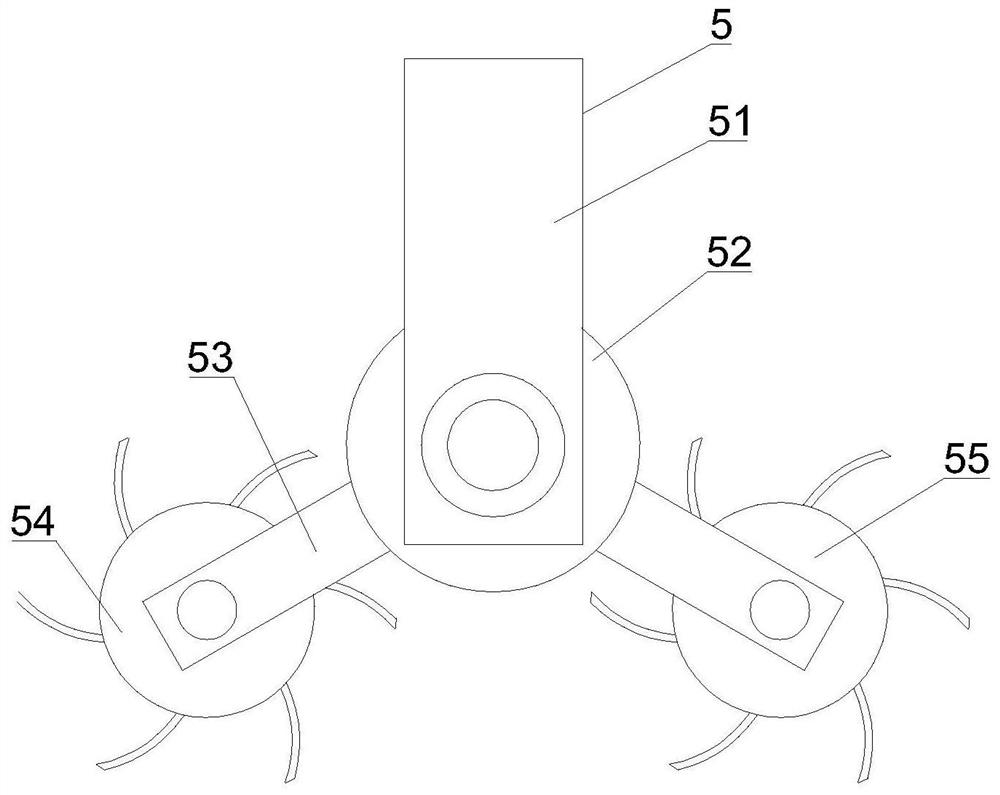

[0056] like Figure 1-15 As shown, the present invention provides a device that is beneficial to farmland trenching, including a trencher body 1, and the trencher body 1 includes a trencher 2, an elevator 3 is arranged on the outer surface of the trencher 2, and the inside of the elevator 3 Connecting rod one 4 is movably connected, and the outer surface of connecting rod one 4 is fixedly connected with excavator 5, and excavator 5 comprises support rod 51, and is fixedly connected with crawler wheel 6 on the lower surface of ditching device 2, and crawler wheel 6 comprises Bearing block 61.

[0057] In this embodiment, the cooperation between the elevator 3 and the connecting rod-4 is adopted, the connecting rod-4 is raised and lowered by the elevator 3, and the height is changed. The soil turned out is crushed, the softness of the soil is changed, the growth environment of the seeds is improved, and the crawler wheels 6 are used to move on the soil.

[0058] like Figure ...

Embodiment 2

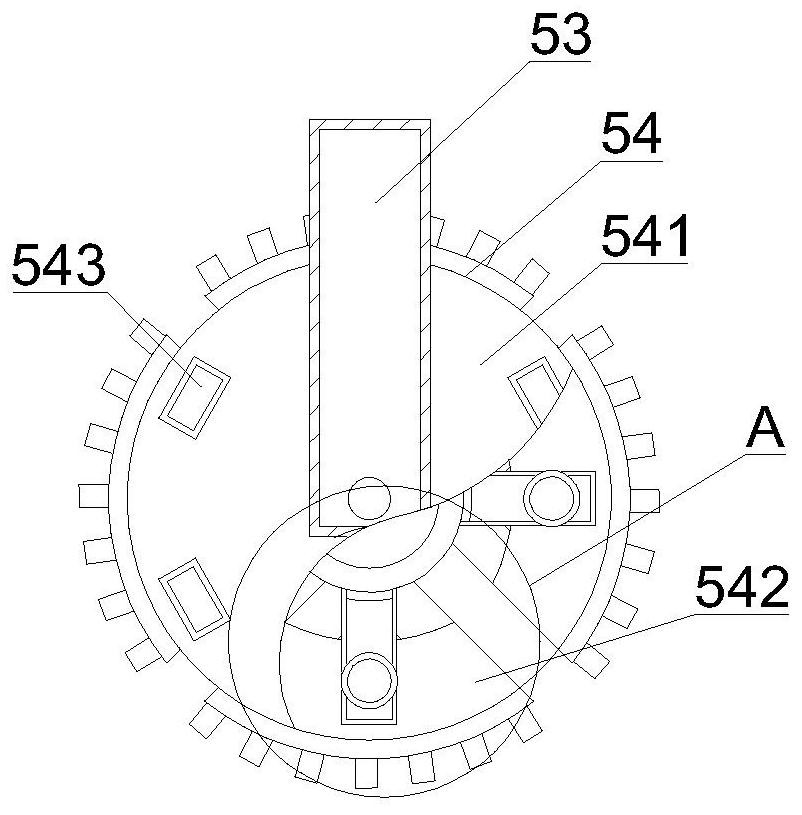

[0061] like Figure 2-9 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, the crushing wheel 54 comprises outer casing 541, and the inside of outer casing 541 is fixedly connected with breaker 542, and the inside of outer casing 541 A vibrator 543 is arranged on the outer surface. The crusher 542 includes an inner runner 5421. A telescopic sleeve 5422 is fixedly connected to the outer surface of the inner runner 5421. A fixed head 5423 is movably connected to the inside of the telescopic sleeve 5422. The outer arc block 5424 is fixedly connected on the surface, and the broken teeth 5425 are fixedly connected on the outer surface of the outer arc block 5424. The vibrator 543 includes a U-shaped shell 5431, and an oscillator 5432 is fixedly connected to the inner wall of the U-shaped shell 5431. The outer surface of 5432 is fixedly connected with buffer spring one 5433, the outer surface of buffer spring one 5433 is fixed...

Embodiment 3

[0063] like Figure 10-14 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a buffer spring 2 62 is fixedly connected to the outer surface of the bearing block 61, and a main wheel 63 is fixedly connected to one end of the buffer spring 2 62 , one end of the load-bearing block 61 is fixedly connected with an auxiliary wheel 64, the outer surfaces of the main wheel 63 and the auxiliary wheel 64 are sleeved with crawlers 65, the inner surface of the crawler belts 65 is fixedly connected with a cylindrical block 651, and the outer surface of the crawler belts 65 Fixedly connected with a friction block 652, the friction block 652 includes a trapezoidal block 6521, the interior of the trapezoidal block 6521 is fixedly connected with a V-shaped block 6522, and the outer surface of the V-shaped block 6522 is movably connected with a rotating rod 6523, and the outer surface of the rotating rod 6523 Alternate wheels 6524 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com