Full-automatic double-shaft linkage adjustment lane-dividing telescoping mechanism and method

A telescopic mechanism, fully automatic technology, applied in the field of machinery, can solve the problems of low precision, affecting the progress of production, spending a lot of time and energy, etc., to achieve the effect of improving production efficiency, shortening time, and improving adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

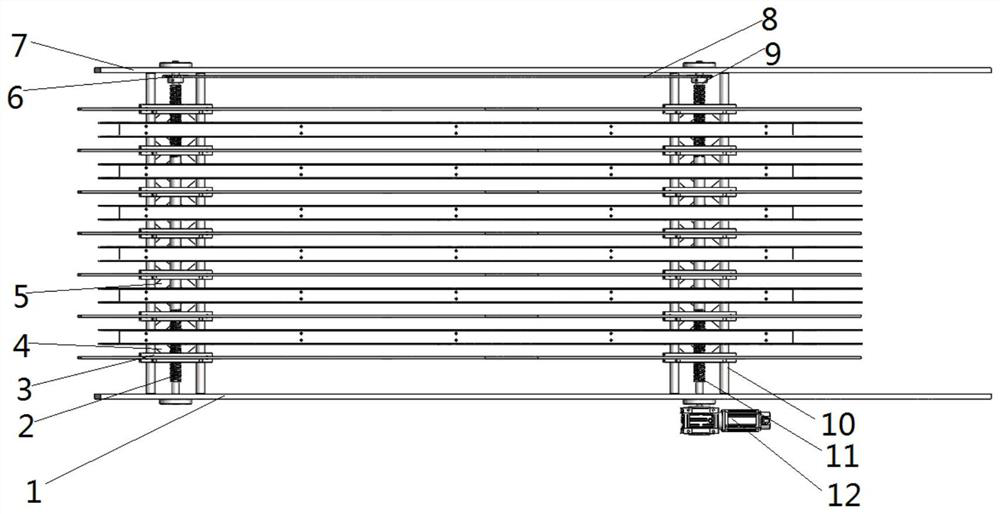

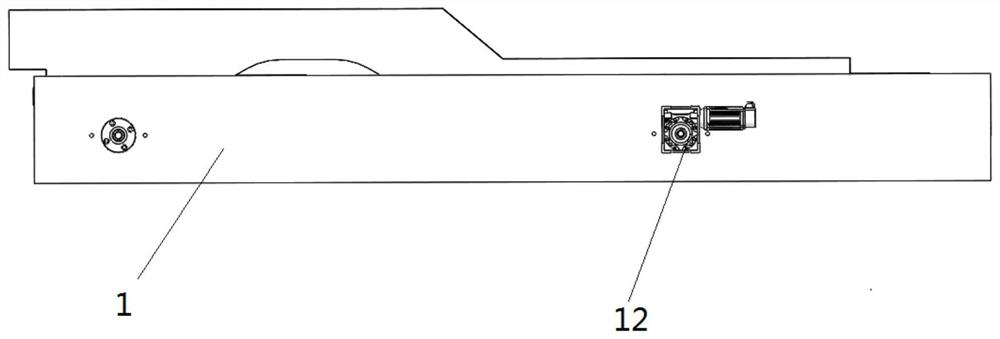

[0027] The present invention provides a technical solution: a fully automatic two-axis linkage adjustment channel separation telescopic mechanism, comprising a left side plate 7 and a right side plate 1, and a driving shaft 11 and a passive shaft are installed on the left side plate 7 and the right side plate 1 2. On the driving shaft 11 and the passive shaft 2 are installed a number of channel board bases 3 and chain track bases 13 , the channel board base 3 and the chain track base 13 are provided with guide shafts 10 , both ends of the guide shaft 10 It is fixedly connected with the left side plate 7 and the right side plate 1, the bottom of the channel plate base 3 and the chain channel base 13 is provided with a link mechanism, and the bottom of the chain channel base 13 is provided with a guide groove. The outer end of the driving shaft 11 is connected with a motor reducer 12 , the driving shaft 11 is provided with a driving sprocket 9 , and the driven shaft 2 is provided...

Embodiment 2

[0029] Based on the fully automatic dual-axis linkage adjustment lane-division telescopic mechanism and method provided in the first embodiment of the present application, the second embodiment of the present application proposes another fully automatic dual-axis linkage adjustment lane-division telescopic mechanism and method. The second embodiment is only a further mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0030] The second embodiment of the present invention will be further described below with reference to the accompanying drawings and embodiments.

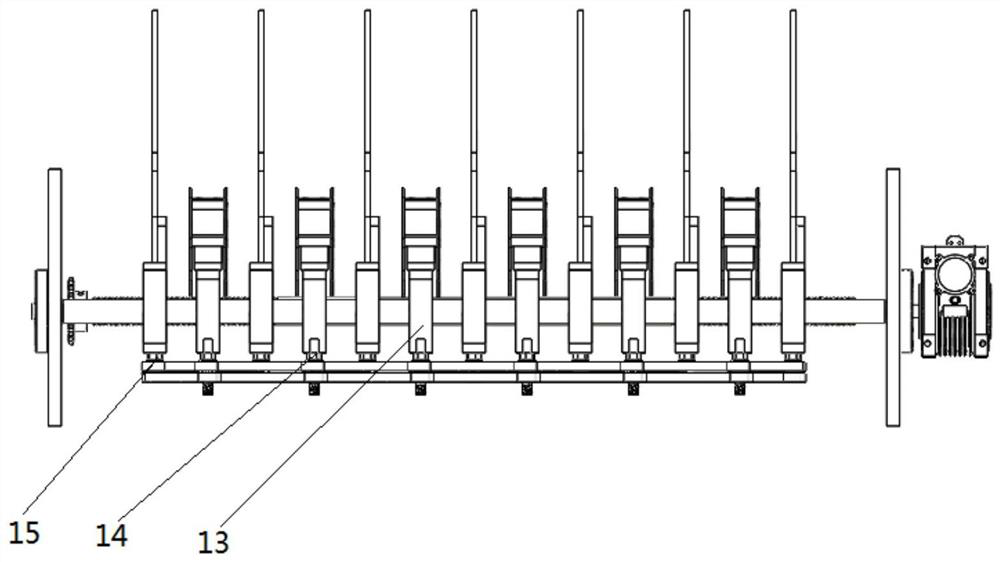

[0031] Compared with the first embodiment, this embodiment provides a specific link mechanism including several long links 5, short links 4, fixed pins 15 and push pins 14, long links 5 and short links 4. The fixed pin 15 and the push pin 14 are connected to form a link mechanism, the fixed pin 15 is installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com