Tool setting method for steel rail profile vertical inclined grinding wheel

A grinding wheel and rail technology, applied in the field of rail profile vertical oblique grinding wheel tool setting, can solve the problems of indistinguishable, difficult tool setting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

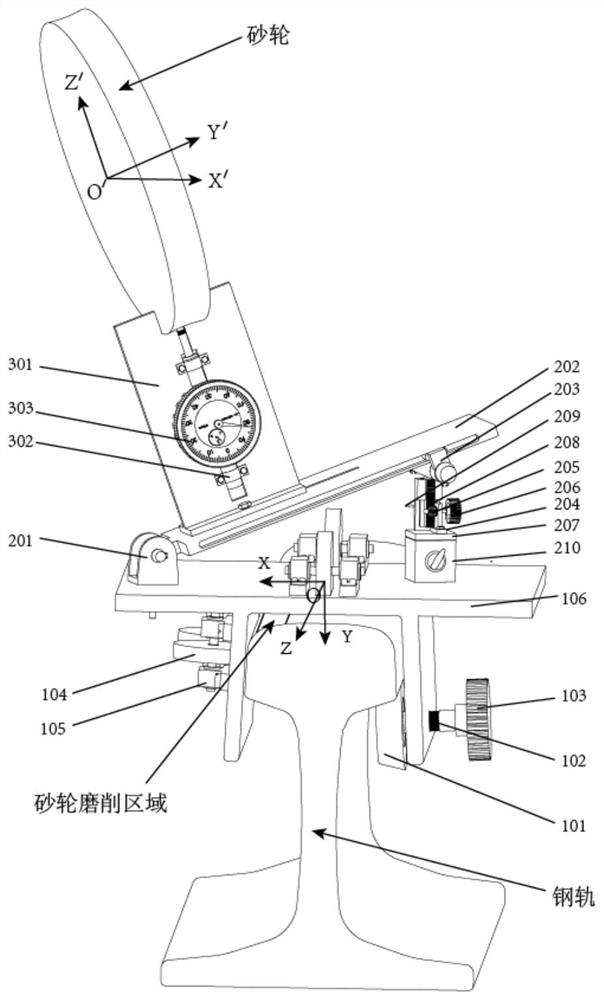

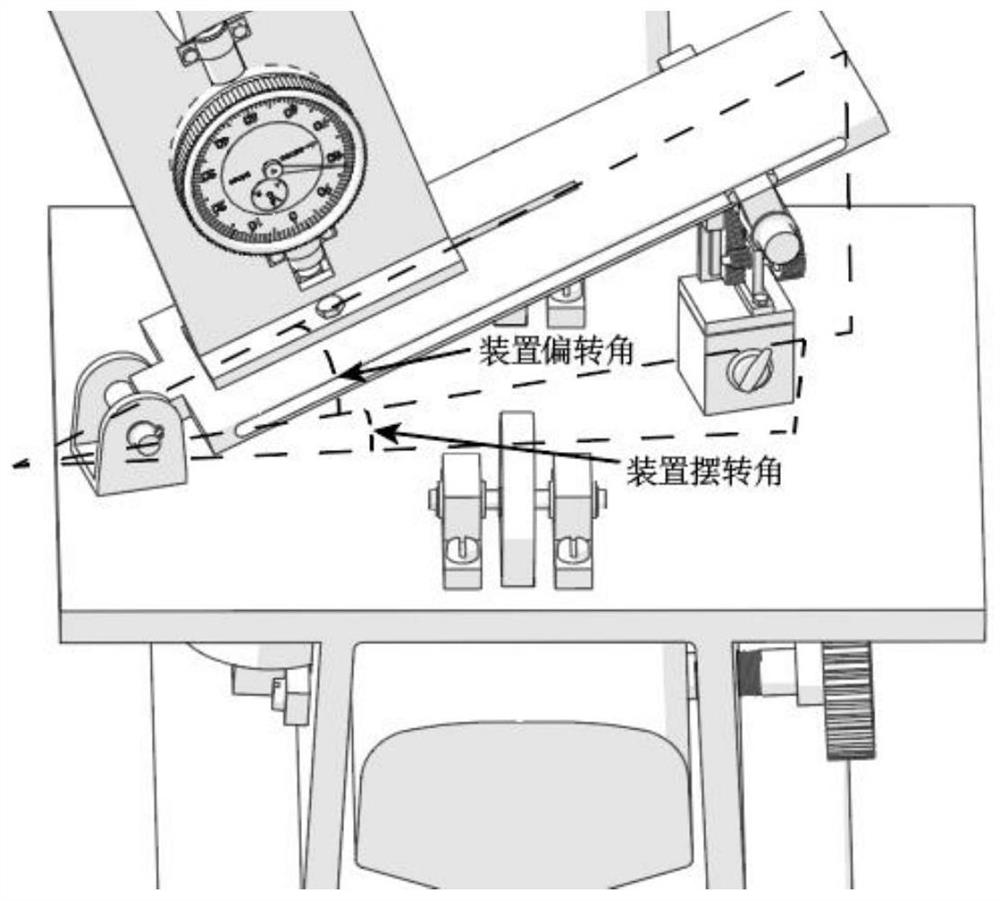

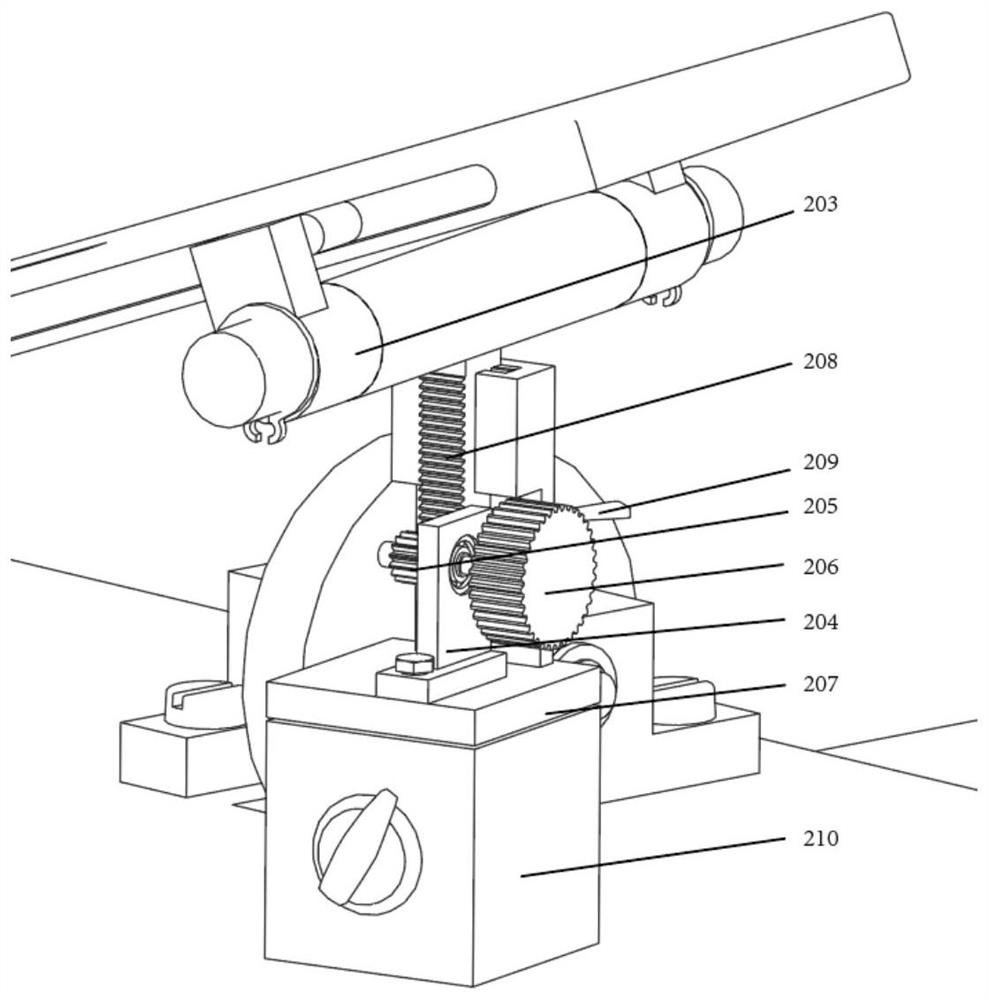

[0022] The specific technical solution of the present invention is as follows: it includes a supporting and positioning clamping mechanism, an adjusting mechanism, and a tool setting mechanism, and the supporting and positioning clamping mechanism includes a pressing roller (101), a threaded rod (102), and a pressing knob (103) , a positioning roller (104), a roller frame (105), and a base (106); the adjustment mechanism includes a connecting piece (201), a support plate (202), a sliding piece (203), a gear positioning seat (204), a gear (205), a lifting knob (206), a rack positioning seat (207), a lifting piece (208), a dish-shaped locking bolt (209), a magnetic base (210); the tool setting mechanism includes a tool setting disc (301) ), dial fixing parts (302), dial indicator (303);

[0023] The setting of the supporting and positioning clamping m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap