Steel wire phosphating and drying device

A drying device and phosphating technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of slow drying speed, low drying efficiency, and no drying, and achieve the effect of improving the effect of phosphating drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

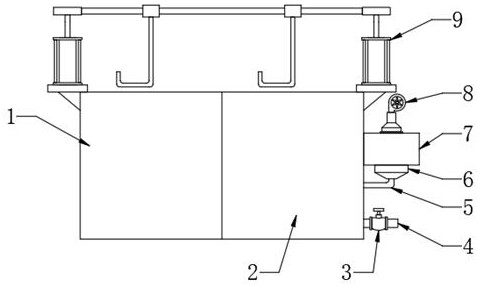

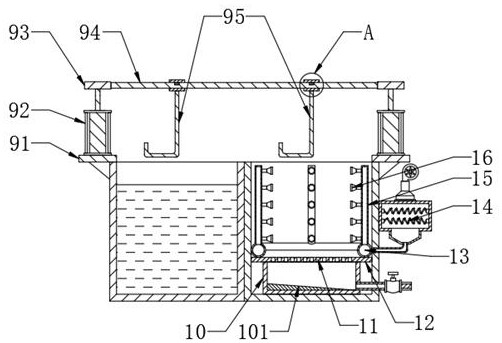

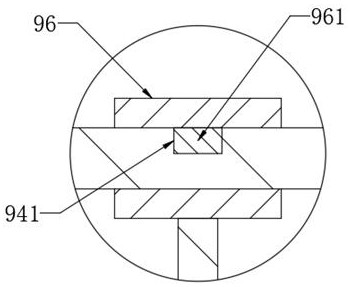

[0019] see Figure 1-Figure 4 , The present invention provides a technical solution: a steel wire phosphating drying device, comprising a phosphating box 1, a drying box 2, a manual check valve 3, a drain pipe 4, a connecting air pipe 5 and an air collecting shroud 6 , a drying box 2 is installed on the right side of the phosphating box 1, a hanging assembly 9 is installed on the upper side of the drying box 2 and the phosphating box 1, a heating box 7 is installed on the right end surface of the drying box 2, and a heating box 7 is installed on the upper side of the heating box 7 The blower 8 and the heating box 7 are provided with an air collecting shroud 6 on the lower side, and a supporting bottom plate 12 is laterally mounted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com