Phosphorization metal powder spraying technology process

A process flow and metal powder technology, applied in the field of metal powder processing, can solve the problems of poor spraying effect of working layer, slow phosphating reaction rate, reduced work efficiency, etc., and achieve the effect of good phosphating effect, good spraying and keeping clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

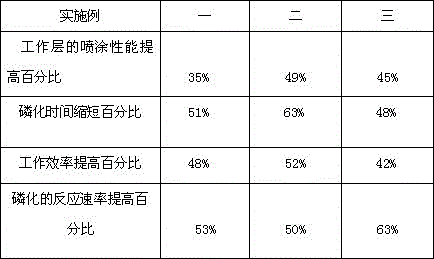

Examples

Embodiment 1

[0030] A kind of phosphide metal powder spraying technological process is proposed in the present embodiment, comprises the following steps:

[0031] S1: select the metal with block structure as the matrix;

[0032] S2: The matrix described in S1 is placed in NH 4 CL solution, and NH 4 The temperature of the CL solution is set to 20°C, when the NH 4 out of the CL solution;

[0033] S3: Place the substrate described in S2 in hot water at 40°C, clean the surface of the substrate with hot water, and take out the substrate from the hot water after 10 minutes;

[0034] S4: The matrix described in S3 is placed in a carboxyl polymer solution at 50° C., and the carboxyl polymer solution is used to degrease the matrix. After 5 minutes, the matrix is taken out from the carboxyl polymer solution;

[0035] S5: The substrate described in S4 can be transported to the position of the high-pressure water gun through the conveyor chain, and the high-pressure water gun uses a pressure of ...

Embodiment 2

[0044] A kind of phosphide metal powder spraying technological process is proposed in the present embodiment, comprises the following steps:

[0045] S1: select the metal with block structure as the matrix;

[0046] S2: The matrix described in S1 is placed in NH 4 CL solution, and NH 4 The temperature of the CL solution is set to 25°C, when the NH 4 out of the CL solution;

[0047] S3: The substrate described in S2 is placed in hot water at 60°C, and the surface of the substrate is cleaned with hot water, and the substrate is taken out of the hot water after 13 minutes;

[0048] S4: The matrix described in S3 is placed in a carboxyl polymer solution at 55° C., and the carboxyl polymer solution is used to degrease the matrix. After 8 minutes, the matrix is taken out from the carboxyl polymer solution;

[0049] S5: The substrate described in S4 can be transported to the position of the high-pressure water gun through the conveyor chain, and the high-pressure water gun uses...

Embodiment 3

[0058] A kind of phosphide metal powder spraying technological process is proposed in the present embodiment, comprises the following steps:

[0059] S1: select the metal with block structure as the matrix;

[0060] S2: The matrix described in S1 is placed in NH 4 CL solution, and NH 4 The temperature of the CL solution is set to 30°C, when the NH 4 out of the CL solution;

[0061] S3: The substrate described in S2 is placed in hot water at 80°C, and the surface of the substrate is cleaned with hot water, and the substrate is taken out of the hot water after 15 minutes;

[0062] S4: The matrix described in S3 is placed in a carboxyl polymer solution at 60°C, and the carboxyl polymer solution is used to degrease the matrix, and the matrix is taken out from the carboxyl polymer solution after 10 minutes;

[0063] S5: The substrate described in S4 can be transported to the position of the high-pressure water gun through the conveyor chain, and the high-pressure water gun us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com