Backlight module and display device

A technology for backlight modules and optical components, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficulty in promoting the development of borderless liquid crystal display devices and the width of the frame, and achieve the effect of increasing the area and expanding the light-emitting area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

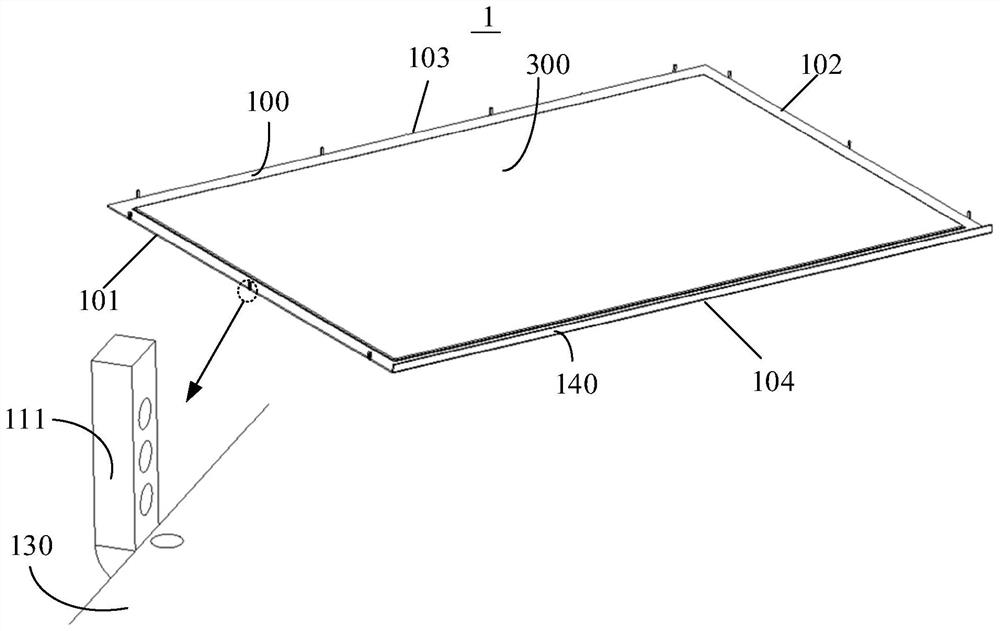

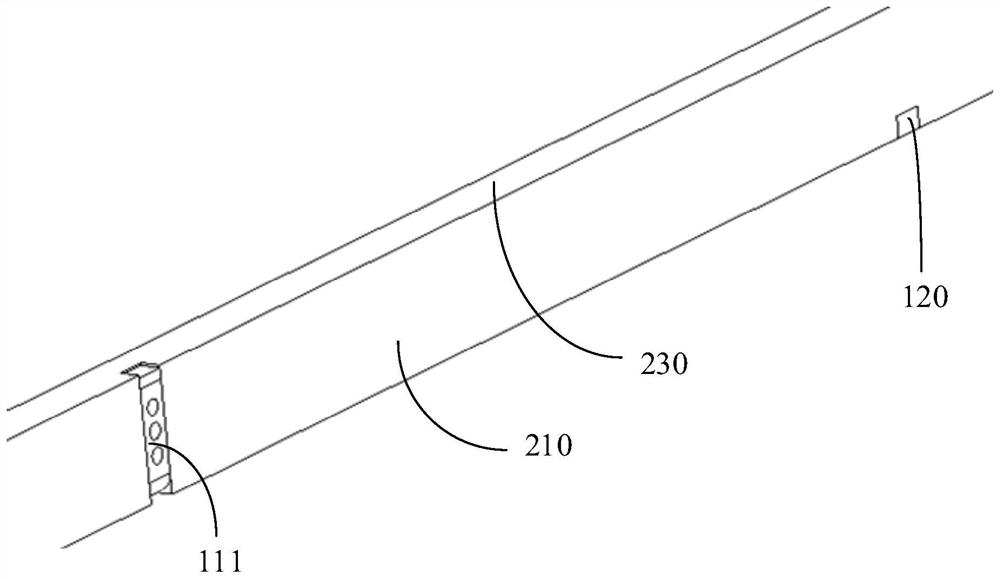

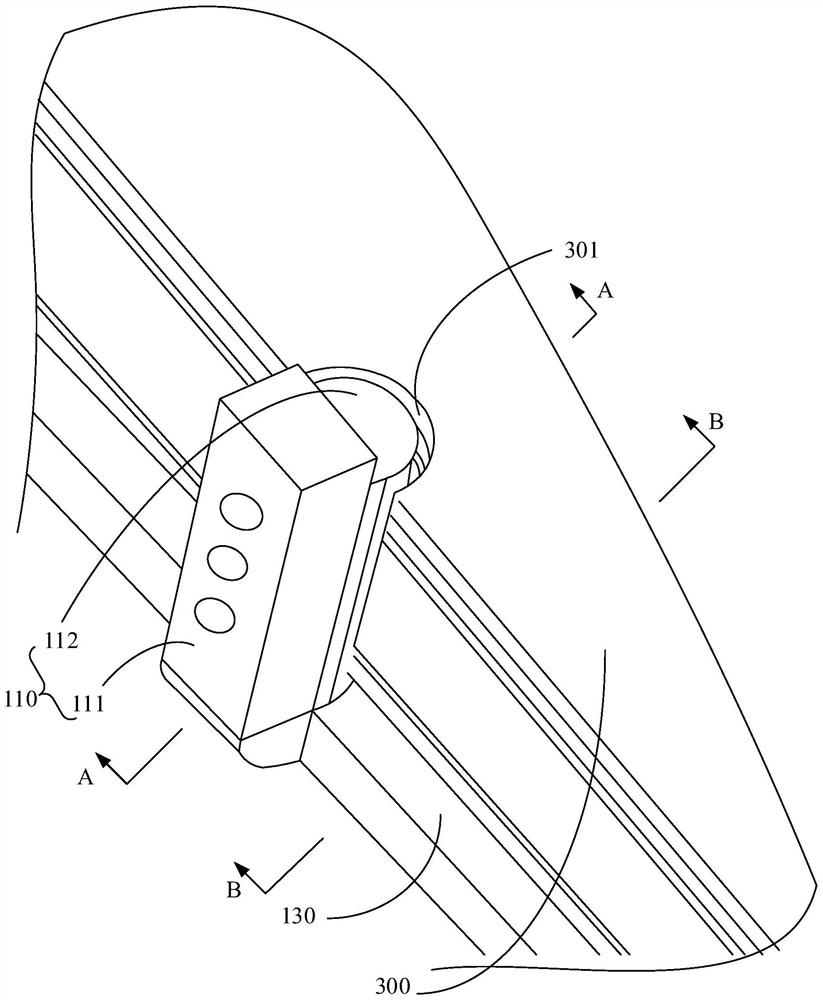

[0036] In the embodiments of this application, please refer to figure 1 and figure 2 , the backlight module 1 includes a backplane 100, a middle frame 200 and an optical assembly, the backplane 100 includes a bottom plate 130, the middle frame 200 includes a support plate 230 and a side plate assembly, the support plate 230 is arranged opposite to the bottom plate 130, and the side plate assembly is connected At the edge of the support plate 230 and extending toward the direction of the bottom plate 130, the bottom plate 130, the support plate 230 and the side plate components together form an installation space, the optical components are arranged in the installation space, and a part of the edge of at least one side of the bottom plate 130 is formed. A blocking wall assembly 110 is protruded toward the direction of the support plate 230 , and an escape space is formed above the other part of the edge; The optical component includes an optical film 300, a part of the edge o...

Embodiment 2

[0068] The present application also proposes a display device, such as Figure 8 As shown, the display panel 2 includes a display panel 2 and a backlight module 1, and the specific structure of the backlight module 1 refers to the above-mentioned embodiments. All the beneficial effects brought by the technical solutions of the examples are not repeated here. The backlight module 1 is disposed on the light incident side of the display panel 2 to provide a light source to the display panel 2 . Specifically, the display panel 2 may be directly adhered to the support plate 230 of the middle frame 200 by double-sided tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com