Intelligent gearbox fault diagnosis method based on multi-channel self-calibration convolutional neural network

A convolutional neural network and fault diagnosis technology, applied in neural learning methods, biological neural network models, neural architectures, etc. The effect of reducing the probability of fault diagnosis errors and reducing the use of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

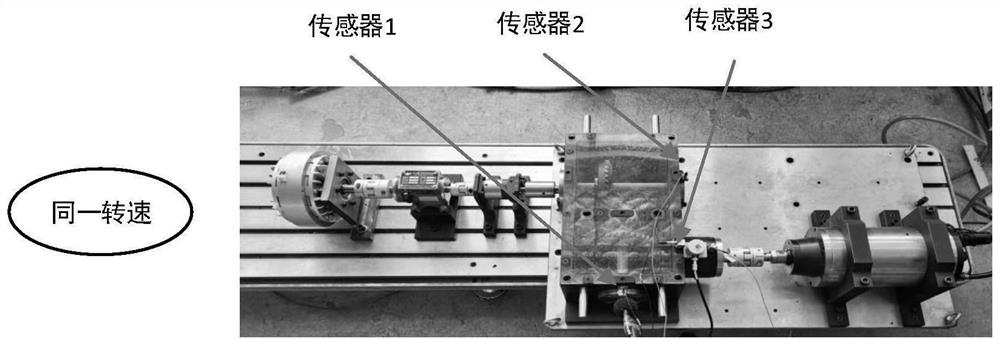

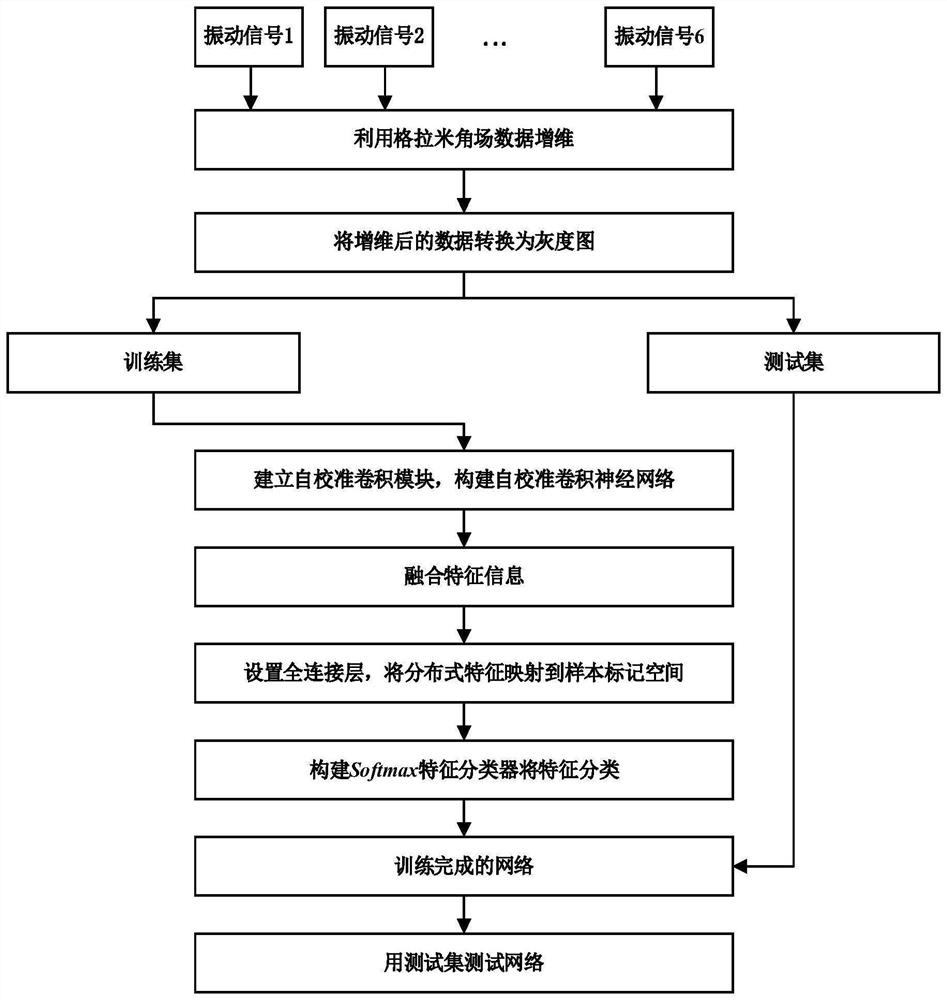

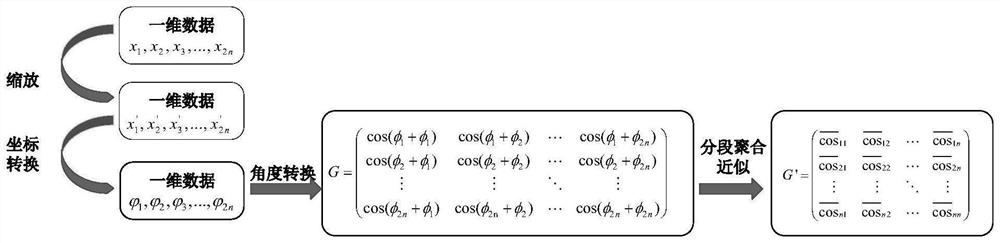

[0061] The invention provides an intelligent fault diagnosis method for a gearbox based on a multi-channel self-calibration convolutional neural network, which combines information fusion and a self-calibration convolutional neural network to perform effective fault diagnosis for a single fault of the gearbox under the same rotational speed condition. Including: after the dimensional increase of the Grammy angle field data, the one-dimensional vibration signals measured by multiple sensors are converted into two-dimensional data, and the two-dimensional data is converted into a grayscale image as input, and a data set is established and divided into training set and test set. Build a self-calibration convolution module, build a self-calibration convolutional neural network, and extract data features. Set the fusion layer to convert the output of the self-calibration convolutional neural network into one-dimensional data and fuse the feature information. Set up fully connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com