Support pile construction method based on mortise and tenon joint structure

A construction method and technology for supporting piles, which are applied in basic structure engineering, excavation, sheet pile walls, etc., can solve the problems of long construction period and general construction quality, and achieve the improvement of finished product quality, good structural strength and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

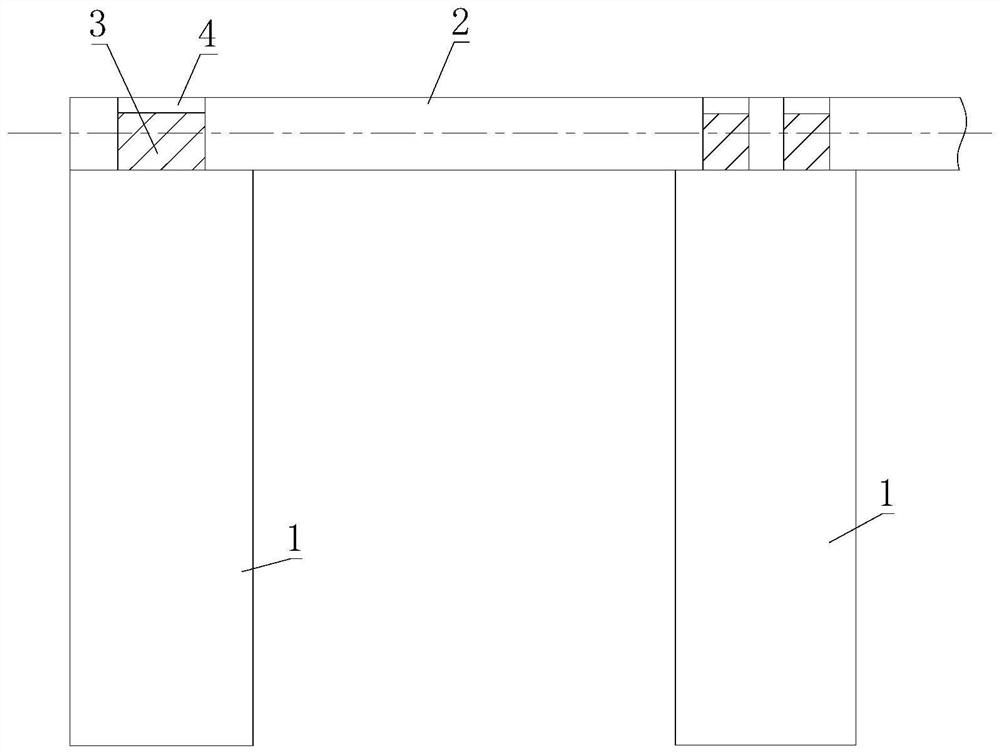

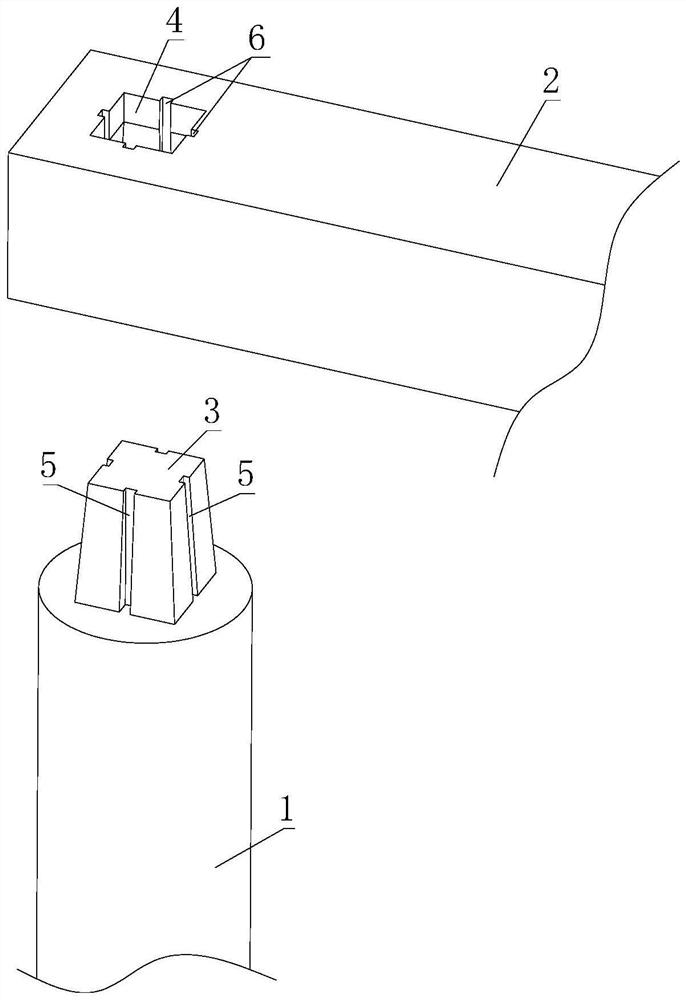

[0022] like figure 1 and 2 As shown, a method for constructing a retaining pile based on a tenon-and-mortise structure comprises the following steps:

[0023] Step 1: The vertical retaining piles 1 of the construction supporting piles are poured on site by means of artificial digging piles and mechanical hole forming, and the tenon 3 shape is poured on the top of the retaining piles 1; The transverse crown beam 2 of the pile guard, the crown beam 2 is formed with a socket 4 that matches the tenon. In this implementation, the tenon 3 is preferably cast into a trapezoidal table structure, and the lower part of the socket 4 is constructed into a trapezoidal hole shape.

[0024] In step 1, the pouring of the retaining pile 1 and the pouring of the tenon 1 may be completed in one pouring construction, or may be constructed in two steps. Regardless of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com